Fiber wheel grinding polishing machine

A technology of polishing machine and grinding jig, which is applied in the field of zipper polishing, which can solve the problems of high friction on the zipper surface and easy dripping on the machine, and achieve the effect of maintaining brightness and neat brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

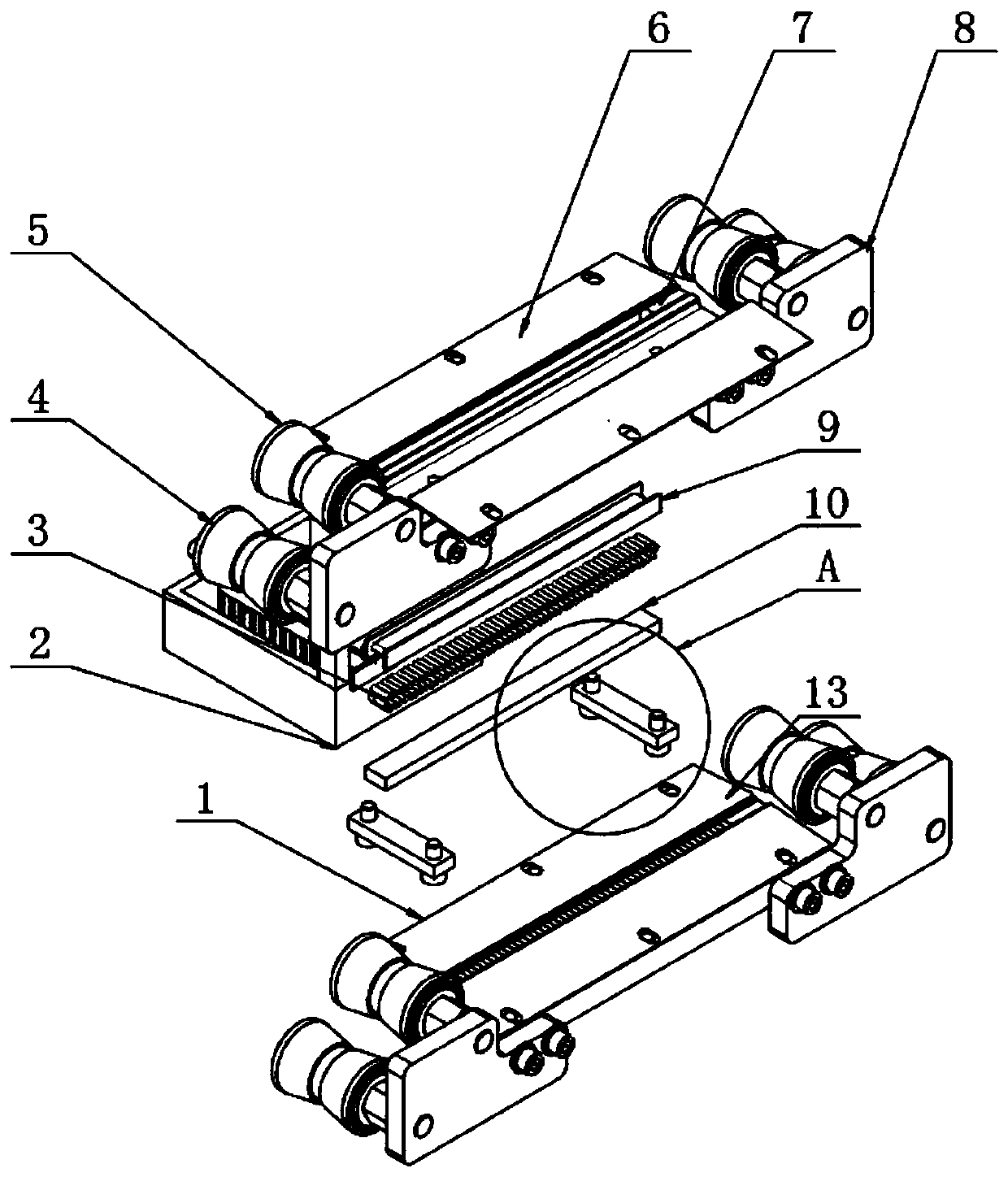

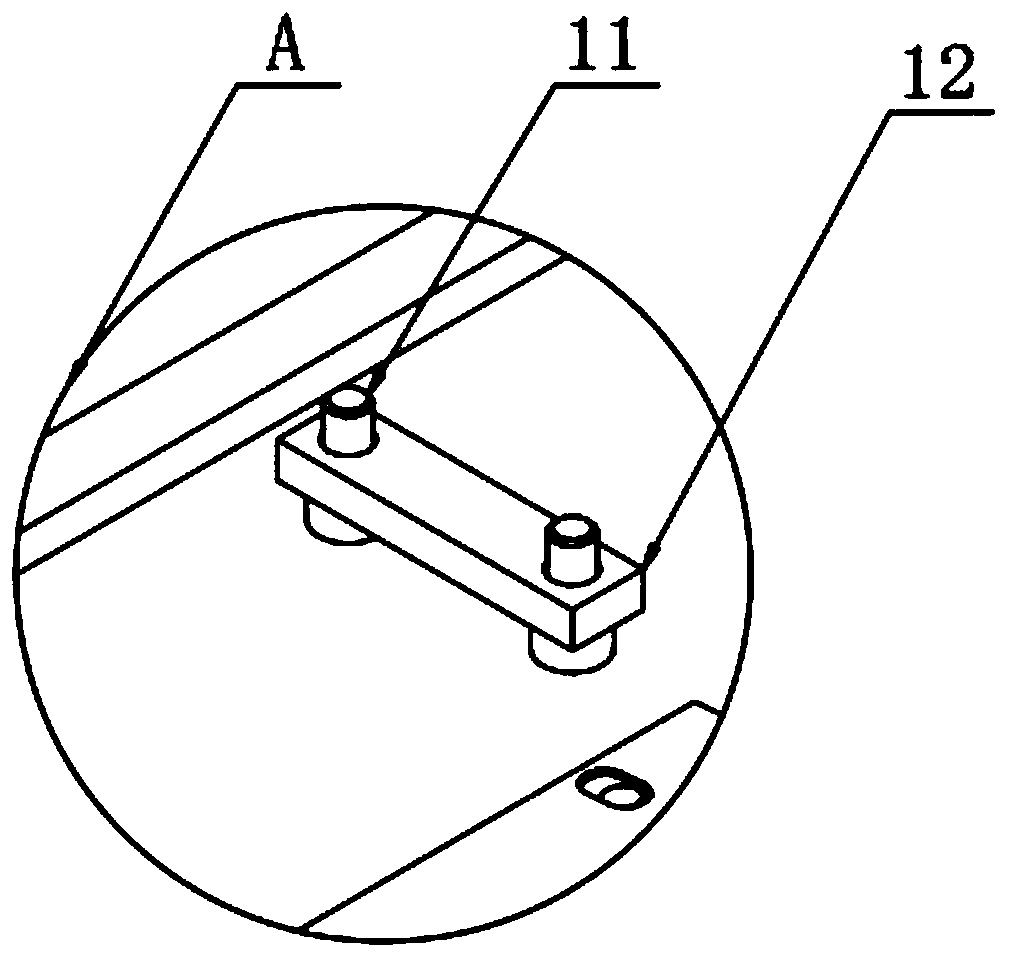

[0017] see Figure 1~3 , in an embodiment of the present invention, a polishing fixture device includes a base 8, the upper surface of the base 8 is fixedly equipped with a zipper groove 7, the upper surface of the zipper groove 7 is movably connected with a manganese sheet cover plate 6, and the other part of the base 8 One end is rotatably connected with a second sprocket wheel 5 , and the first sprocket wheel 4 is rotatably arranged below the second sprocket wheel 5 .

