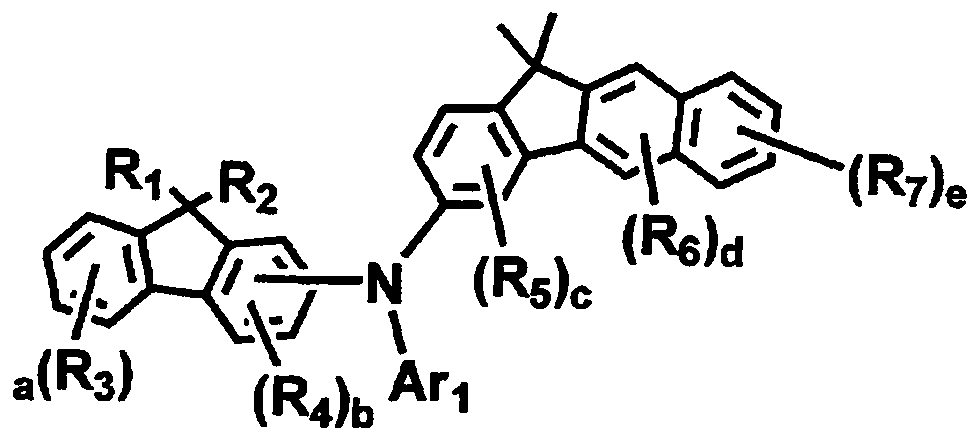

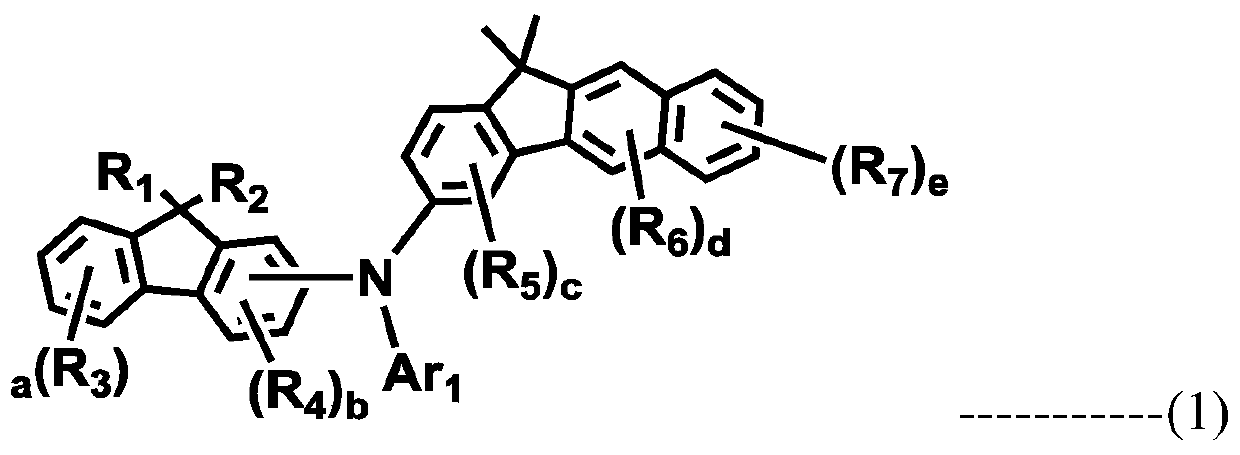

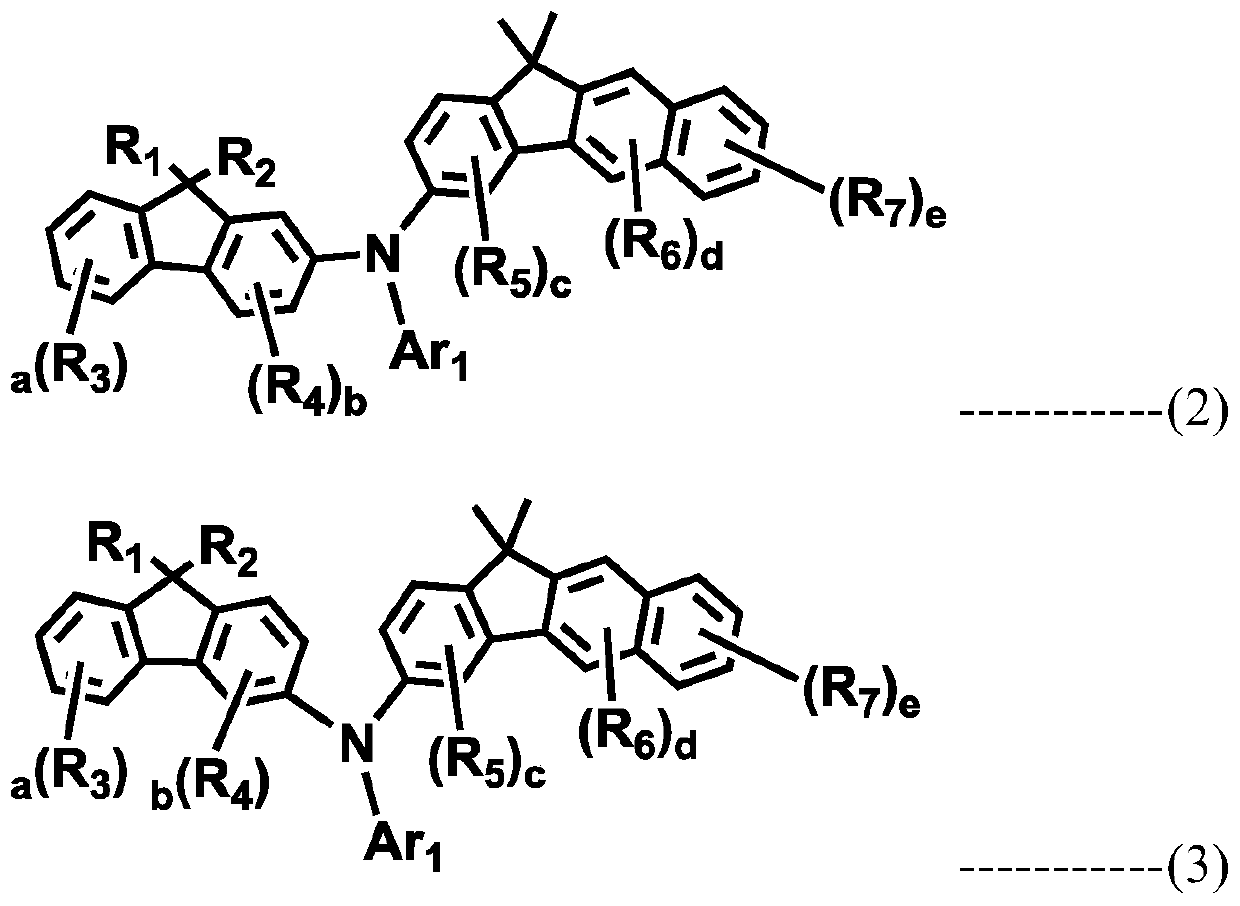

Organic electroluminescent compound and organic electroluminescent device comprising the same

A luminescent and compound technology, applied in the field of organic electroluminescent compounds, can solve the problems of reduced quantum efficiency, reduced device service life, quantum efficiency and service life deterioration, and achieves high luminous efficiency, long service life, and low drive. The effect of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0091] Example 1: Preparation of Compound C-4

[0092]

[0093] 10g of compound a-1 (31mmol), 11.2g of compound b-1 (31mmol), 1.42g of three (dibenzylideneacetone) dipalladium (0) (1.6mmol), 1.6mL of tri-tert-butyl Phosphine (3.1 mmol, 50% solution in toluene), 5.9 g of sodium tert-butoxide (62 mmol), and 154 mL of toluene were introduced into the reaction vessel, and the mixture was refluxed for 4 hours. The reaction solution was cooled to room temperature, and then the solvent was removed by a rotary evaporator. The residue was purified by column chromatography to obtain 8.3 g of Compound C-4 (yield: 44%).

example 2

[0094] Example 2: Preparation of Compound C-5

