Underneath type water dispenser and underneath type water dispenser provided with shrink packaging bucket and application method thereof

A shrink packaging and water dispenser technology, applied in the field of water dispensers, can solve the problem of the weight of 20 packed buckets, reduce residual water, and overcome warpage and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

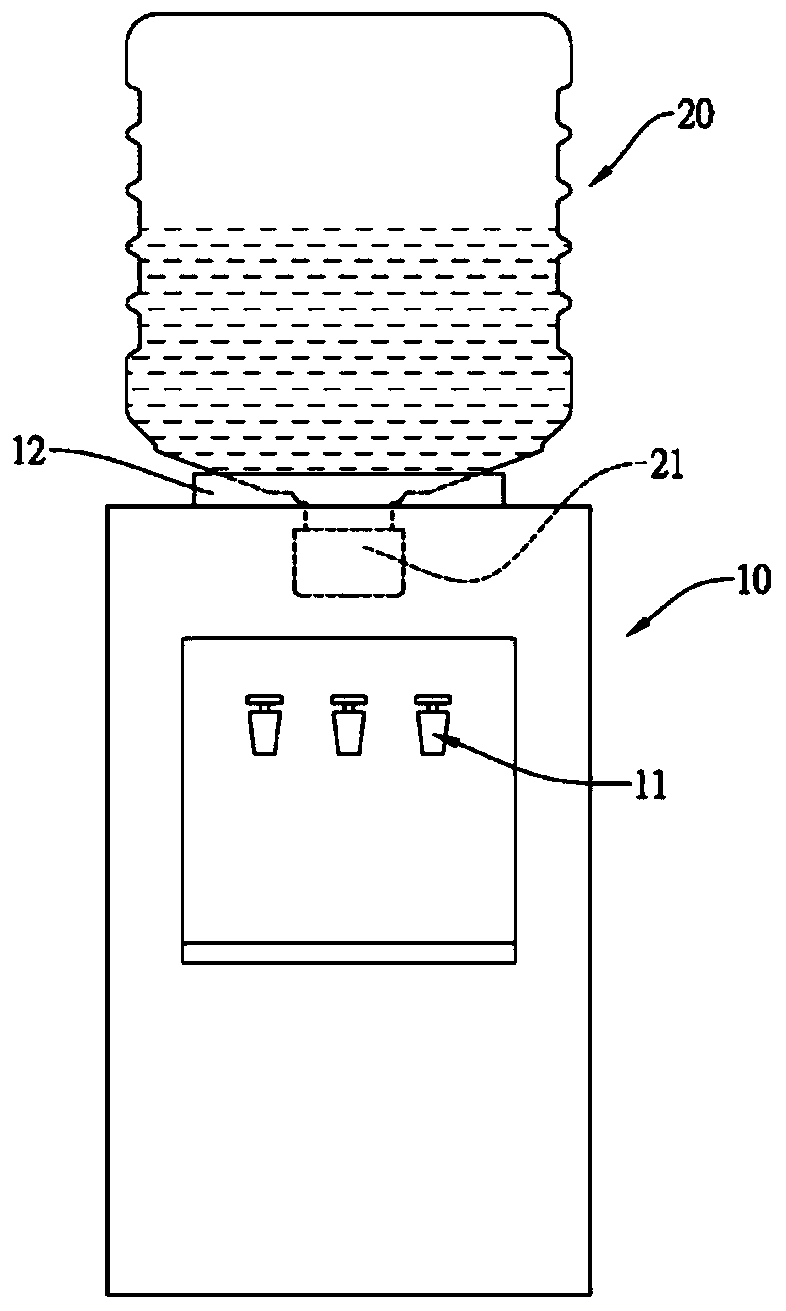

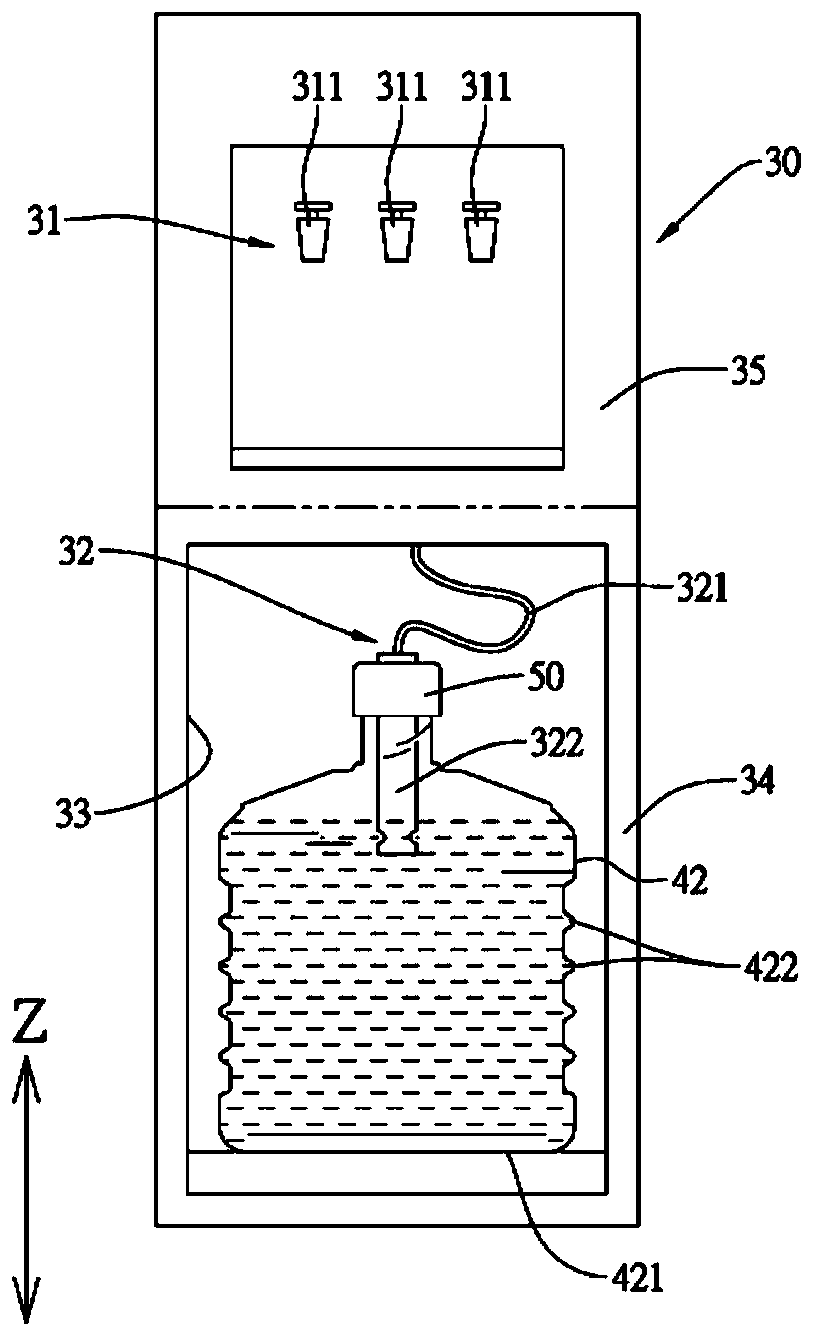

[0054] The present invention provides a kind of bottom type water dispenser, such as Figures 2 to 5 shown, including:

