Partial Sandblasting Method for Parts

A technology of parts and sand blasting, which is applied in the direction of abrasive jet machine tools, used abrasive processing devices, metal processing equipment, etc., can solve the problems affecting the flatness of parts, the surface of easy-wear parts, and the escape of sand particles, etc., to achieve time-consuming solutions Effortless, constant flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

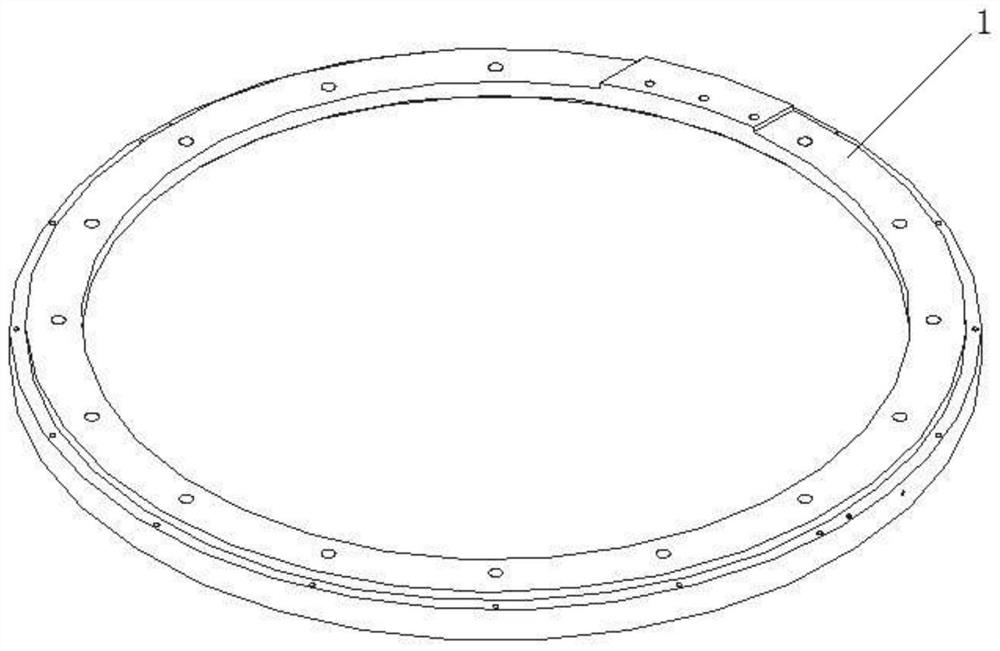

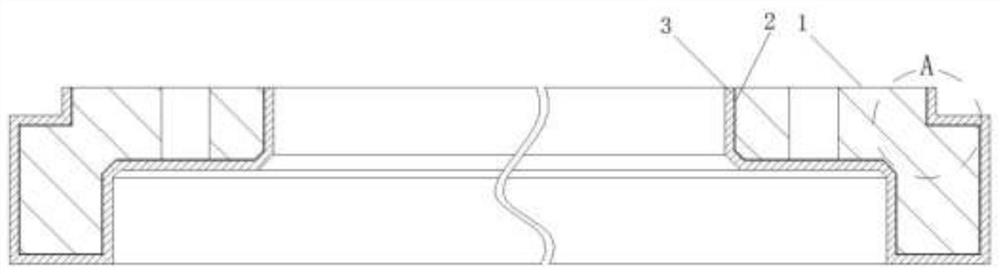

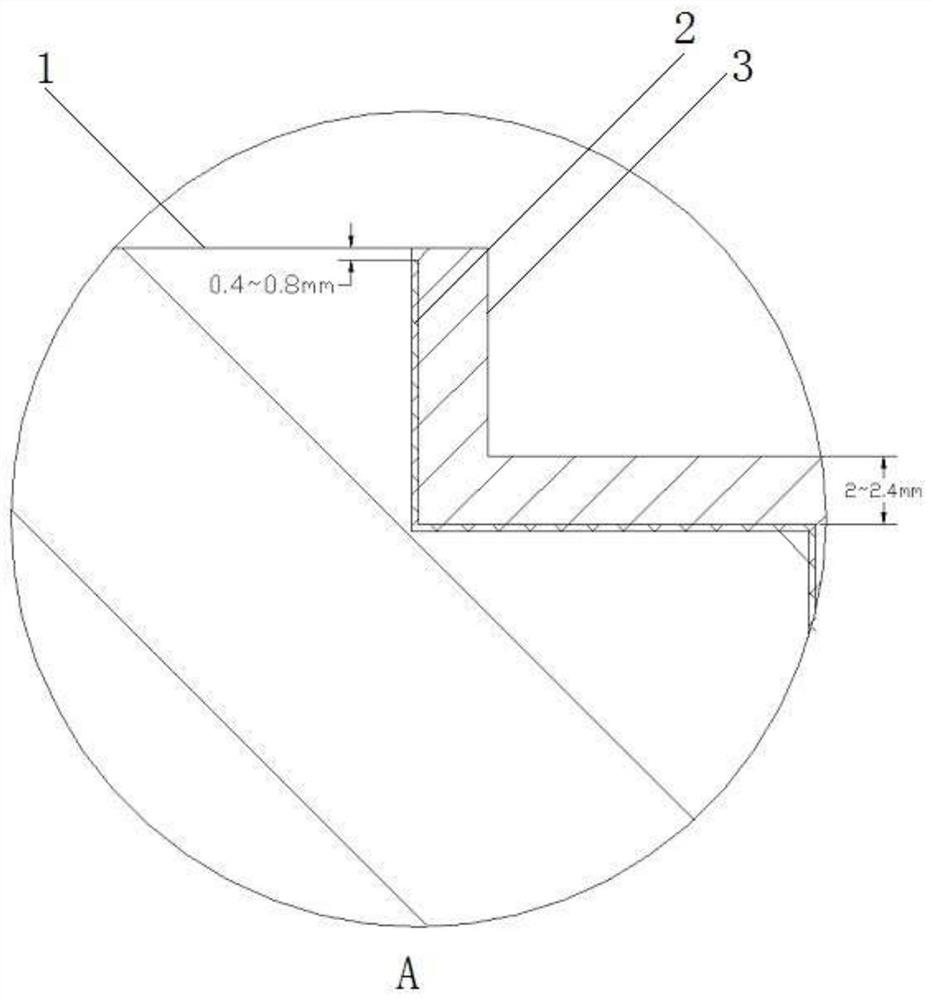

[0022] see figure 1 , figure 2 , image 3 , Figure 4 shown.

[0023] A local sandblasting method of a part of the present invention comprises steps as follows:

[0024] Step 1: Paste the detachable layer 2 on the part of the part 1 that does not need to be sandblasted;

[0025] Step 2: apply curing layer 3 on the outside of disassembly layer 2;

[0026] Step 3: Apply the cured layer 3 to dry and cure in natural air.

[0027] After the solidified layer 3 is cured, under the force of the solidified layer 3, the detachable layer 2 is in close contact with the part 1, and then sandblasting is performed. The strength of the solidified layer 3 protects the parts of the part 1 that do not need sandblasting; After the sandblasting is completed, the disassembly and assembly of the disassembly layer 2 directly drives the curing laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com