Test fixtures for contactors

A technology for testing devices and contactors, which is applied in measuring devices, testing of machine/structural components, testing of mechanical components, etc., and can solve problems such as overtravel, burning, and welding of contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

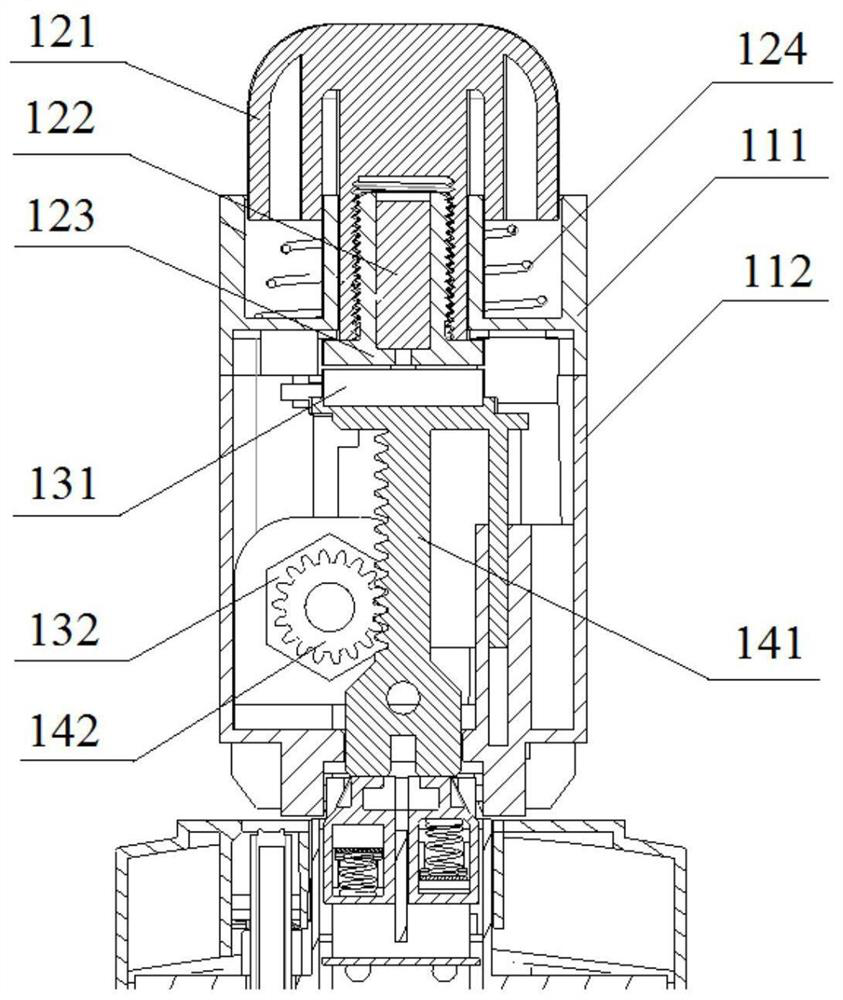

[0025] Various embodiments according to the present invention will be described in detail with reference to the accompanying drawings. Here, it is to be noted that, in the drawings, the same reference numerals are assigned to components having substantially the same or similar structures and functions, and repeated descriptions about them will be omitted. If not specifically stated, the term "sequentially including A, B, C, etc." only indicates the arrangement order of the included components A, B, C, etc., and does not exclude the inclusion of components between A and B and / or between B and C. Possibility of other components. .

[0026] The accompanying drawings in this specification are schematic diagrams, which assist in explaining the concept of the present invention, and schematically represent the shapes of various parts and their interrelationships.

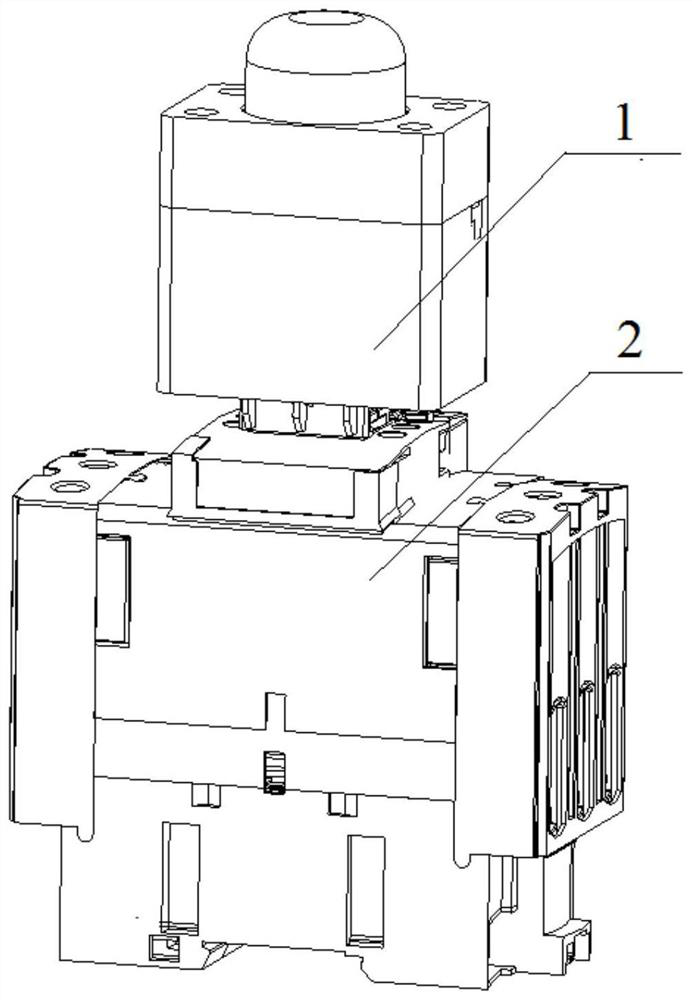

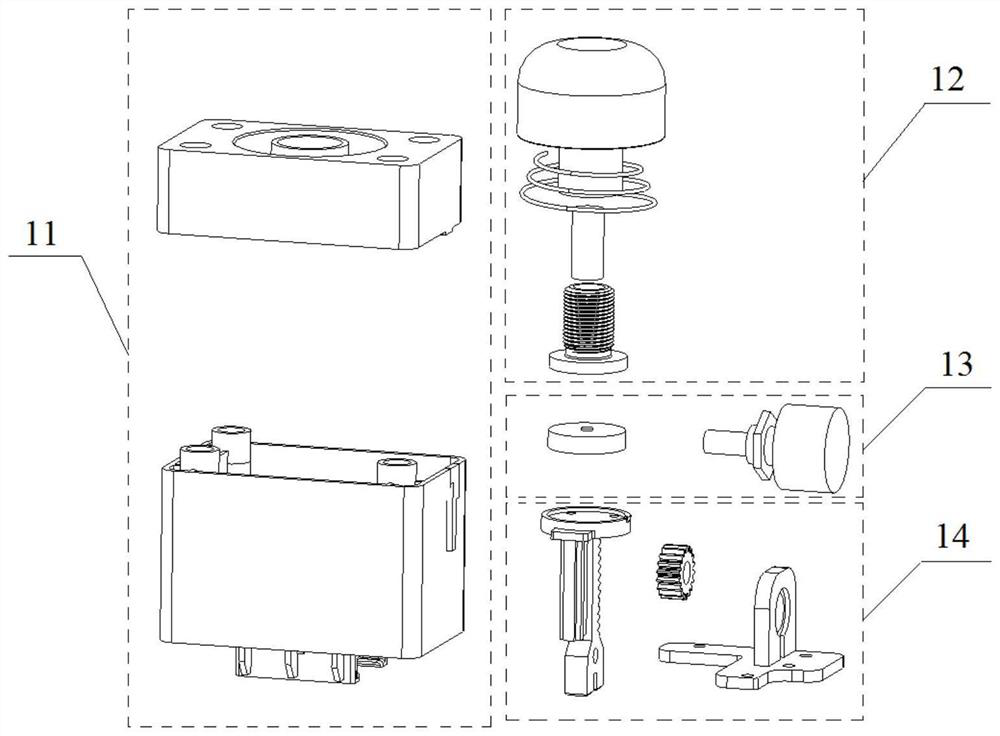

[0027] Below, refer to Figure 1 to Figure 11 , to describe in detail preferred embodiments according to the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com