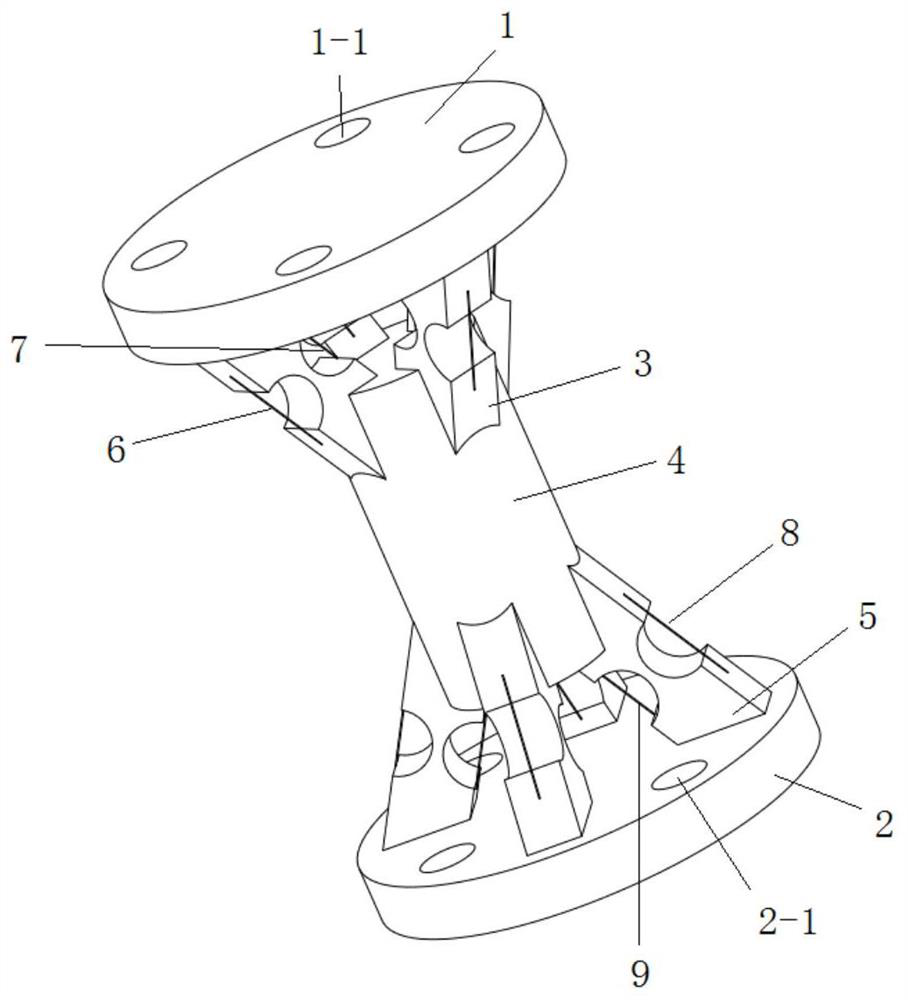

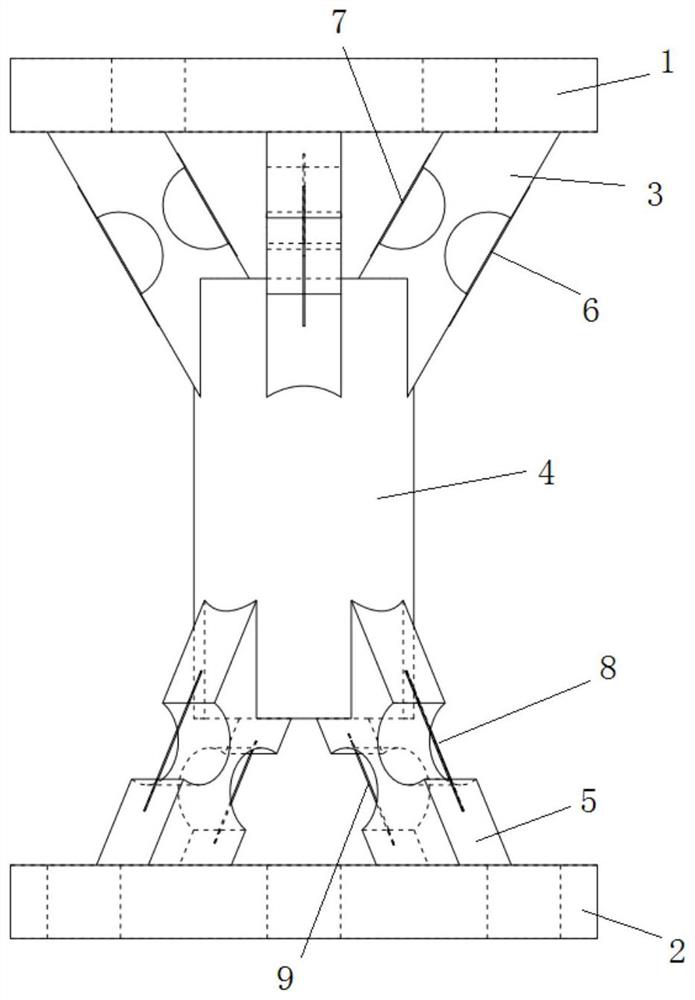

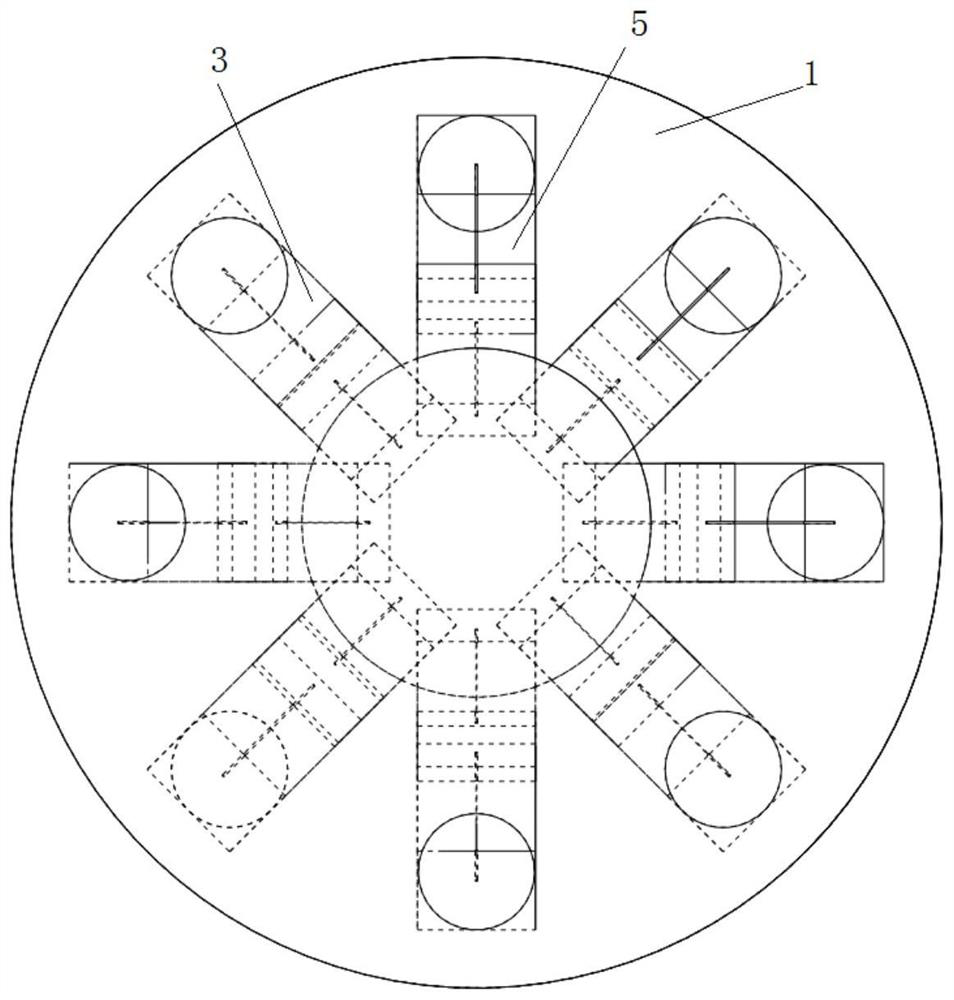

A sensing device for a mechanical arm, a mechanical arm assembly and application thereof

A sensing device and a robotic arm technology, applied in the field of robotic arms, can solve the problem of low calculation accuracy of force and torque, and achieve the effects of strong applicability, accurate calculation results, and accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0044] This embodiment discloses a mechanical arm assembly, including a mechanical arm, a clamping mechanism, and the sensing device for the mechanical arm. The end of the mechanical arm is fixedly connected to the second connecting plate through the second mounting hole. A connection plate is connected with the clamping mechanism through the first installation hole, the existing mechanical arm can be used as the described mechanical arm, and its specific structure will not be described in detail here, and the existing mechanical arm clamp is used for the described clamping mechanism. Only one clamping mechanism is sufficient, and those skilled in the art can select different types of clamping mechanisms according to actual needs, and the specific structure thereof will not be described in detail here.

Embodiment 3

[0046] This embodiment discloses a production line equipped with at least one mechanical arm assembly described in Embodiment 2 for production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com