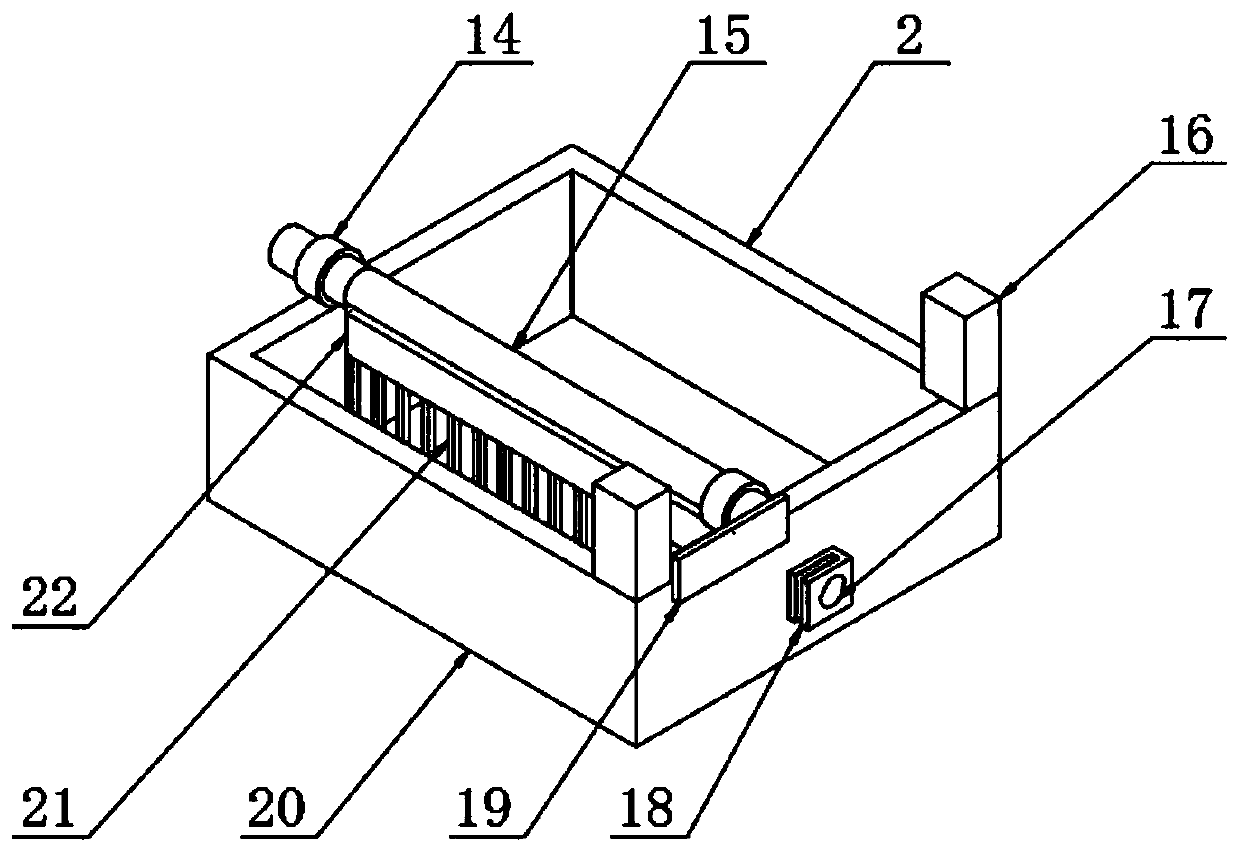

[0018] exist figure 1 and 2 Middle: The lower surface of the base 8 is fixedly connected with a polishing liquid adding assembly 2, which includes a collar 14, a rotating shaft 15, a connecting column 16, a second limit bolt 17, a card slot 18, a card 19, and a box body 20 , bristles 21 and brush rod 22, the upper surface of the box body 20 is fixedly installed with a connecting column 16, and the front surface of the box body 20 is fixedly installed with a card slot 18, and the front surface of the card s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com