Efficient horizontal centrifugal grinding machine

A grinding machine, horizontal technology, applied in the field of grinding machines, can solve the problems of wasting working time, inconvenient observation, and unable to place the grinding machine stably, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

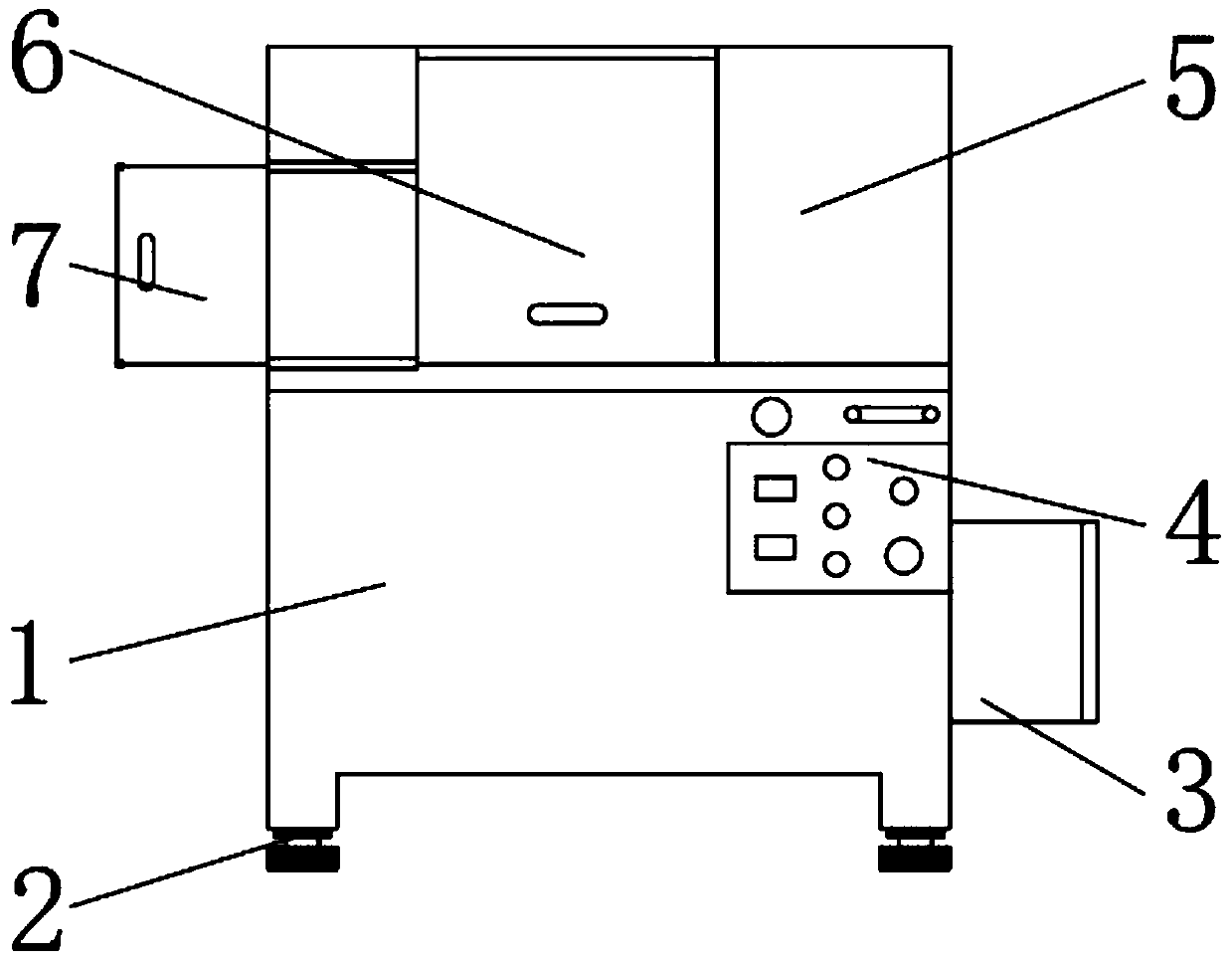

[0022] Such as figure 1 Figure 5 As shown, a high-efficiency horizontal centrifugal grinder, a high-efficiency horizontal centrifugal grinder, includes a centrifugal grinder main body 1, the outer surface of the lower end of the centrifugal grinder main body 1 is provided with a smooth adjustment structure 2, and the centrifugal grinder main body 1 An electrical box 3 is fixedly installed on the outer surface of one side, a control panel 4 is arranged on the outer surface of the front end of the main body 1 of the centrifugal grinder, and a grinding tool room 5 is arranged on the outer surface of the upper end of the main body 1 of the centrifugal grinder, and the middle outer surface of the grinding tool room 5 A dust-proof protective door 6 is provided, and an isolation observation structure 7 is provided on the outer surface of the front end of the grinding tool chamber 5 .