[0095]

[0096] 7.0g of compound a-1 (22mmol), 8.6g of compound b-2 (24mmol), 0.60g of three (dibenzylideneacetone) dipalladium (0) (0.66mmol), 0.6mL of tri-tert-butyl Phosphine (1.32 mmol, 50% solution in toluene), 3.1 g of sodium tert-butoxide (32 mmol), and 110 mL of toluene were introduced into the reaction vessel, and the mixture was refluxed for 2 hours. The reaction solution was cooled to room temperature, and then the solvent was removed by a rotary evaporator. The residue was purified by column chromatography to obtain 0.9 g of Compound C-5 (yield: 7%).

example 3

[0097] Example 3: Preparation of Compound C-6

[0098]

[0099] 7.4g of compound a-1 (23mmol), 10.0g of compound b-3 (23mmol), 1.0g of three (dibenzylideneacetone) dipalladium (0) (1.2mmol), 1.1mL of tri-tert-butyl Phosphine (2.3 mmol, 50% solution in toluene), 4.4 g of sodium tert-butoxide (46 mmol), and 114 mL of toluene were introduced into the reaction vessel, and the mixture was refluxed for 5 hours. The reaction solution was cooled to room temperature, and then the solvent was removed by a rotary evaporator. The residue was purified by column chromatography to obtain 4.9 g of Compound C-6 (yield: 31%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com