Weft-knitted fabric with multilayer structure and knitting method thereof

A multi-layer structure and knitted fabric technology, which is applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of weft-knitted sandwich fabrics, such as insufficient fineness and smoothness, and easy bottom leakage, etc., and achieve thick and smooth hand feeling and good extension Sexuality and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Selection of raw materials:

[0035] Choose polyester yarn and cotton yarn for weaving. Among them, the connecting wire of the interval layer is woven with 75D polyester yarn, the small formation coil is woven with 30D polyester yarn, and the fabric surface coil is woven with 40S cotton yarn.

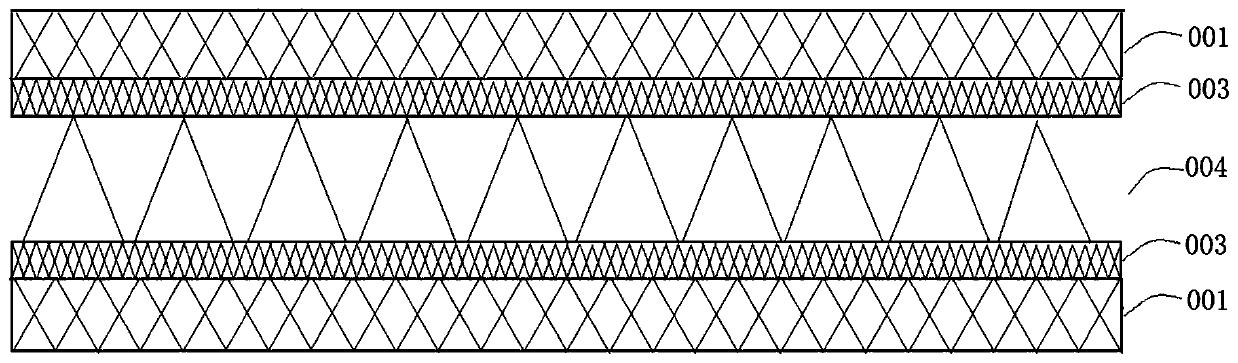

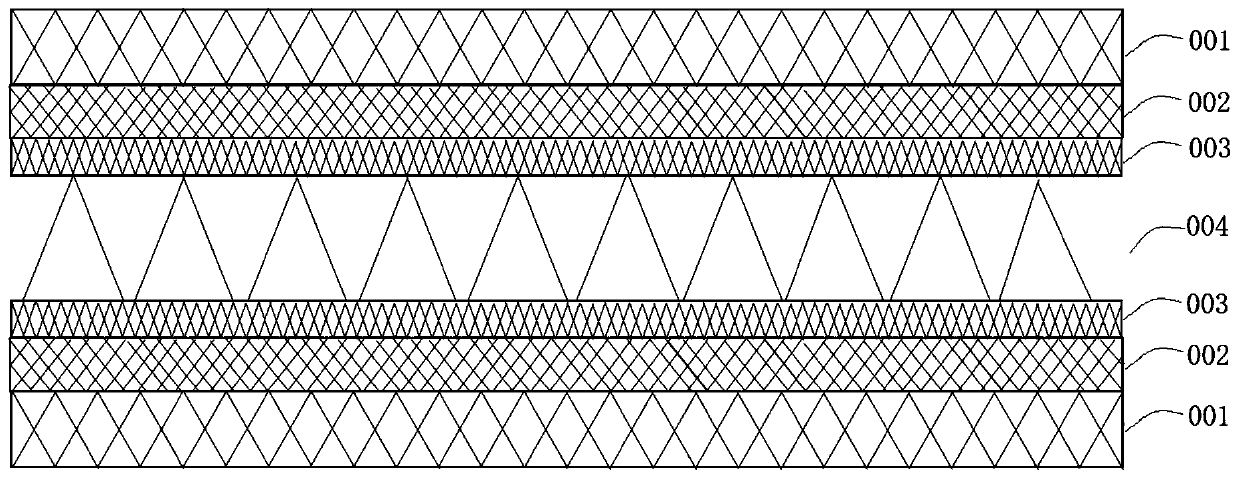

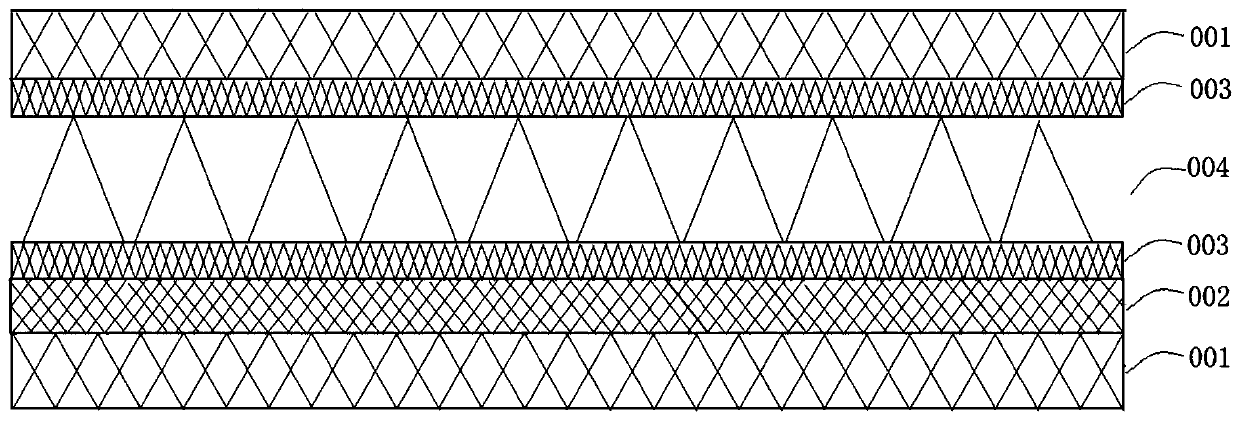

[0036] (2) Weaving and yarn arrangement process:

[0037] Such as Figure 4 , as shown in 5 and 6, the weaving principle is mainly that the stratum coil does not take off the loop after it is looped, and forms the same row with the surface coil synchronously. Weaving is carried out on a modified weft knitting double-sided circular weft machine, and a six-way loop forming system is used to weave a coil course; according to Figure 5 The knitting needles are arranged in a triangle for movement. The 1st and 2nd knitting tucks are used as connecting yarns, and the 3rd and 4th knitting needles are all knitted to form a loop. The 3rd knitting formation loop does not take off th...

Embodiment 2

[0041] (1) Selection of raw materials

[0042] Choose polyester yarn, cotton yarn, spandex for weaving. Among them, the connecting wire is woven with 75D polyester yarn, the small coil is woven with 30D polyester yarn, and the fabric surface coil is woven with 40S cotton yarn and 20D spandex.

