Direct-acting electromagnetic one-way valve

A direct-acting, one-way valve technology, applied in valve details, control valves, valve devices, etc., can solve the problems of oil reverse flow pressure loss, high geometric tolerance requirements, and long valve core response time. Achieve the effect of low processing cost, strong anti-pollution ability and reliable reverse sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

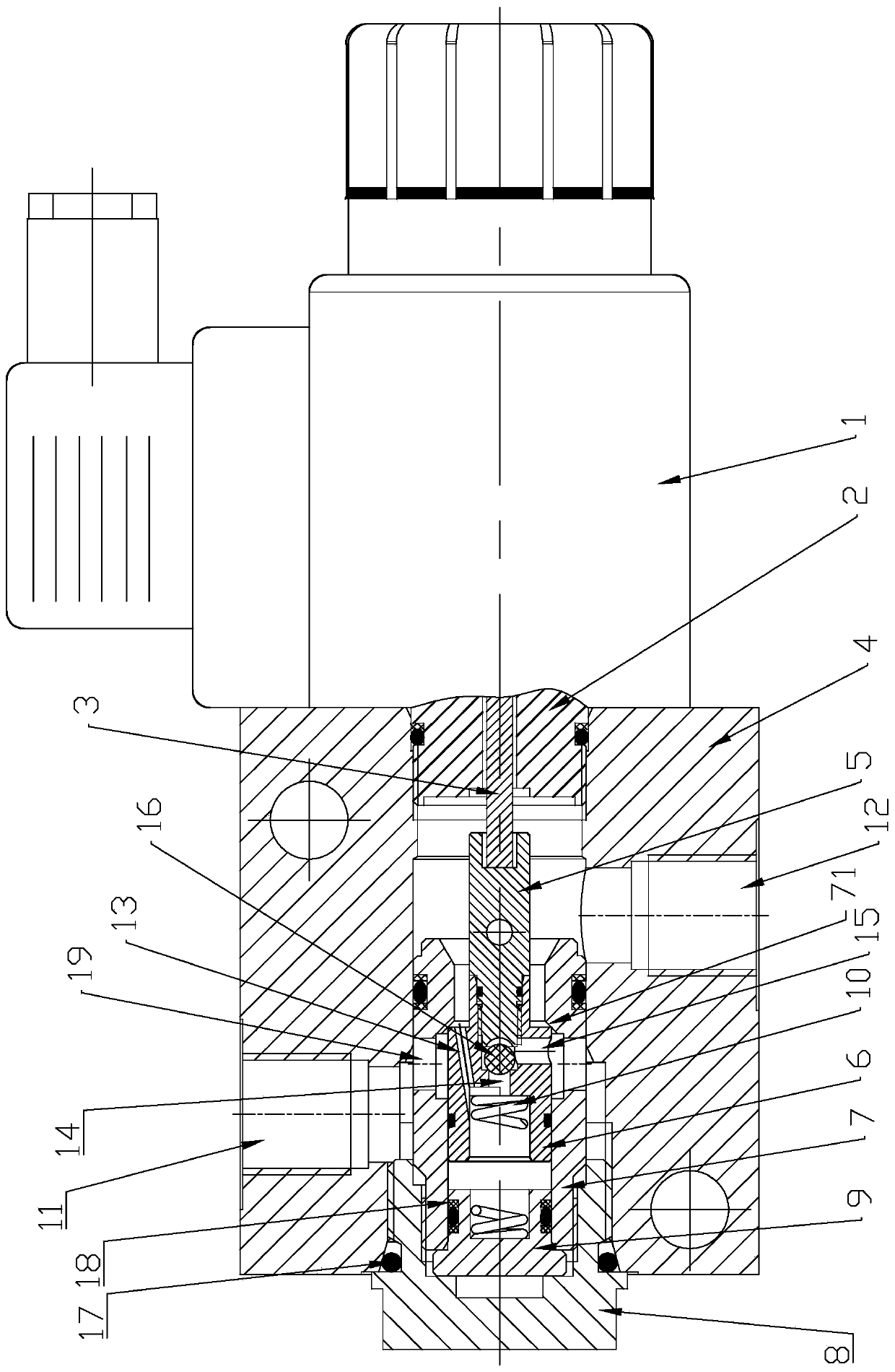

[0015] Refer to the attached figure 1 The direct acting electromagnetic check valve of the present invention will be described in detail below.

[0016] The direct-acting electromagnetic one-way valve of the present invention has a structure comprising an electromagnet coil 1, an electromagnet middle sleeve 2, an electromagnet push rod 3, a valve body 4, a transition push rod 5, a steel ball 16, a valve core 6, and a valve sleeve 7. End plug 8 and valve sleeve gland 9, the valve body 4 is arranged on the left side of the electromagnet coil 1, and the main hole of the valve body 4 is provided with end plug 8, valve sleeve 7 and The middle sleeve 2 of the electromagnet, the valve sleeve gland 9 is arranged between the end plug 8 and the valve sleeve 7, the valve core 6 is arranged in the valve sleeve 7, and the cavity between the valve core 6 and the valve sleeve gland 9 A return spring 10 is arranged inside, the valve body 4 is provided with an upper oil port 11 and a lower oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com