Energy-saving type industrial robot and drive unit time-sharing control method thereof

A technology of industrial robots and drive units, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., and can solve problems such as energy loss, large mass of moving parts of robots, and large inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

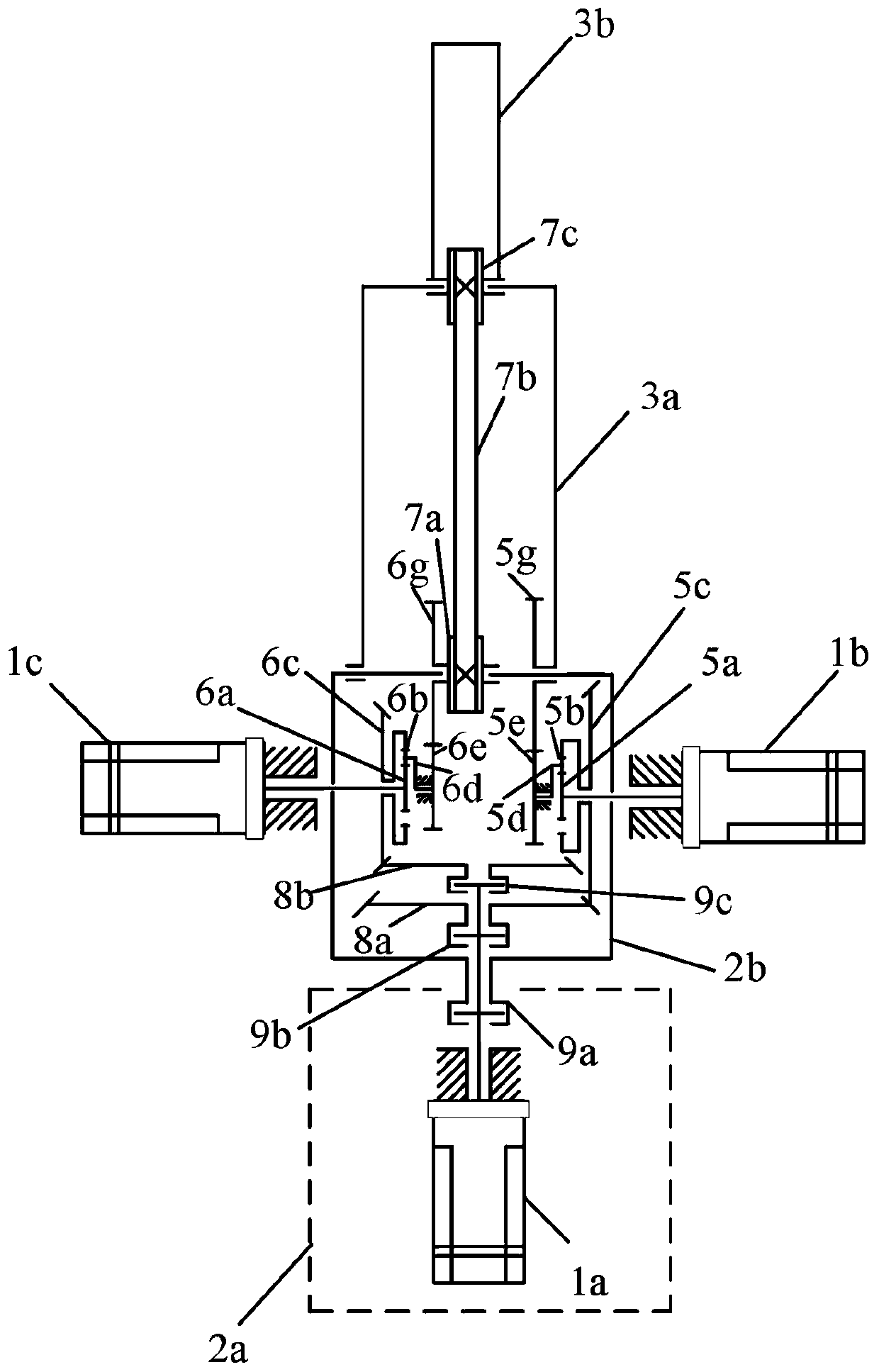

[0050] see figure 1 , an energy-saving industrial robot in this embodiment is provided with an arm base 2b on the base 2a, and is driven by the arm base drive unit 1a; a large arm 3a is provided at the top between the two clamping keys of the arm base 2b , and is driven synthetically by the arm seat drive unit 1a and the boom drive unit 1b through the first differential gear train;

[0051] The first differential gear train is composed of the first sun gear 5a, the first planetary gear 5b, the first ring gear 5c, and the first planet carrier 5d, and the first differential gear train is based on the first sun gear 5a and the first gear The ring 5c is the input end, and the first planet carrier 5d is the output end;

[0052] A small arm 3b is provided on the top of the large arm 3a, and is driven synthetically by the arm seat drive unit 1a and the small arm drive unit 1c through the second differential gear train;

[0053] The second differential gear train is composed of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com