Batching hopper for die steel production

A technology of die steel and hopper, applied in the direction of charge, charge composition/state, charging processing type, etc., can solve the problem of inconvenient discharging and other problems, and achieve the effect of simple operation and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

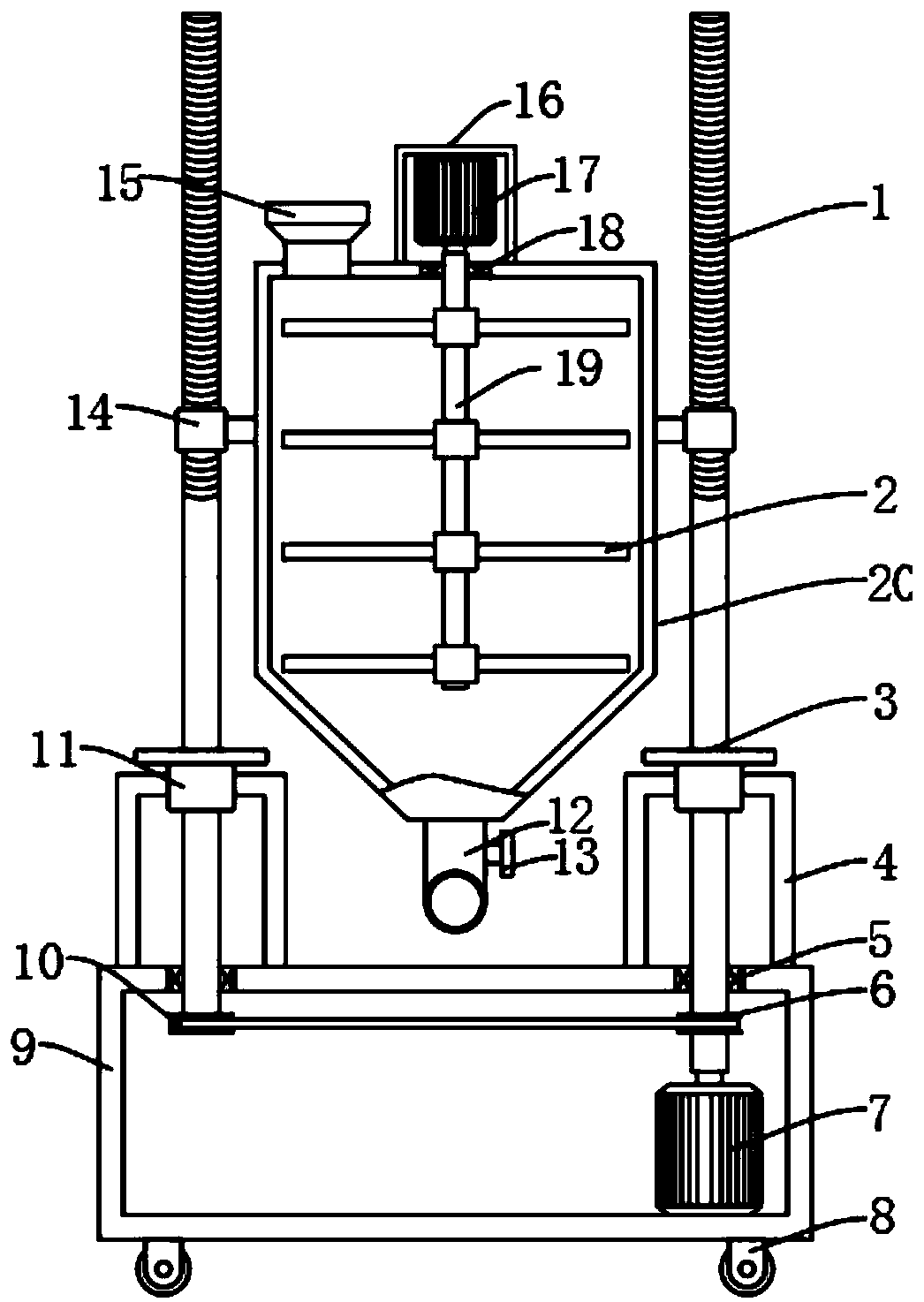

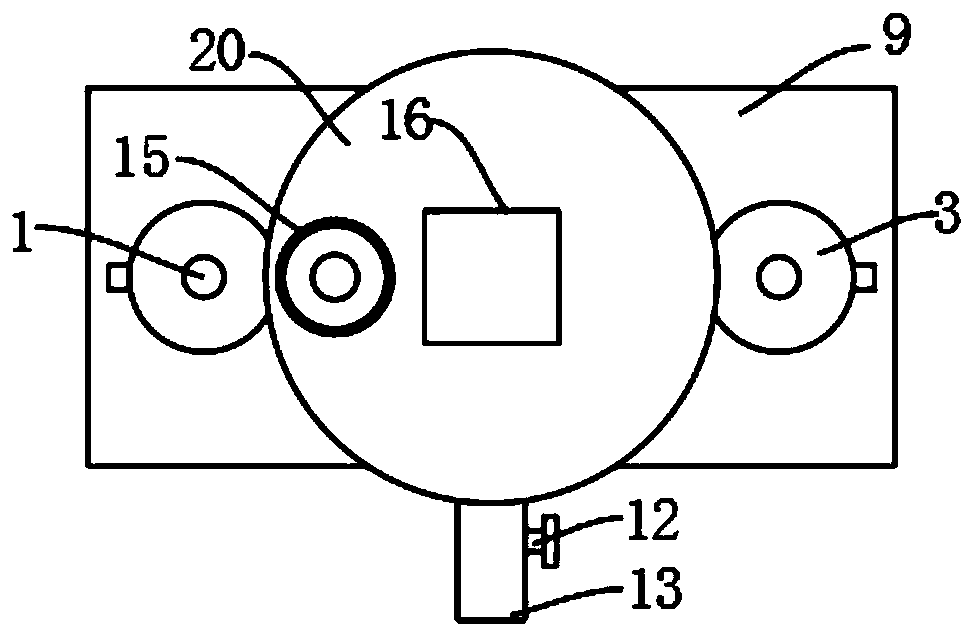

[0016] refer to Figure 1-2 , a batching hopper for the production of die steel, comprising a box body 9, the lower end of the box body 9 is fixedly connected with a roller 8, and both sides of the upper end of the box body 9 are fixedly connected with first bearings 5, and the inner parts of the two first bearings 5 The shaft surfaces are fixedly connected with a rotating shaft 1, the lower ends of the two rotating shafts 1 are connected by a transmission mechanism, the upper end of the rotating shaft 1 is provided with an external thread, the external thread is threaded with a threaded sleeve 14, and a housing 20 is fixedly connected between the two threaded sleeves 14 , the upper end of the housing 20 is connected to a feed port 15, and the lower end of the housing 20 is connected to a discharge pipe 12. The discharge pipe 12 is provided with a valve 13, and the first motor 7 moves forward to drive the rotating shaft 1. Rotate, so that the threaded sleeve 14 rises, drives t...

Embodiment 2

[0020] refer to figure 2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the transmission mechanism includes a rotating wheel 6 fixedly connected to the lower end of the rotating shaft 1, and a belt 10 is sleeved between the two rotating wheels 6, through which the belt 10 to the effect of transmission so as to drive the two rotating wheels 6 to rotate simultaneously.

Embodiment 3

[0022] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the lower ends of the two rotating shafts 1 are provided with connecting sleeves 11, and the opposite outer sides of the two connecting sleeves 11 are fixedly connected with L-shaped support rods 4, The lower end of the L-shaped support rod 4 is fixedly connected with the box body 9, and the rotating shaft 1 is fixedly connected with a support plate 3, and the support plate 3 abuts against the upper end of the connection sleeve 11, and the support plate 3 is supported by the connection sleeve 11, thereby The rotating shaft 1 plays a supporting role, which is beneficial to reduce the pressure of the gravity of the raw material on the first bearing 5 , thereby prolonging the service life of the first bearing 5 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap