Axial compensation mechanism for improving volume efficiency of sea water pump and sea water pump

A volumetric efficiency and axial compensation technology, applied to pumps, pump components, mechanical equipment, etc., can solve problems such as leakage, reduced work performance, and impact on volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

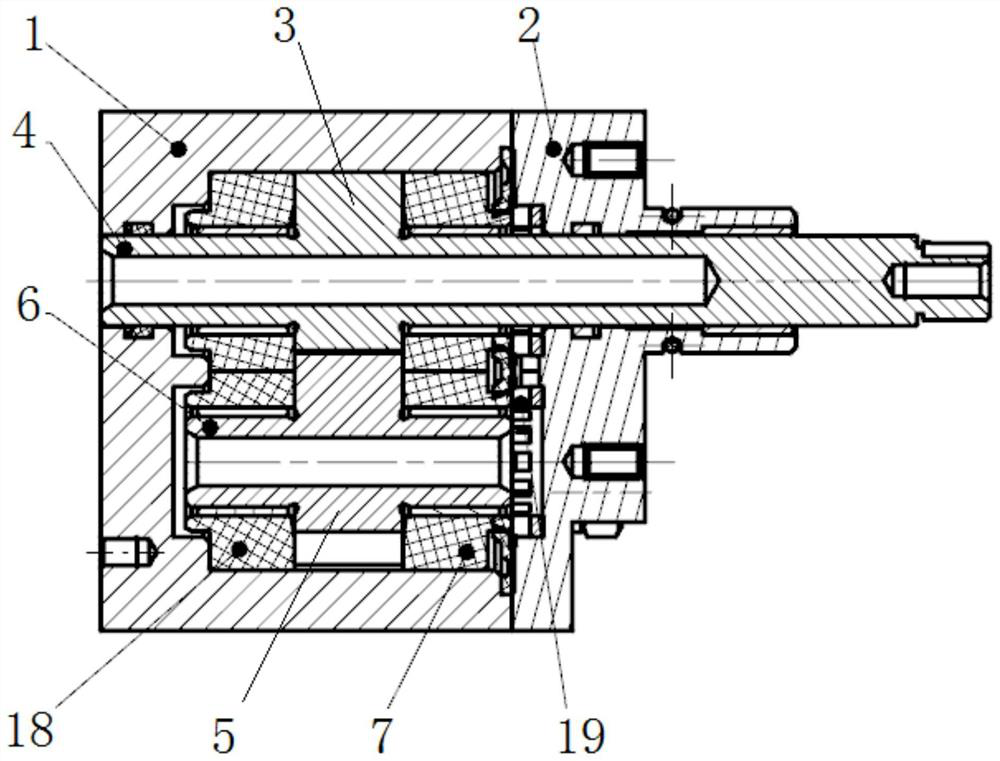

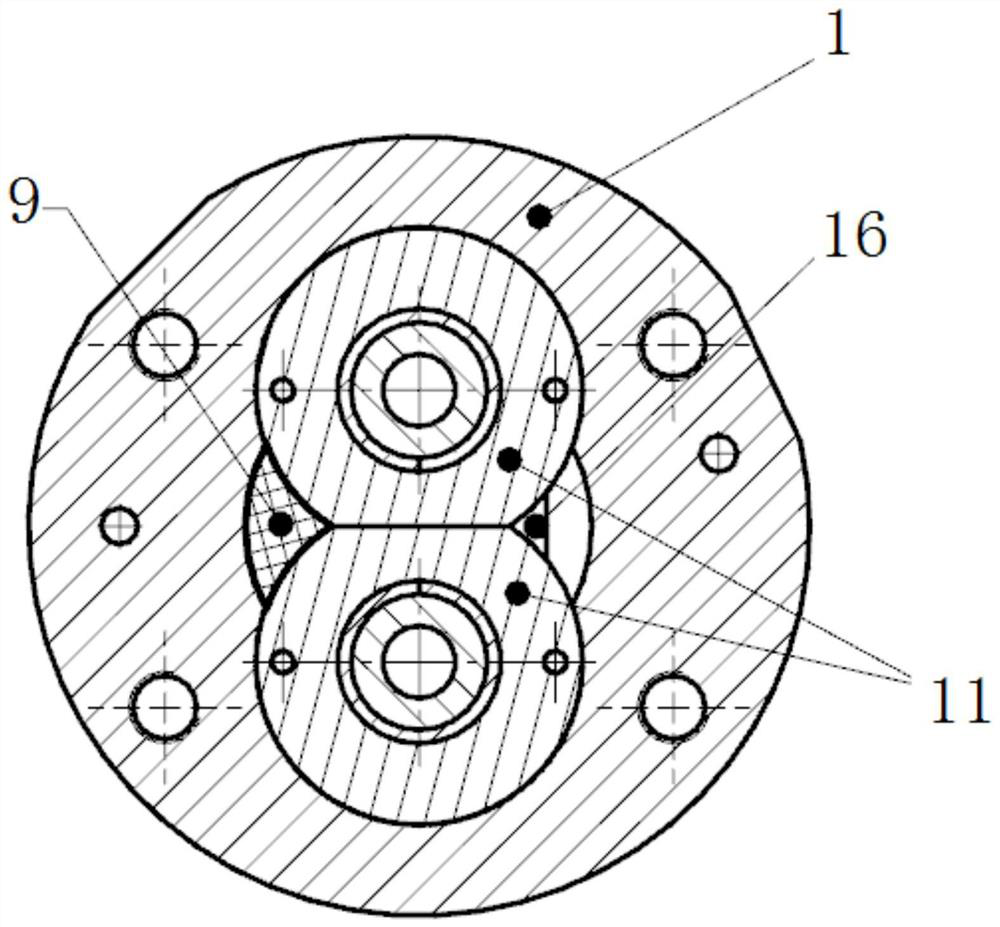

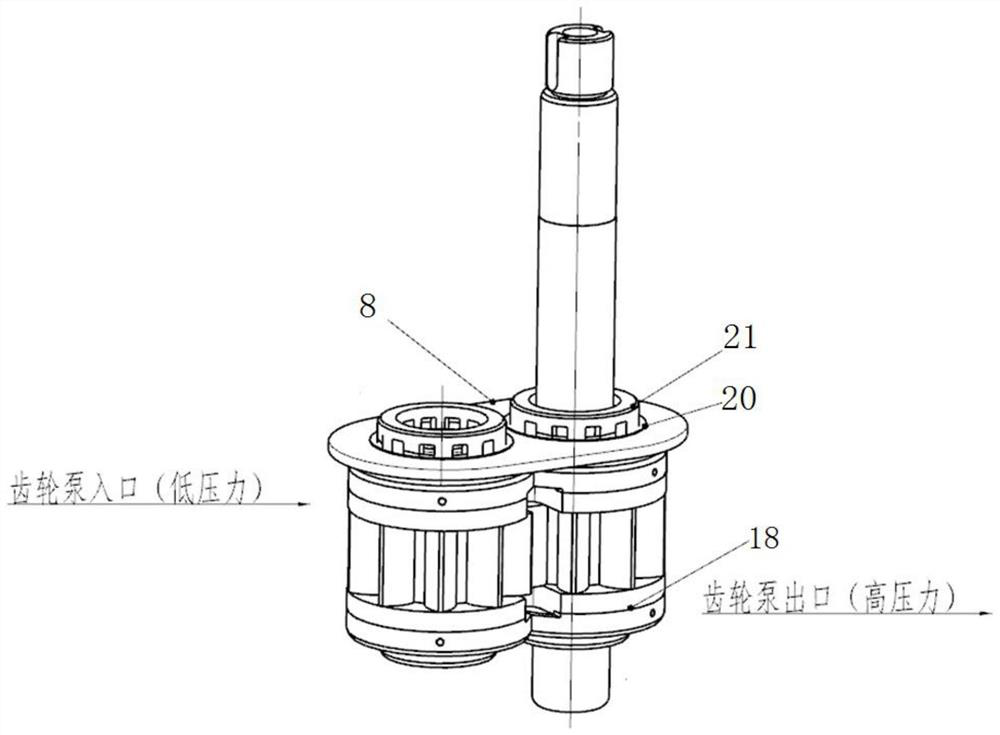

[0048] Such as Figure 1-Figure 11 As shown, the seawater pump used by the underwater self-launching device includes a pump body 1, a pump cover 2, a driving gear 3, a driven gear 5, a transmission shaft 4, a rotating shaft 6, a fixed side plate 18 and an axial compensation mechanism.

[0049] The driving gear is arranged on the transmission shaft, and the driven gear is arranged on the rotating shaft. The driving gear and the driven gear mesh to form a gear pair; the fixed side plate and the axial compensation mechanism are respectively arranged on both sides of the gear pair, and the axial compensation The mechanism is set close to the pump cover; in the design of the pump body, the asymmetric structure of the inlet flow channel and the outlet flow channel is adopted, which is convenient for distinguishing the inlet flow channel and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com