Annular multiple node type welding device based on electromechanical control and use method thereof

A welding device and electromechanical control technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of wasting manpower, difficult circular multi-point welding, and reducing work efficiency, so as to improve automatic operation and improve the flexibility of electric welding Performance and efficiency, the effect of improving the support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

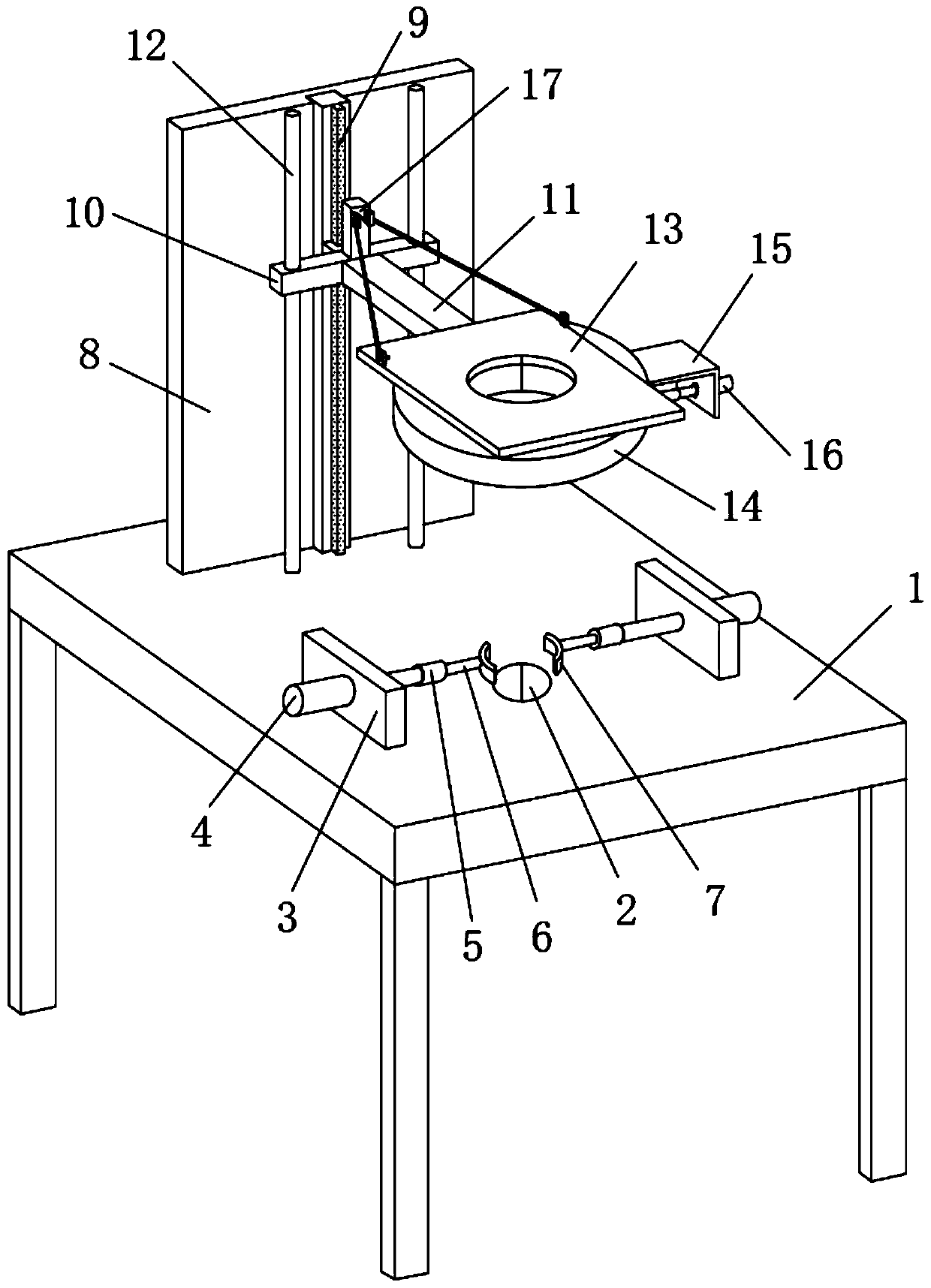

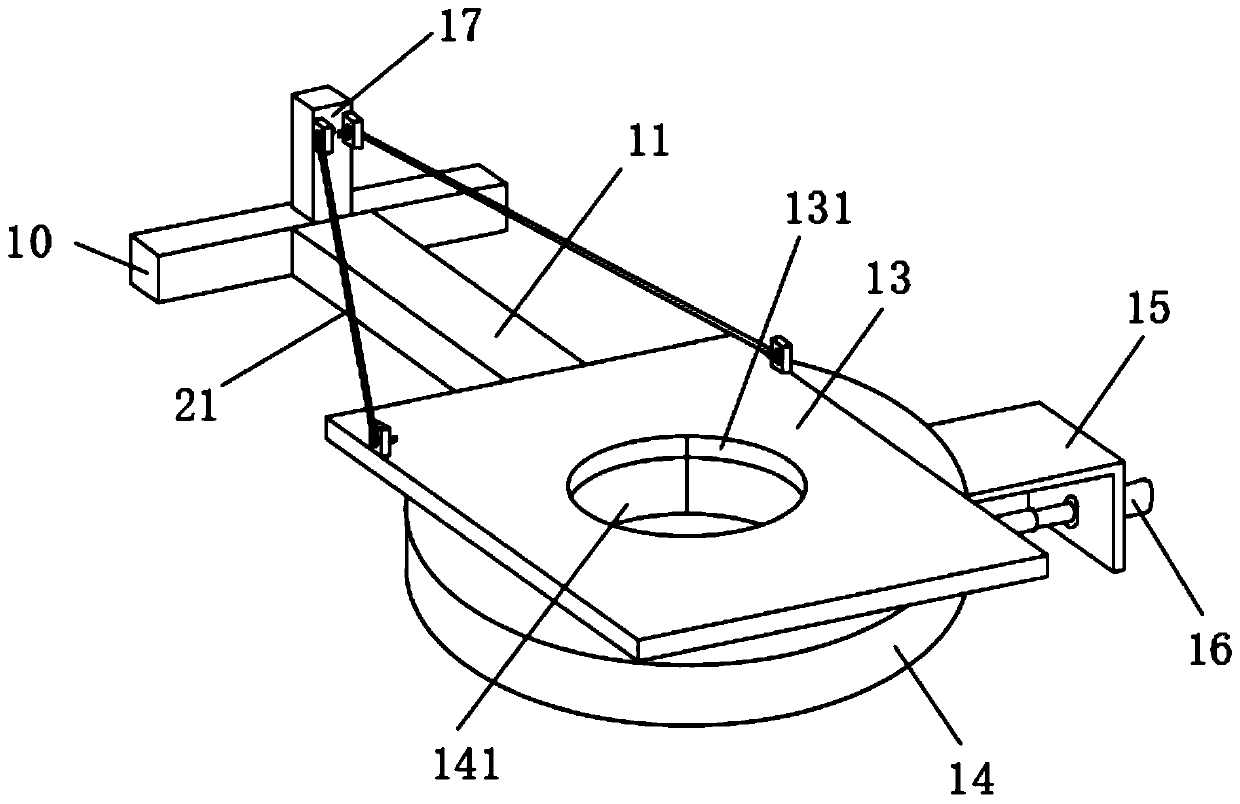

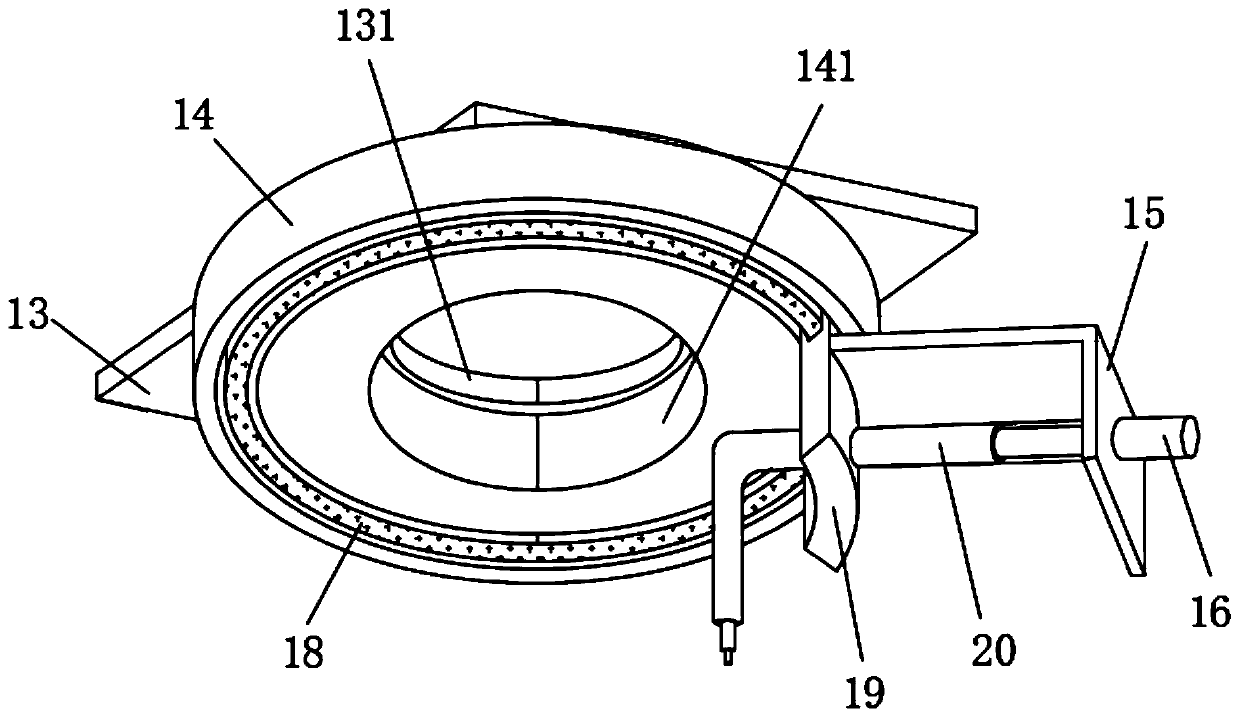

[0039] see figure 1 and Figure 5 , a ring-shaped multi-node welding device based on electromechanical control, including an operating table 1, a workpiece sleeve hole 2 is opened in the middle of the front end of the operating table 1, and the workpiece sleeve hole 2 is used to sleeve the workpiece steel pipe. 1. The two sides of the front end are fixedly equipped with workpiece limit mechanisms symmetrically arranged on both sides of the workpiece sleeve hole 2. A pair of workpiece limit mechanisms realize the limit and fixation of the workpiece to be welded. The fixed plate 3, the outer wall of the fixed plate 3 is fixedly connected with an electric push rod 4, the telescopic end of the electric push rod 4 runs through the fixed plate 3 and is fixedly connected with a workpiece limit block 7, a pair of workpiece limit blocks 7 are in a The electric push rods 4 are pushed closer to each other to clamp and limit the workpiece, and the workpiece limit block 7 can be replaced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com