Method for protocol conversion between robot and welding equipment and protocol conversion module

A technology of protocol conversion and welding equipment, applied in the field of communication, can solve the problems of complexity, it is difficult for the CPU to realize multiple functions, and it is difficult for a single protocol to adapt to the market, etc., to achieve the effect of reducing conversion costs and fast connection and transmission speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

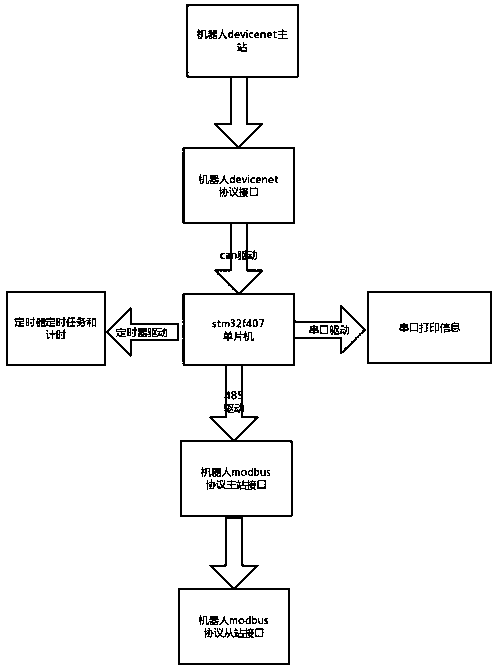

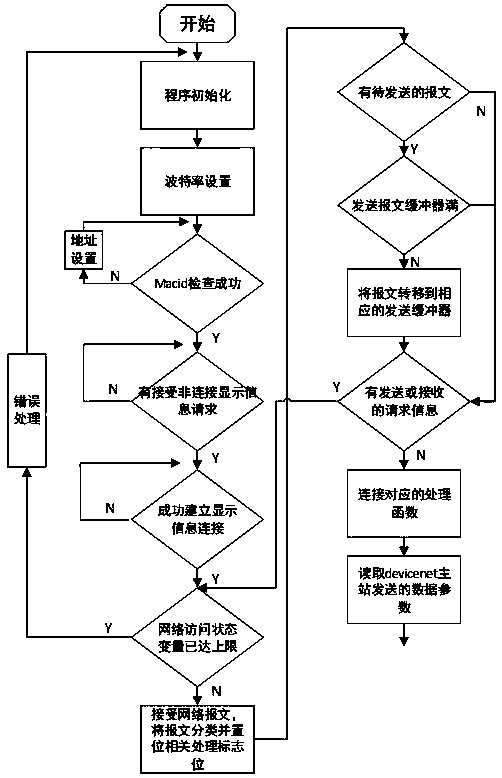

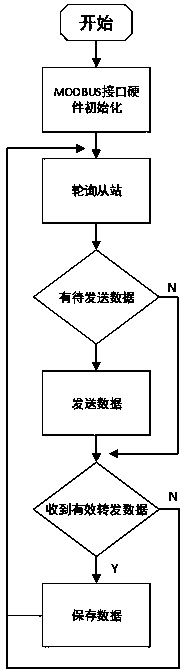

[0036] The method for the protocol conversion between the robot and the welding equipment provided by the present invention converts the devicenet protocol into the modbus protocol, and the schematic diagram is as follows figure 1 Said, use the devicenet interface to pass the received data to the processor chip through the CAN bus conversion chip with the isolation circuit, after the analysis of the processor chip, initialize the modbus interface, and then pass it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com