Hoisting device for heavy drilling tool

A drilling tool and heavy-duty technology, which is applied to the field of lifting devices for heavy drilling tools, can solve the problems of gantry cranes with high lifting height, high labor intensity, and impact on operation efficiency, and achieves safe lifting, low labor intensity, and reduced operation labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

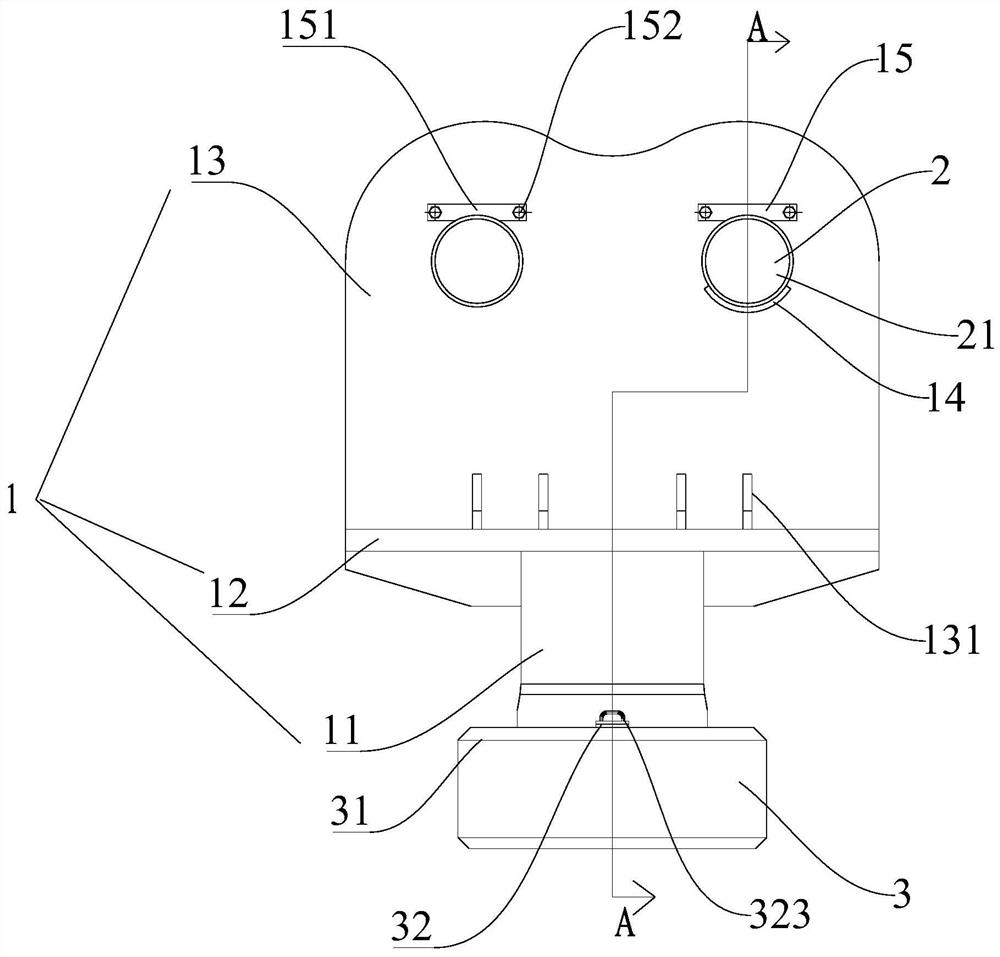

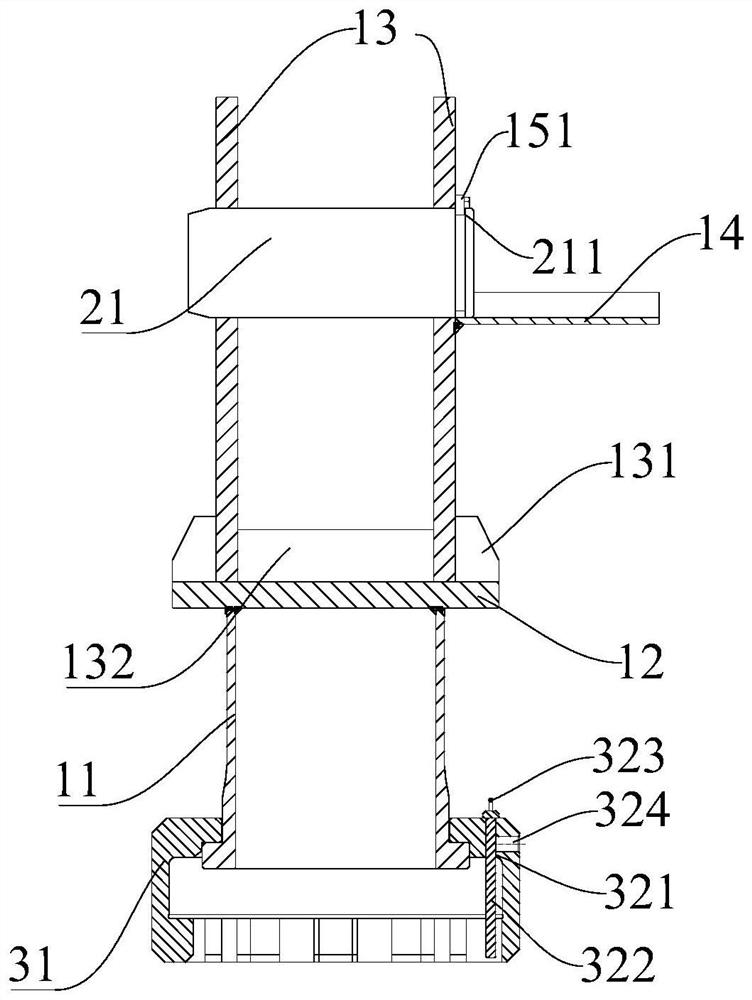

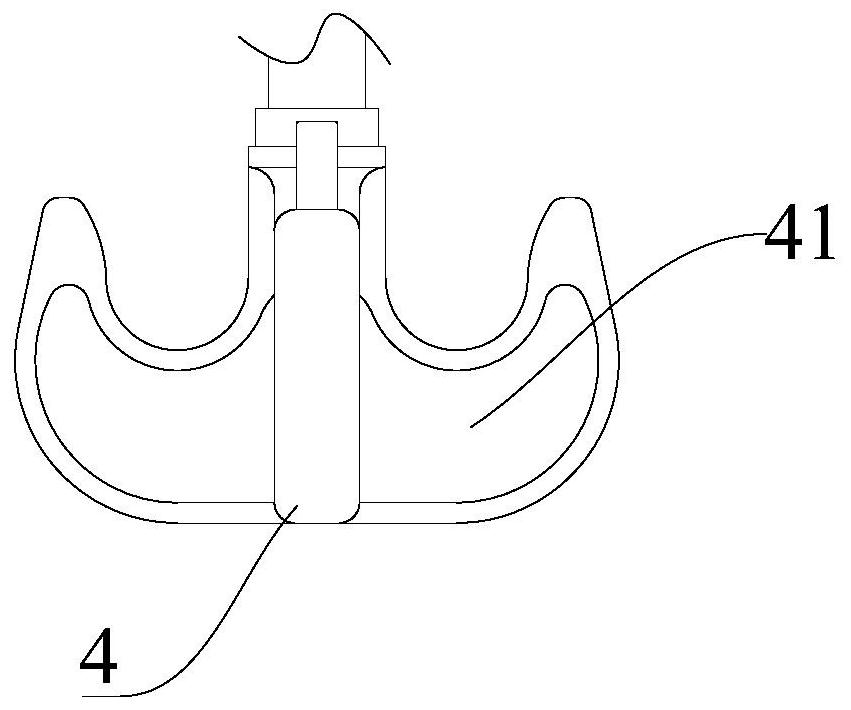

[0043] Such as Figure 1-10 As shown, a lifting device for a heavy-duty drilling tool in this embodiment is specially used for lifting a drilling tool of a large shaft drilling rig, and includes a lifting tool main body 1 , a crane connecting part 2 and a hanging object connecting part 3 . The main body 1 of the spreader includes a cylinder body 11, a horizontal plate 12 is connected to the upper end of the cylinder body 11, and two vertical plates 13 opposite to each other are installed on the horizontal plate 12. The crane connector 2 includes two pin shafts 21; the two pin shafts 21 are inserted horizontally between the two vertical plates 13, and are articulated and matched with the hook head 4 of the gantry crane. The hanging object connector 3 includes a hanging pan 31; the hanging pan 31 is installed at the lower end of the cylinder body 11, and the opening 311 of the hanging pan 31 is downward; the opening 311 is clamped and fitted with the upper interface 5 of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com