Defect detection method for road deceleration strip

A detection method and technology of speed bumps, which are applied in image data processing, instruments, computing, etc., can solve the problems of affecting traffic safety, large amount of calculation and storage space, harm to vehicles and personnel, etc., so as to avoid waste of resources and improve computing speed. , the effect of high defect detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

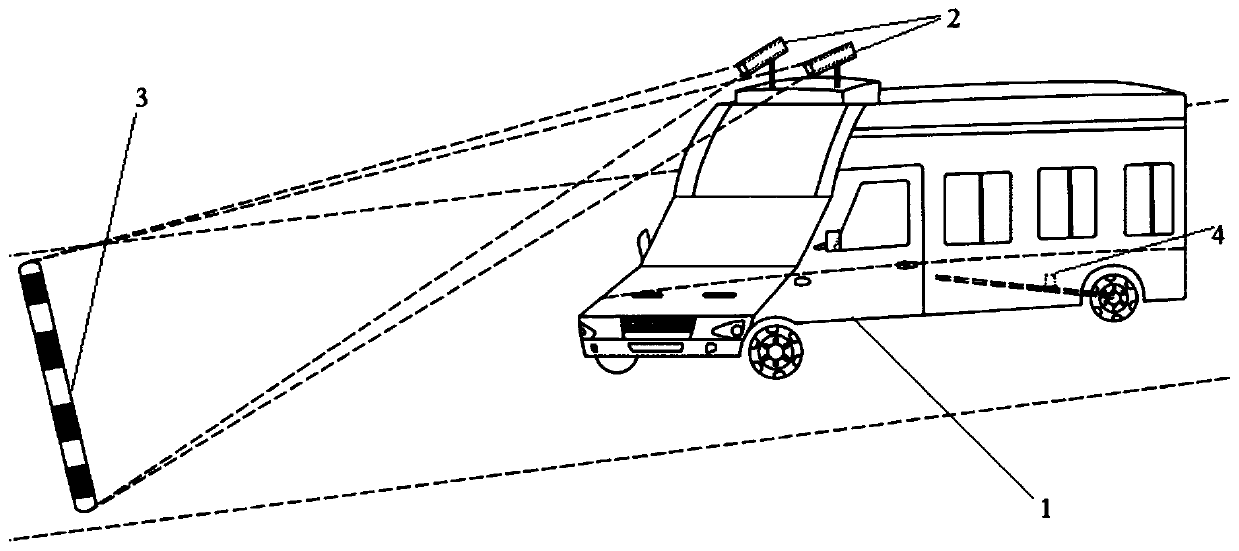

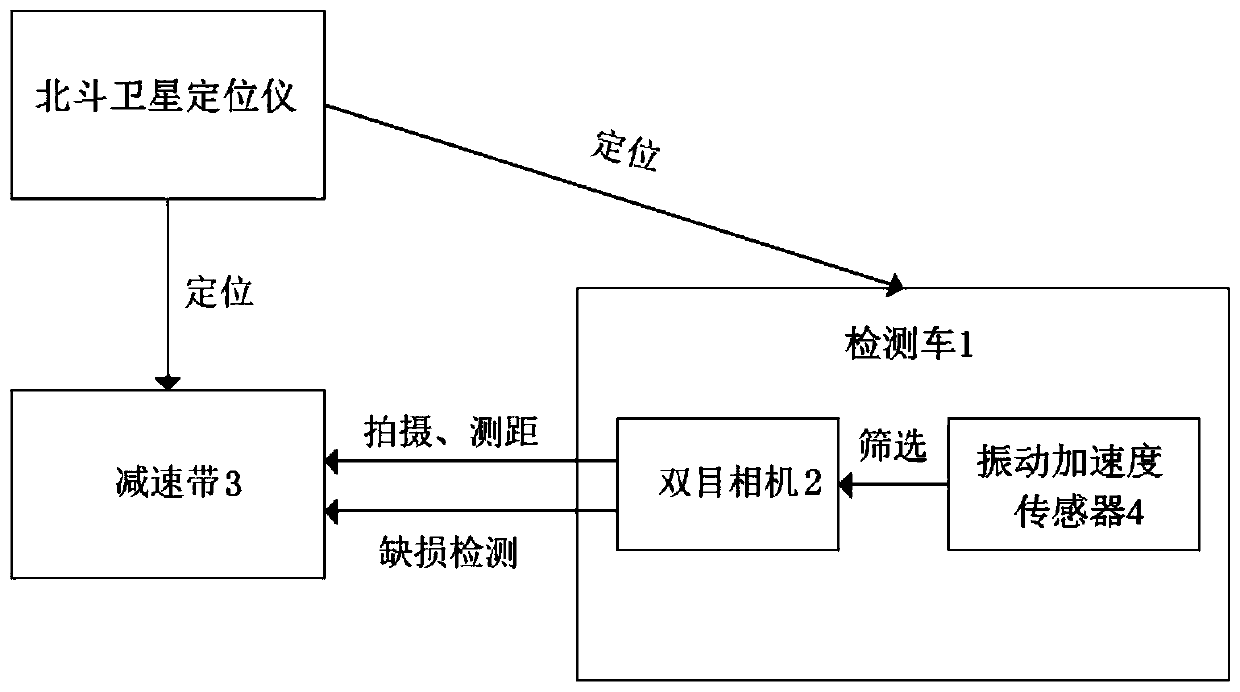

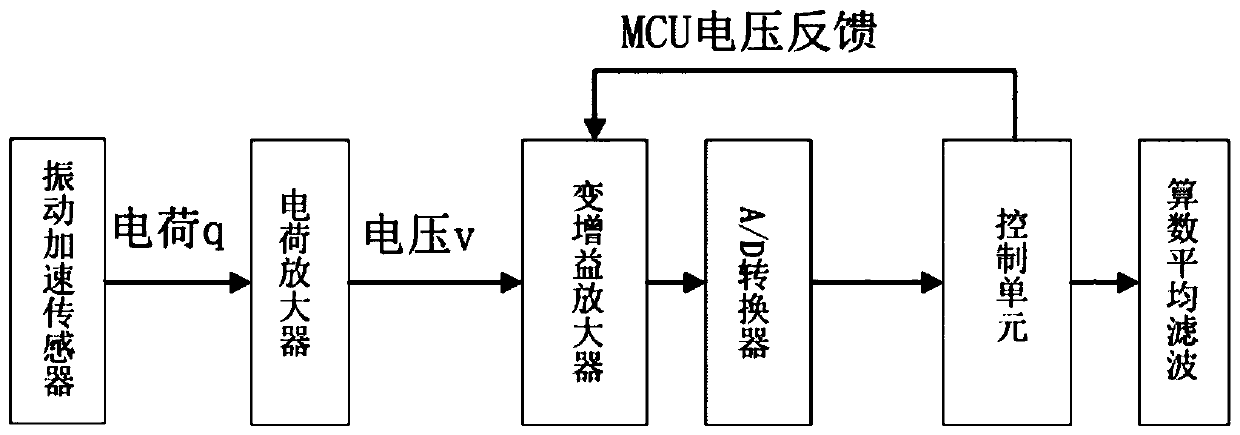

[0047] A defect detection method of a road deceleration belt of the present invention, such as figure 1 As shown, the binocular camera 2 is installed on the upper front of the detection vehicle 1 for real-time collection of road images in front of the detection vehicle 1 and images of the speed bump 3, and the vibration acceleration sensor 4 is installed on the magnetic mounting base, which absorbs On the rear axle of the detection vehicle 1, it is used to collect the vibration signal during the operation of the detection vehicle 1, and then determine whether the detection vehicle 1 passes the deceleration belt 3. The rotary encoder is installed on the rear wheel side of the detection vehicle 1, which can collect Stable speed information, Beidou satellite locator and industrial computer are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com