Embodiment 2

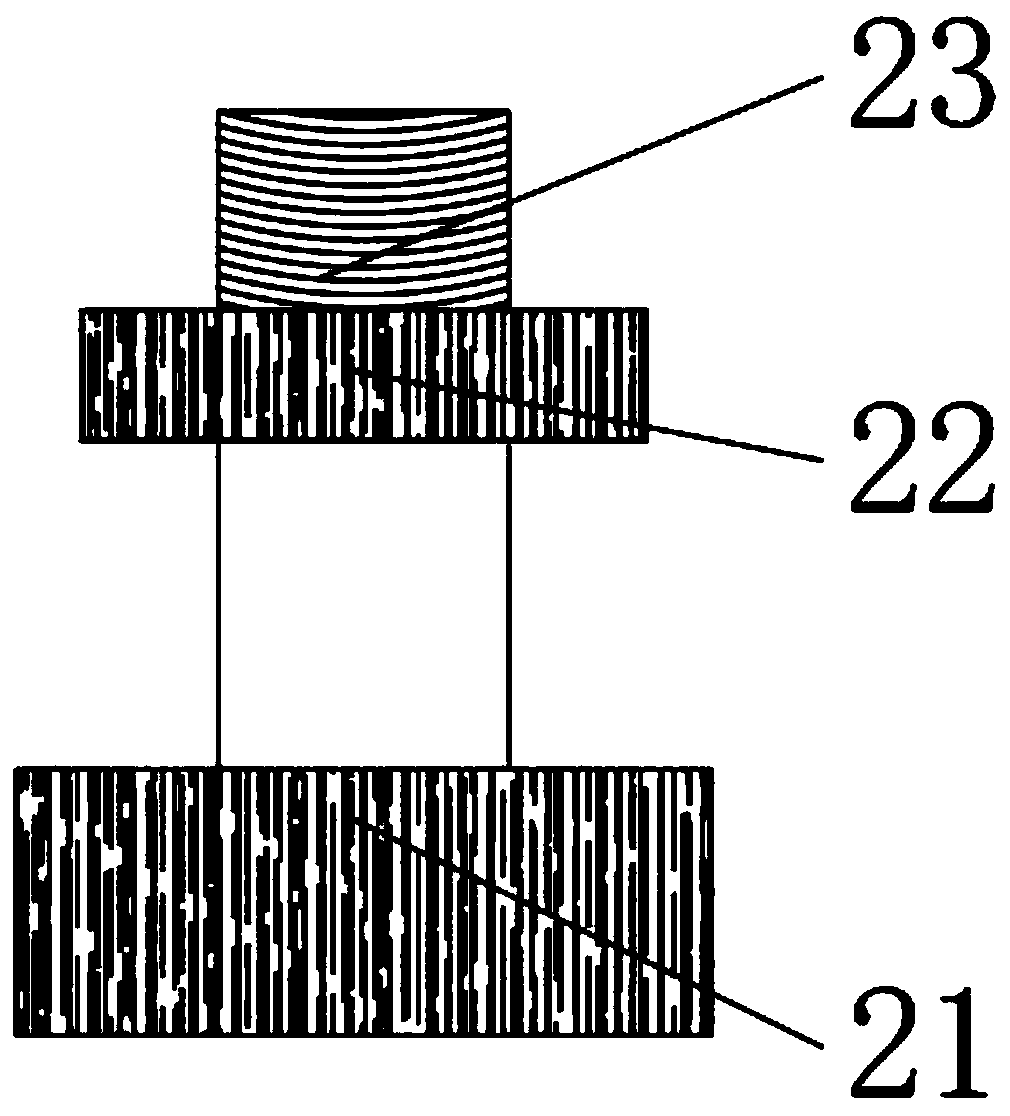

[0024] On the basis of Embodiment 1, such as figure 2 As shown, the stable adjustment structure 2 includes a support chassis 21, a fastening nut 22 and an adjustment half-threaded post 23. The lower outer surface of the smooth adjustment structure 2 is provided with a support chassis 21, and the upper end outer surface of the support chassis 21 is provided with an adjustment half-thread post. 23. The outer surface of the middle part of the adjustment half-thread column 23 is provided with a fastening nut 22. When the grinder is placed, it can be adjusted according to the flatness of the ground at the placement position by rotating the support chassis 21 to make the adjustment of the half-thread column 23 during centrifugal grinding. The bottom of the machine main body 1 protrudes or retracts, and then tightens it with the fastening nut 22 to ensure that the position of the adjusting half-threaded column 23 will not be loosened at will, and can ensure that the grinding machine ...