[0043] (2) Weaving and yarn arrangement process

[0044] Such as Figure 4 , as shown in 5 and 6, the weaving principle is mainly that the stratum coil does not take off the loop after it is looped, and forms the same row with the surface coil synchronously. Weaving is carried out on the modified weft knitting double-sided circular weft machine, and the six-way knitting system weaves a coil course, according to Figure 5 The knitting needles are arranged in a triangle for movement. The 1st and 2nd knitting tucks are used as connecting yarns, and the 3rd and 4th knitting needles are all knitted to form a loop. The 3rd knitting formation loop does not take off the loop. When the 4th k...

Embodiment 3

[0048] (1) Selection of raw materials

[0049]Choose polyester yarn, cotton yarn, spandex for weaving. Among them, the connecting wire is woven with 75D polyester yarn, the small coil is woven with 30D polyester yarn, and the fabric surface coil is woven with 40S cotton yarn and 20D spandex.

[0050] (2) Weaving and yarn arrangement process

[0051] Such as Figure 4 , as shown in 5 and 6, the weaving principle is mainly that the stratum coil does not take off the loop after it is looped, and forms the same row with the surface coil synchronously. Weaving is carried out on a modified weft knitting double-sided circular weft machine, and a six-way loop forming system is used to weave a coil course; according to Figure 5 The knitting needles are arranged in a triangle for movement. The 1st and 2nd knitting tucks are used as connecting yarns, and the 3rd and 4th knitting needles are all knitted to form a loop. The 3rd knitting formation loop does not take off the loop. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com