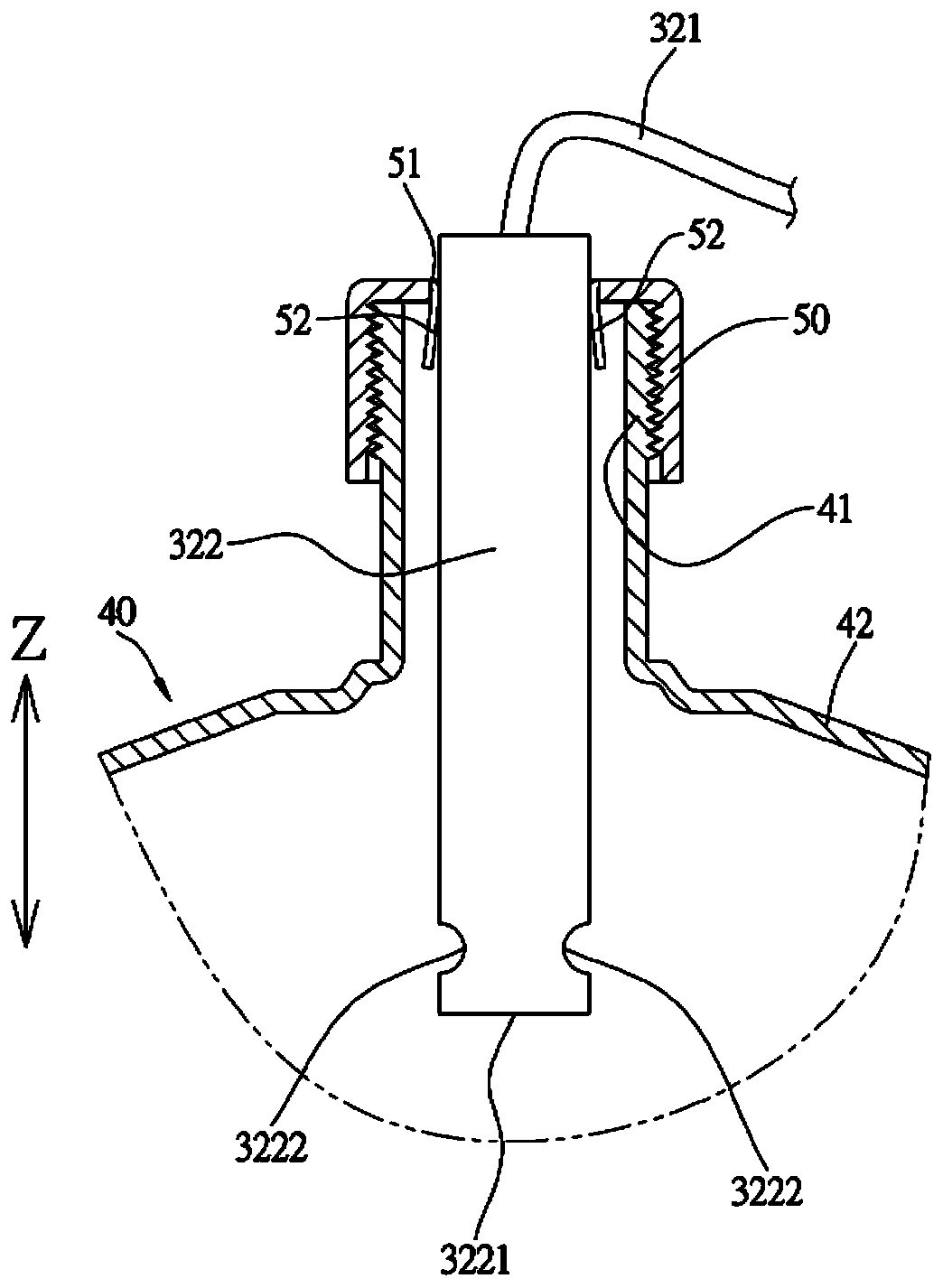

[0055] The main body 30 has a water outlet part 31, a water absorption part 32 and an accommodating tank 33. The main body 30 is divided into a first area 34 and a second area 35. The first area 34 is closer to the ground than the second area 35, defining the first area 34 and the second area. The extension direction between the two areas 35 is the vertical direction Z, the accommodating groove 33 is arranged in the first area 34 of the body 30, and the water outlet 31 is arranged in the second area 35, and the water outlet 31 has a plurality of water outlets 311, each The water outlet 311 communicates with the water absorbing part 32, so that the water outlet 31 communicates with the water absorbing part 32, the water absorbing part 32 is arranged in the housing tank 33, and the water absorbing part 32 has a water absorbing hose 321 and a water absorbing ha...

Embodiment 2

[0066] In order to further reduce the residue of drinking water, in the second embodiment of the present invention, a fixing frame 60 is also included, such as Figures 9 to 11 As shown, the fixed frame 60 is arranged in the accommodating groove 33, and the shrink-wrapped bucket 40 is provided for placing on the fixed frame 60. The fixed frame 60 has a bottom wall 61 and a peripheral wall 62 connecting the bottom wall 61, and the peripheral wall 62 and the bottom wall 61 The extension direction is roughly vertical, the bottom wall 61 and the peripheral wall 62 together surround the space 63, the top 3221 of the water-absorbing hard tube 322 faces and aligns with the space 63, the other end of the peripheral wall 62 connected to the bottom wall 61 is the supporting end 621, and the supporting end 621 is against the bottom 421, so that the central area 421A faces the space 63, and the peripheral area 421B is located outside the space 63. When the shrink-wrapped bucket 40 is fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com