Graphitic stationary ring for mechanical seal device and manufacturing method thereof

A technology of mechanical sealing device and manufacturing method, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., and can solve the problems of static ring fragmentation, waste of time for finished products, embrittlement and fragmentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

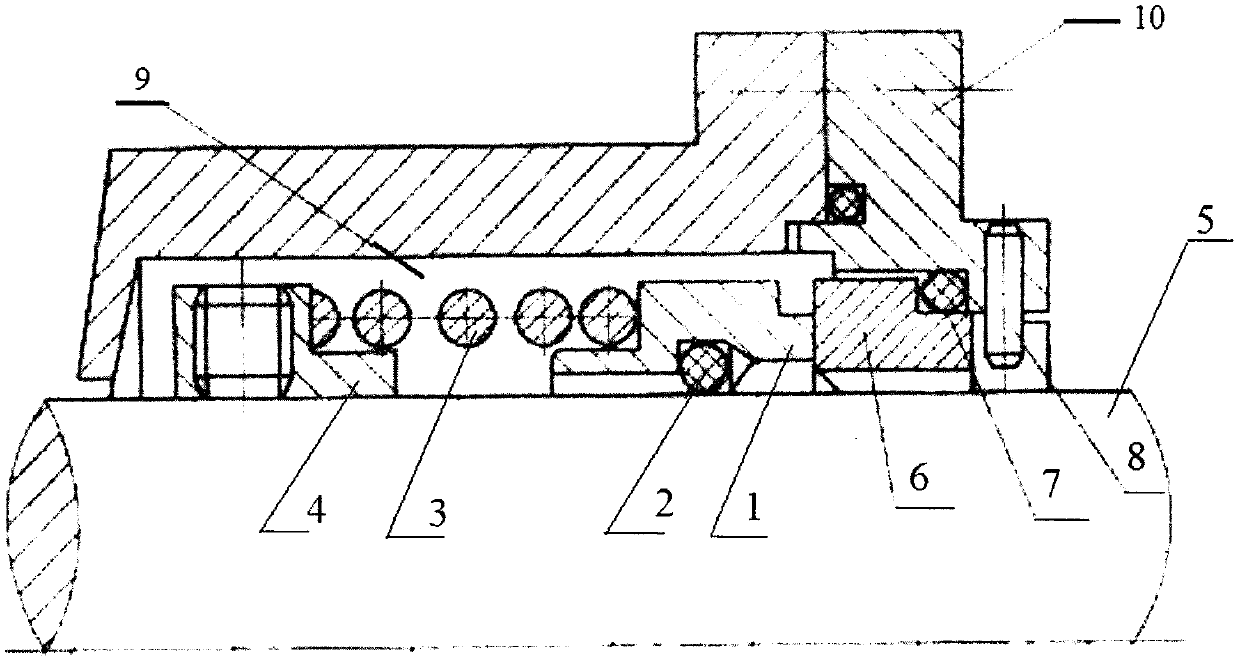

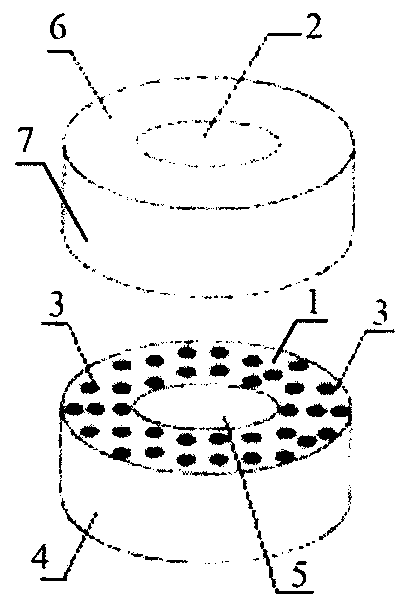

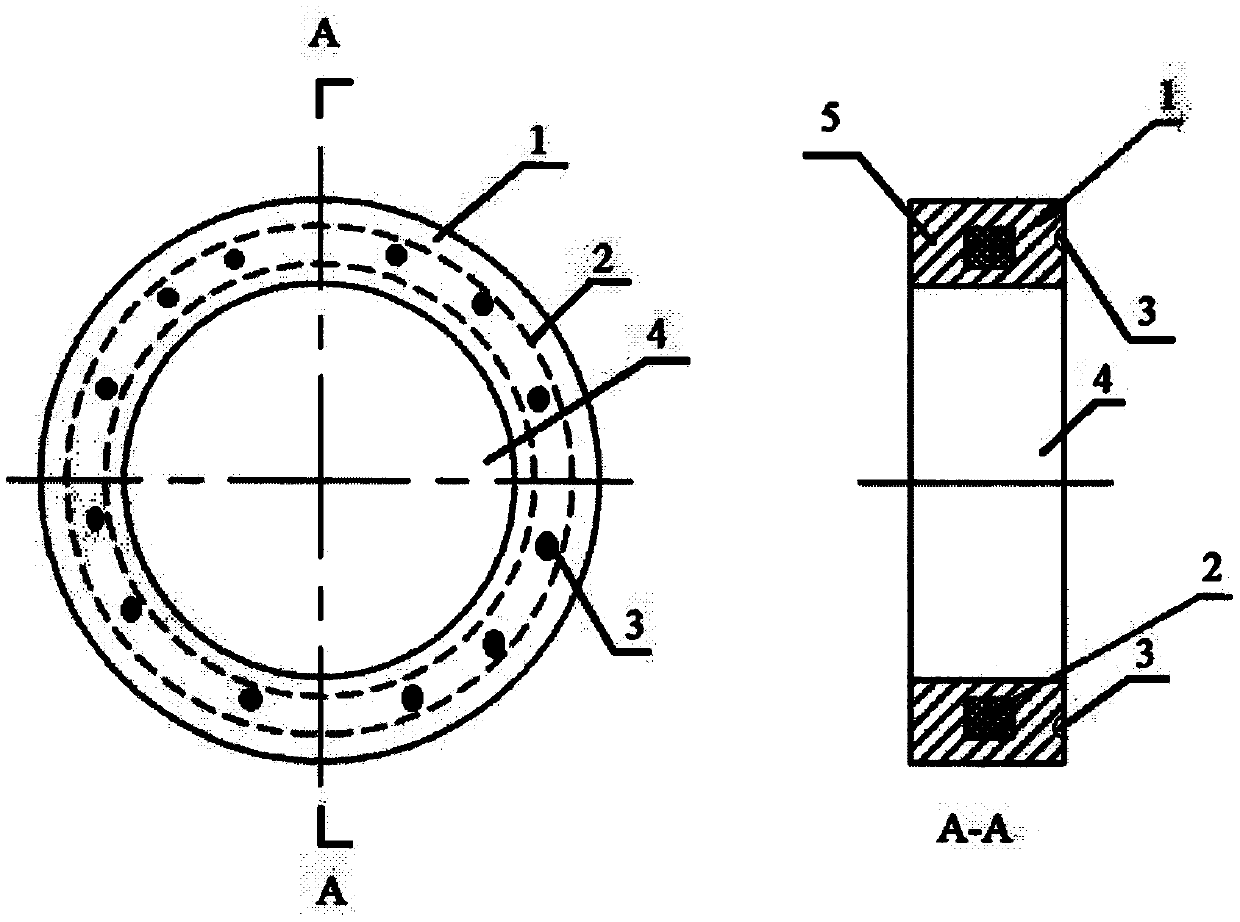

[0011] Embodiment: Manufacturing process flow of a graphite stationary ring for a mechanical seal device with an outer diameter of 80 mm, an inner diameter of 20 mm, and a thickness of 10 mm. First adopt the machining method to produce the square cross-section iron-nickel alloy ring, its size specification is: outer diameter 60mm, inner diameter 50mm, thickness 4mm, spare; take a proper amount of nylon 202 sealant, take a proper amount of flexible graphite, and Mix the two evenly and put them in the ring mold. At the same time, put the spare square-section iron-nickel alloy ring in the mixed graphite. At this time, you must pay attention to the operation of putting the iron-nickel alloy ring in the mixing The central part of a good graphite material; then, put the mold in an oven and bake it at 80°C for 15 minutes; then take it out and press it into a ring-shaped graphite stationary ring blank under a pressure of 100Mpa; Put the graphite static ring blank in the oven and bake ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com