Fixing and clamping device for thermocouple

A technology for fixing clamping and fixing blocks, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of affecting the accuracy of temperature monitoring, inconvenient for staff to use, inconvenient for installation and replacement, etc. Convenience and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

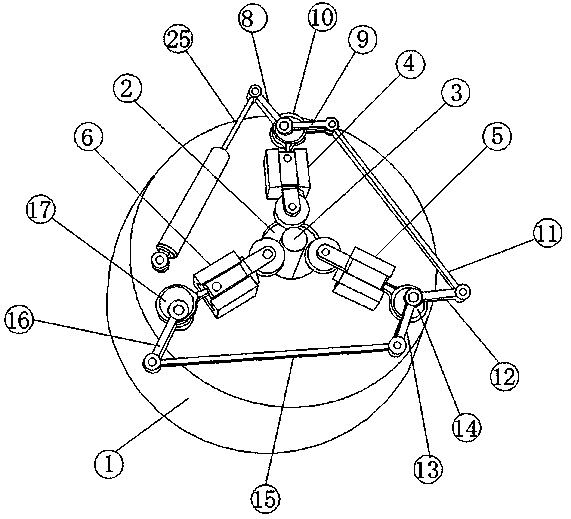

[0022] see Figure 1-2 According to an embodiment of the present invention, a fixing and clamping device for a thermocouple includes a fixing block 1, which can play a supporting role, and a through hole 2 is provided in the middle of the fixing block 1, and the through hole 2 is provided in the middle of the fixing block 1. The hole is a circular through hole. The through hole 2 can facilitate the placement of the thermocouple. The outer wall is tightened and fixed, and the periphery of the through hole 2 is located on the fixed block 1 and is respectively provided with a first mounting block 4, a second mounting block 5 and a third mounting block 6, the first mounting block 4, the second mounting block The block 5 and the third mounting block 6 are fixedly installed on the fixed block 1 at an angle of 120°, and are located around the through hole, which can facilitate the uniform force during extrusion. The first mounting block 4. Both the second mounting block 5 and the th...

Embodiment 2

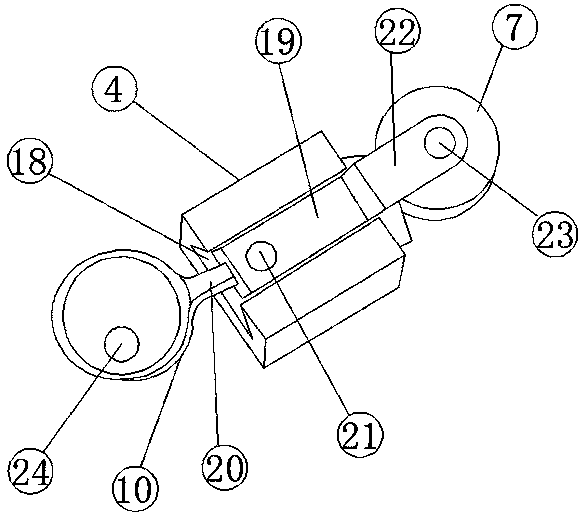

[0025] see figure 2 , for the sliding device, the sliding device includes a chute 18, the chute 18 is a bar-shaped chute 18, and the chute 18 is respectively provided with the first mounting block 4, the second mounting block 5 and the third mounting block. On the mounting block 6, the inside of the chute 18 is provided with a slide block 19, which matches between the chute 18 and the slide block 19, and one end of the slide block 19 is provided with a fixed rod 20, and the fixed rod is convenient for the slide block 19 In connection with the fixed rod 20 , the end of the slider 19 away from the fixed rod 20 is connected to the limit wheel 7 .

Embodiment 3

[0027] see figure 2 , for the fixed rod 20, the fixed rod 20 is respectively fixedly connected with one side of the first turntable 10, the second turntable 14 and the third turntable 17, and the connection between the fixed bar 20 and the slider 19 The movable pins 21 are movably connected to facilitate the movable connection between the fixed rod 20 and the slider 19, and facilitate the movement of the fixed rod 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com