Method for installing large pipe fittings in narrow space

An installation method and narrow space technology, which is applied in the field of installation of large pipe fittings in narrow spaces, can solve the problems of narrow culvert space and inability to install large pipe fittings in place, and achieve the effects of high safety, shortened construction and installation time limit, and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below.

[0017] A method for installing large pipe fittings in a narrow space, comprising the following steps

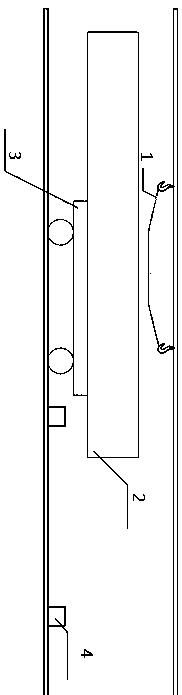

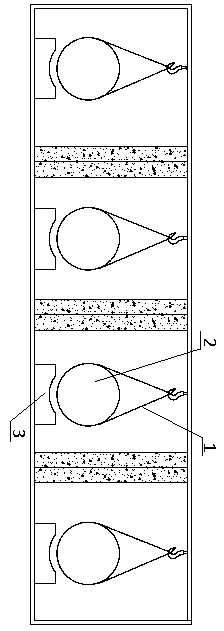

[0018] Step 1: Install two sets of manual hoist lifting brackets at the position where the pipe fittings are to be installed in the culvert, and place the pipe pillow on the wall of the culvert;

[0019] Step 2: Use the lifting equipment to transport the pipe fittings to the culvert opening, extend into the culvert opening, and extend the distance to at least 1 / 2 of the pipe length, and place the extended ones on the trackless car;

[0020] Step 3: Use the trackless trolley equipment to transport the pipe fittings to the installation position of the hidden culvert pipe fittings;

[0021] Step 4: Use two sets of manual hoist lifting brackets to lift the pipe to the same height and remove the trackless trolley;

[0022] Step 5: Pull the two groups of hoists at the same time, so that the two pipe fittings are slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com