Synchronous construction integral steel platform formwork device and construction method

A technology of synchronous construction and construction methods, which is applied to the scaffolding supported by the building structure, the accessories of the scaffolding, and the processing of building materials, etc., can solve the problem of complex construction procedures, great influence on the mechanical performance of the structure, and the inability of the vertical structure and the horizontal structure. One-time construction molding and other issues to achieve the effect of ensuring the mechanical performance of the structure, avoiding construction quality problems and hidden safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

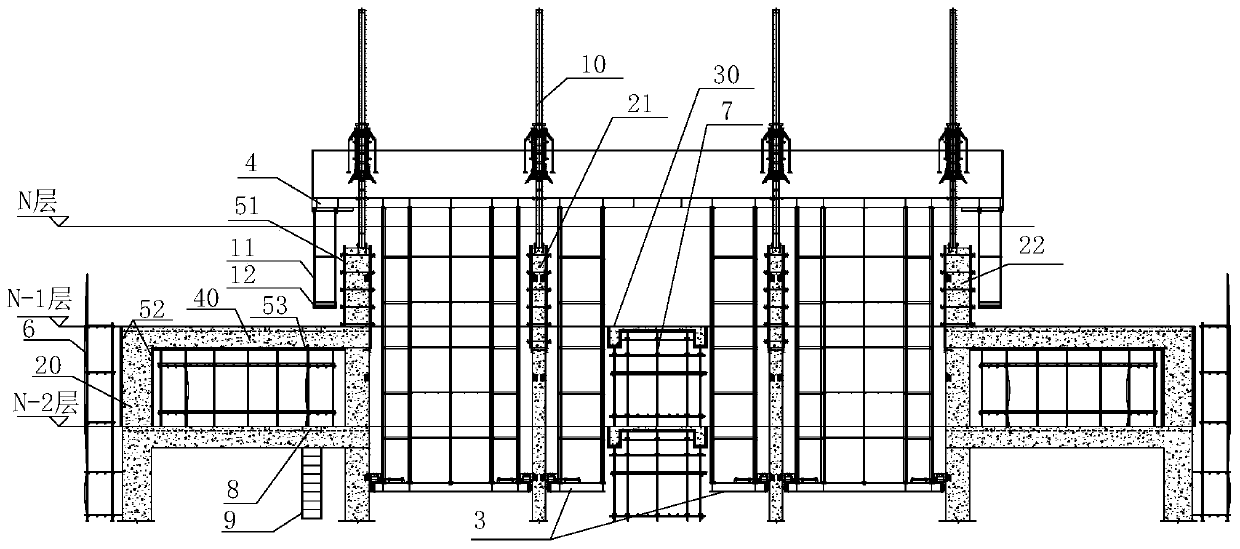

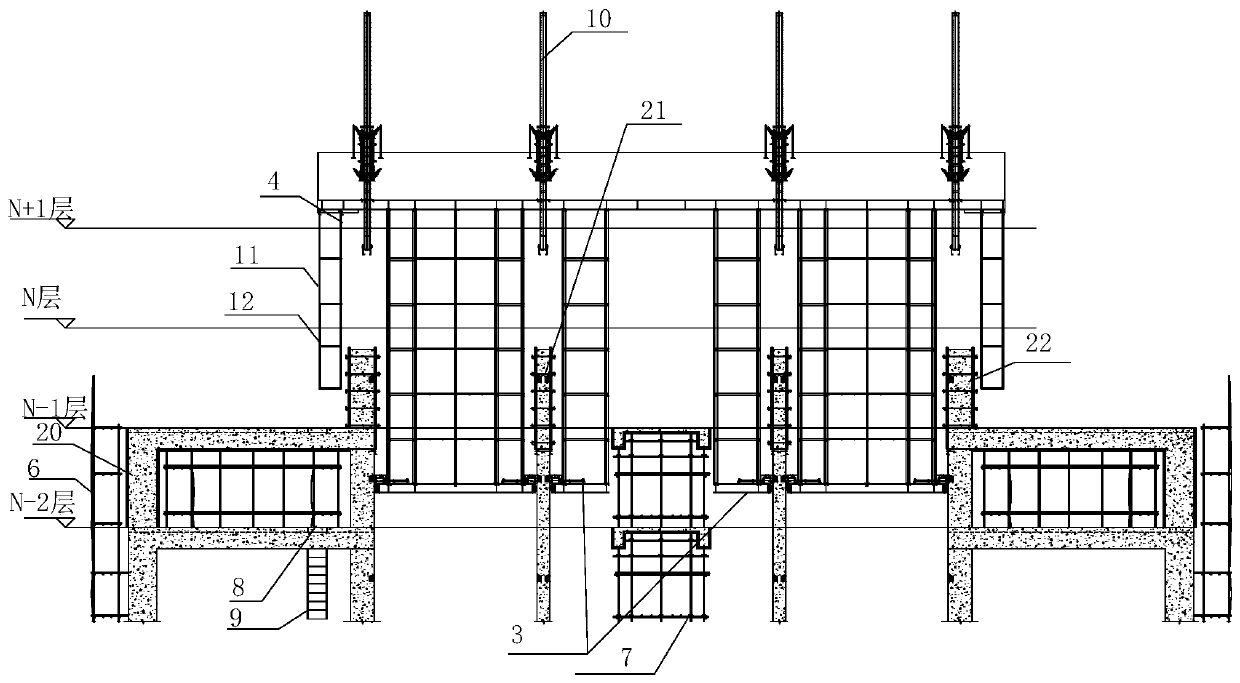

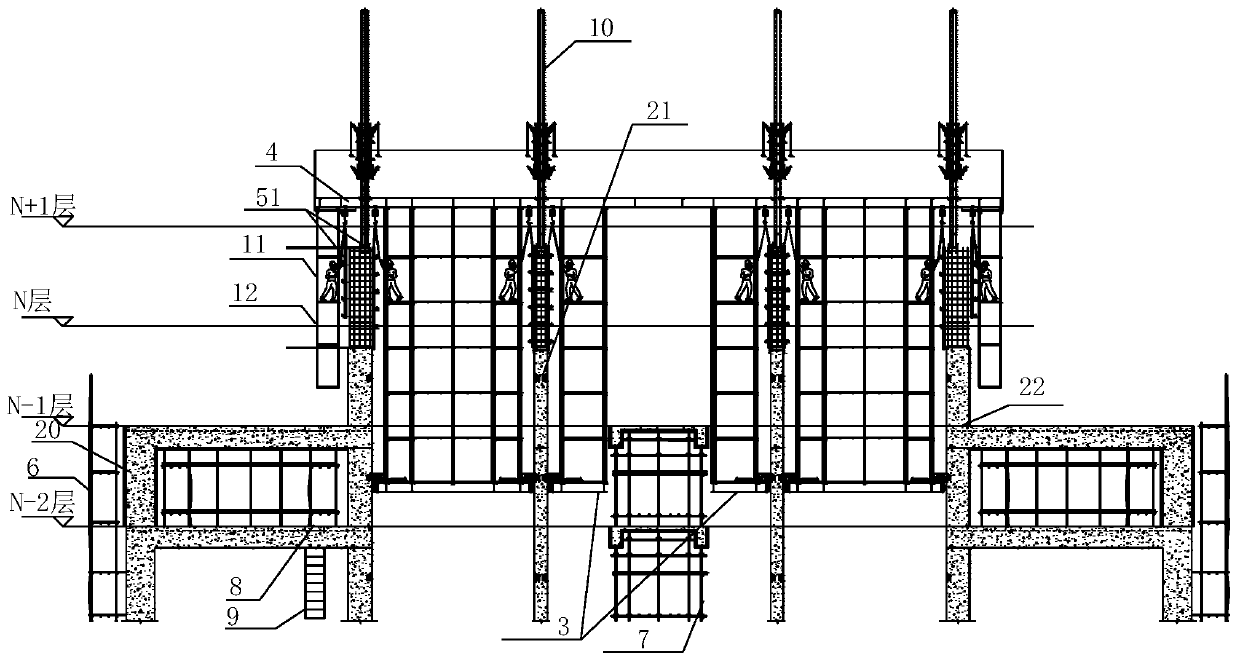

[0032] Combine below figure 1 The structural composition of the integral steel platform formwork for simultaneous construction of the present invention is described in detail.

[0033] Please refer to figure 1 , an integral steel platform formwork equipment for synchronous construction, including an integral steel platform and formwork; the integral steel platform includes a support system, a lifting system, external scaffolding and a steel platform, and the support system includes multiple standard columns and the first Column connection unit, the first column connection unit is connected between two adjacent standard columns, and the bottom of each standard column is fixed on the inner side of the formed core wall through wall corbels; the lifting system is set On the top of the support system, it is used to lift the steel platform formwork as a whole; the external scaffolding is set on the outside of the formed core tube wall, and the top of each external scaffolding is co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap