Liquid separator and compressor

A liquid separator and compressor technology, which is used in machines/engines, liquid variable capacity machines, refrigerators, etc. The overall vibration of the machine is increased, and the volumetric efficiency is stable, the pressure drop difference is guaranteed, and the energy efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the purpose, structure and function of the present invention, a liquid separator and a compressor of the present invention will be further described in detail below in conjunction with the accompanying drawings.

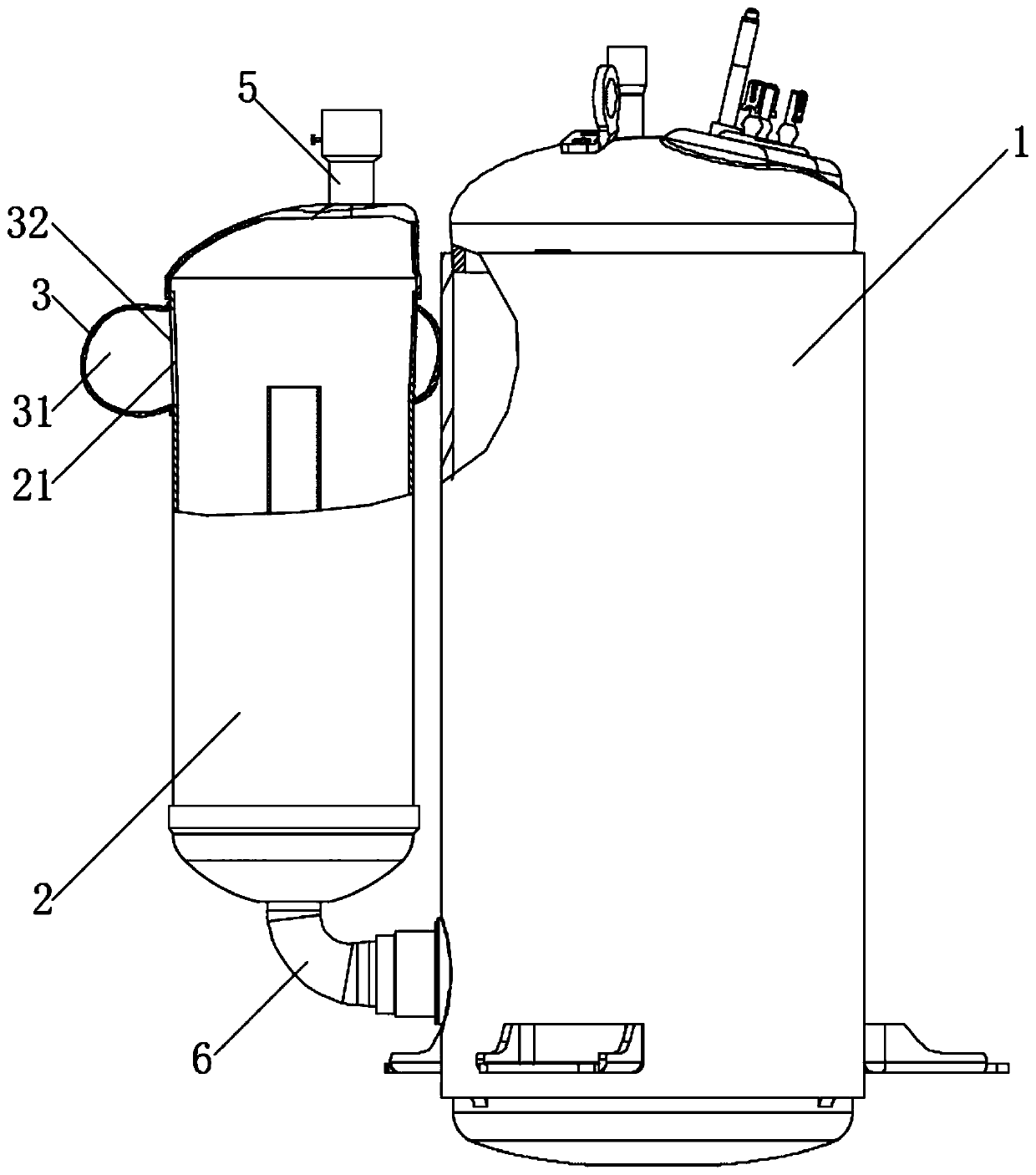

[0027] Such as figure 1 As shown, the compressor of the present invention includes a compressor body 1 and a liquid separator communicated with each other. The air outlet pipe 6 of the liquid separator is installed on the suction port of the compressor body 1, thereby connecting the liquid separator and the compressor body 1 and fixing them to each other.

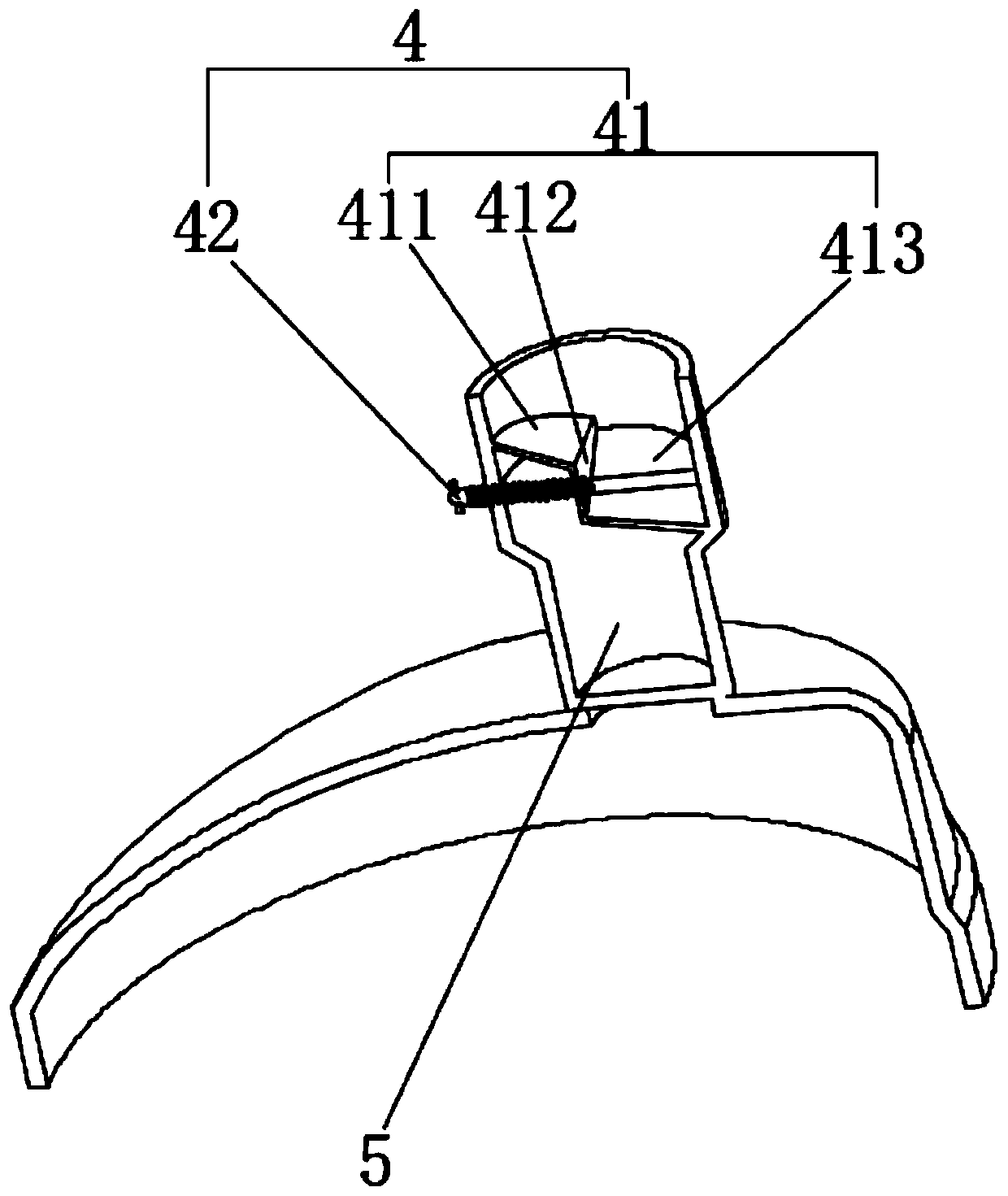

[0028] In order to stabilize the suction and exhaust pressure, the liquid distributor includes a cylinder body 2 and an elastic tube 3 . The expansion-contraction chamber 31 is formed in the elastic tube 3, and the expansion-contraction cavity 31 and the inner cavity of the cylinder body 2 are connected to each other, so that when the pressure in the cylinder body 2 changes, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com