Efficient wig product hair pressing machine

A technology for rewinding machine and wig, applied in the direction of wig, clothing, application, etc., can solve the problems of difficult to control the temperature of ironing, scalded hair root of wig, low production efficiency, etc., achieve ingenious structure, reduce high defective rate, The effect of high power transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

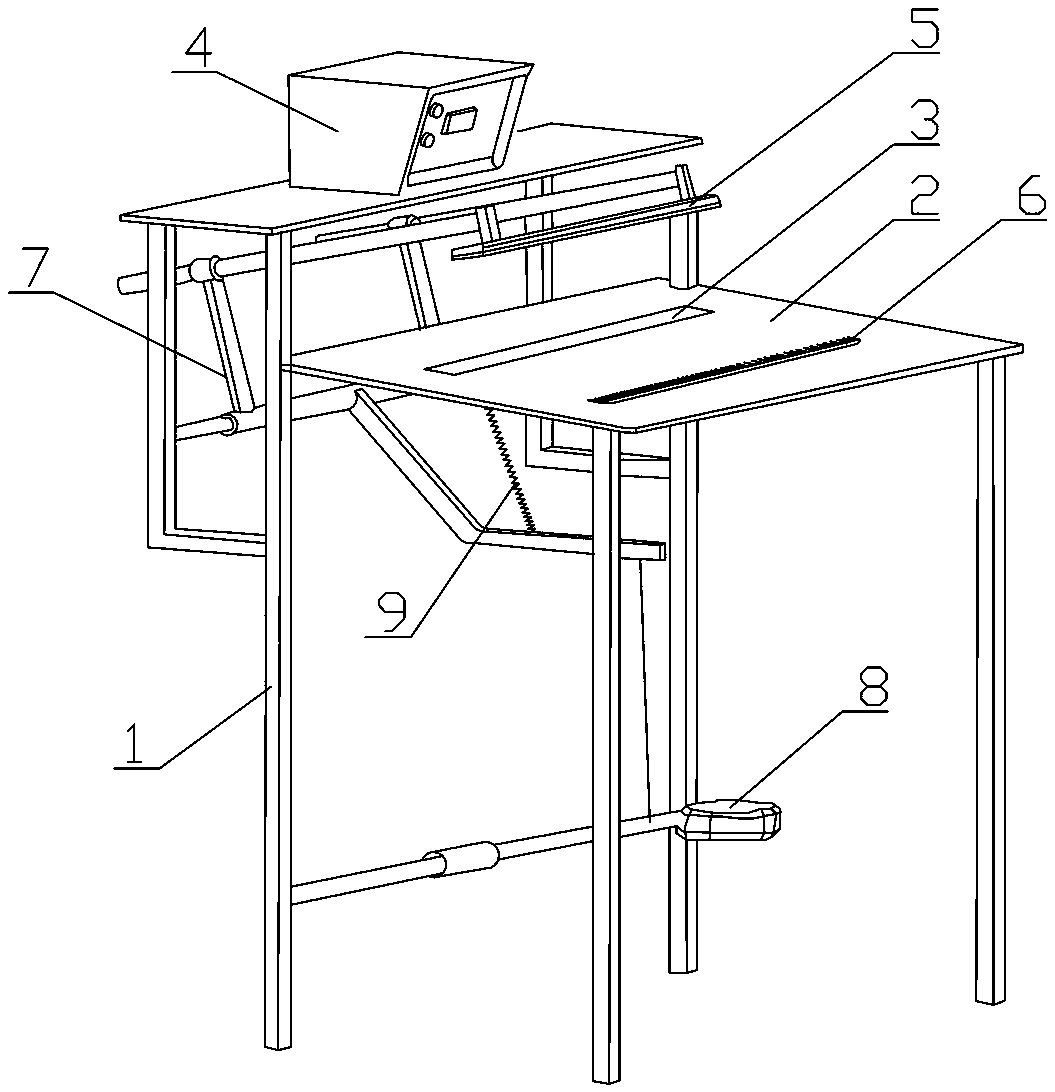

[0014] In this embodiment, a high-efficiency unhairing machine for wig products has a support 1, a work surface 2 is provided on the support 1, a heating panel 3 is provided on the work surface 2, and a control heating panel is also provided on the support 1 3 temperature control device 4, working platen 5 for hot-pressing wig products and power components for controlling the work of the working platen 5, and a long comb 6 matching the heating panel 3 is also placed on the worktable 2.

[0015] In this embodiment, the working platen 5 has a platen body that matches the heating panel 3. The platen body is composed of a steel plate bottom and a rubber layer. The platen body is located above the heating panel and is hingedly mounted on the bracket through a connecting rod 7. 1; the power transmission assembly has a foot pedal 8 located at the bottom of the bracket 1, the foot pedal 8 is in transmission connection with the working platen 5 through a multi-link device, and the foot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com