Environment-friendly carborundum wire cutting fluid

A technology of emery wire and cutting fluid, applied in the petroleum industry, lubricating composition and other directions, can solve the problems of affecting the photoelectric conversion efficiency of solar cells, reducing the storage stability of cutting fluid, and decreasing the smoothness of products, etc. Improve production efficiency and economic benefits, improve the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

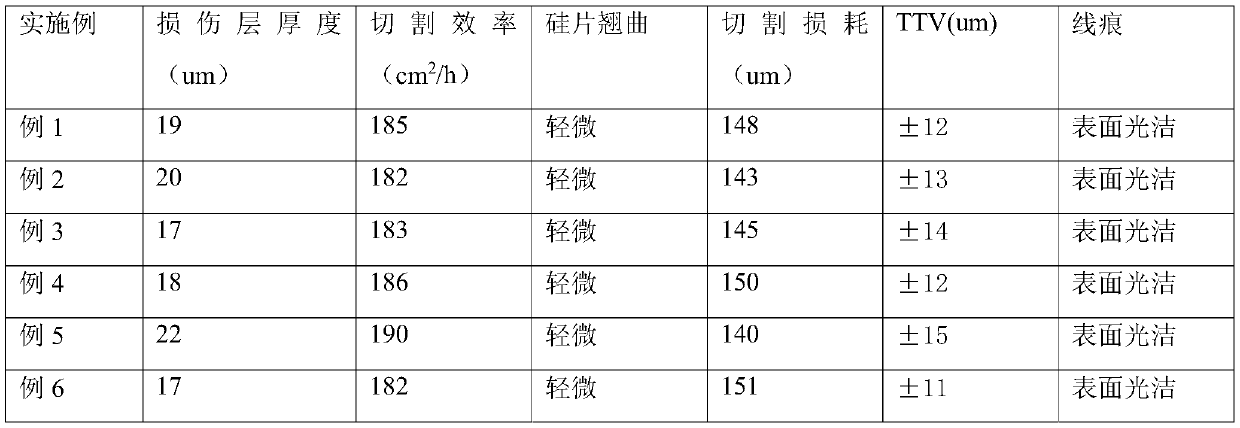

Examples

Embodiment 1

[0017] The environment-friendly emery wire-cutting fluid of the present embodiment, the wire-cutting fluid raw material comprises the following components by weight percentage: polybranched alcohol modified surfactant 3%, dodecynediol polyoxyethylene ether 3%, hyperbranched 0.5% of Gemini cationic surfactant, 5% of special alcohol ether, 3% of isomeric stearic acid, 3% of AMP-95, and the balance is added to 100% by deionized water.

Embodiment 2

[0019] The environment-friendly emery wire-cutting fluid of the present embodiment, the wire-cutting fluid raw material comprises the following components by weight percentage: polybranched alcohol modified surfactant 5%, dodecynediol polyoxyethylene ether 5%, hyperbranched 1% of Gemini cationic surfactant, 15% of special alcohol ether, 5% of isomeric stearic acid, 5% of AMP-95, and the balance is added to 100% by deionized water.

Embodiment 3

[0021] The environment-friendly emery wire-cutting fluid of the present embodiment, the wire-cutting fluid raw material comprises the following components by weight percentage: polybranched alcohol modified surfactant 3%, dodecynediol polyoxyethylene ether 5%, hyperbranched 0.5% of Gemini cationic surfactant, 15% of special alcohol ether, 3% of isomeric stearic acid, AMP-955%, and the balance is deionized water to 100%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap