Remote control method and system for smart tea bag packaging machine

A remote control system and remote control technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of inability to monitor the operation performance of vulnerable parts of equipment in real time, increase equipment downtime, and high maintenance costs. To achieve the effect of remote monitoring and predictive maintenance, improve timeliness and efficiency, and realize remote alarm management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

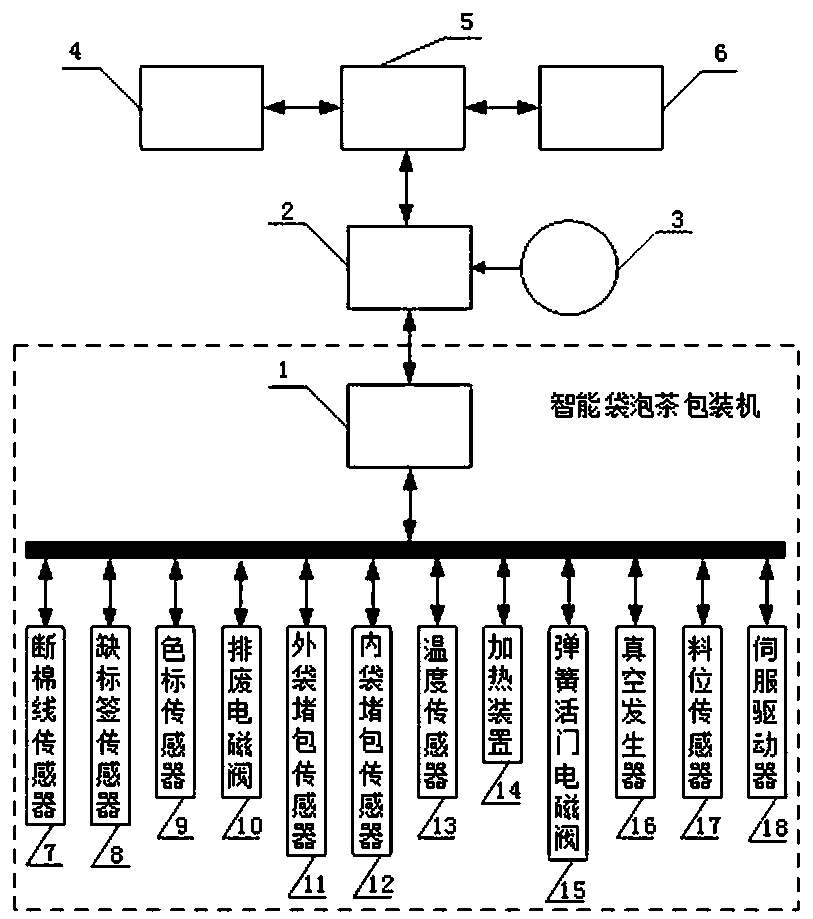

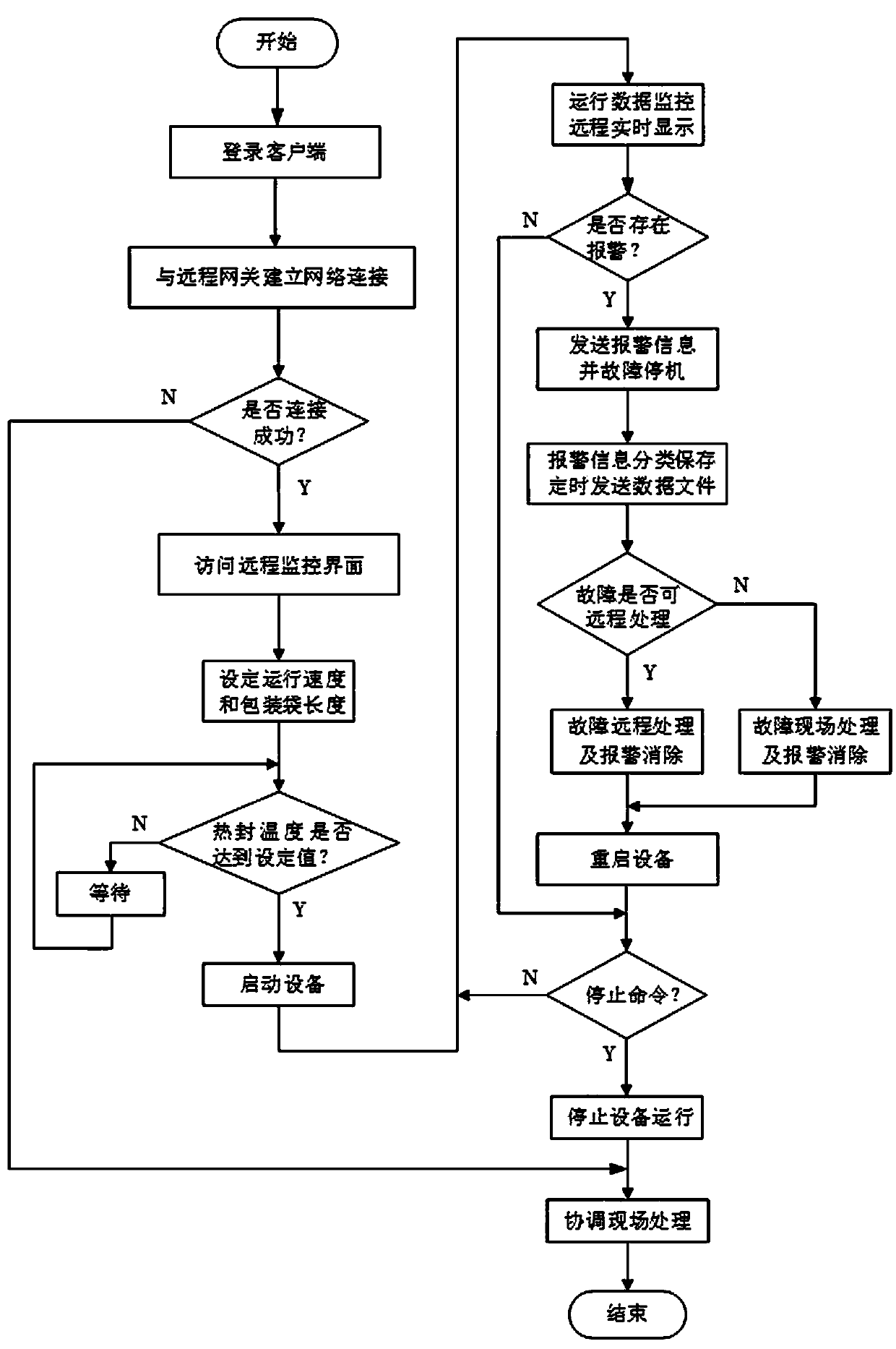

[0026] In order to realize the remote monitoring of the intelligent teabag packaging machine equipment, the PLC controller 1 and the IP cloud camera 3 are respectively connected to the industrial remote gateway 2 to establish a data connection, and the industrial remote gateway 2 establishes network communication with the cloud server 5 through a wired network, For real-time data transmission, remote control terminals such as industrial computers 4 and mobile phones 6 access the cloud server 5 through the login authority account, and then establish a remote data connection with the on-site industrial remote gateway 2, so that the remote control terminal can access the on-site PLC controller in real time 1 and IP cloud camera 3. details as follows.

[0027] First, connect the industrial com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com