Embodiment 3

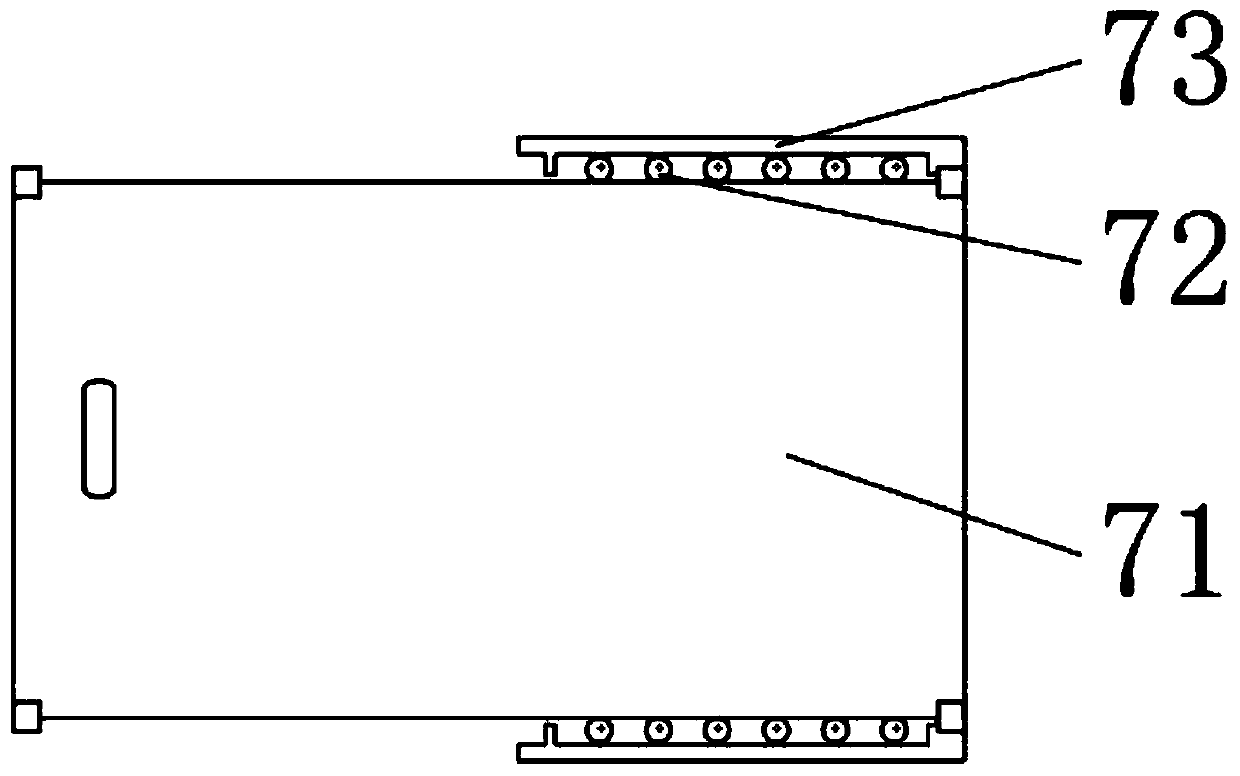

[0026] On the basis of embodiment one and embodiment two, such as image 3 As shown, the isolation observation structure 7 includes a tempered glass protection door 71, anti-jamming guide wheels 72 and limit slide rail blocks 73, the middle part of the isolation observation structure 7 is provided with a tempered glass protection door 71, and the upper end outer surface of the tempered glass protection door 71 An anti-jamming guide wheel 72 is provided, and the outer surface of the anti-jamming guiding wheel 72 is provided with a limit slide rail block 73. When the grinder grinds the workpiece, the tempered glass protective door 71 can be promoted, and the anti-jamming guiding wheel 72 guides Under the effect, under the limiting effect of the limiting slide rail block 73, the tempered glass protective door 71 is blocked in front of the grinding work area in the middle of the grinding tool chamber 5, which can prevent the internal debris from being ejected and facilitate people ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com