Cabinet type stirrer for freeze-dried food

A technology for mixers and foods, which is applied to mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve problems such as inconvenient unloading, and achieve the effect of convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

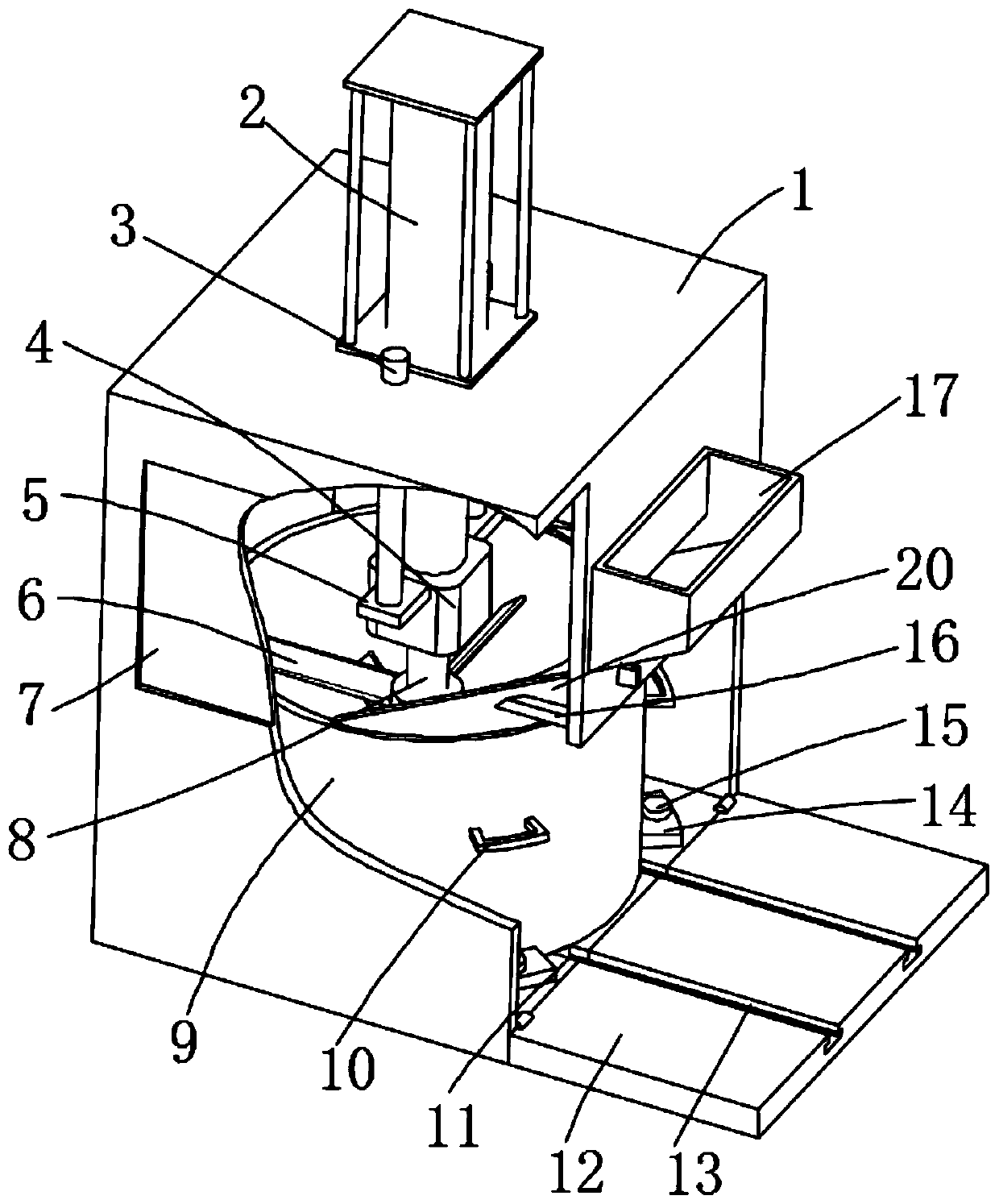

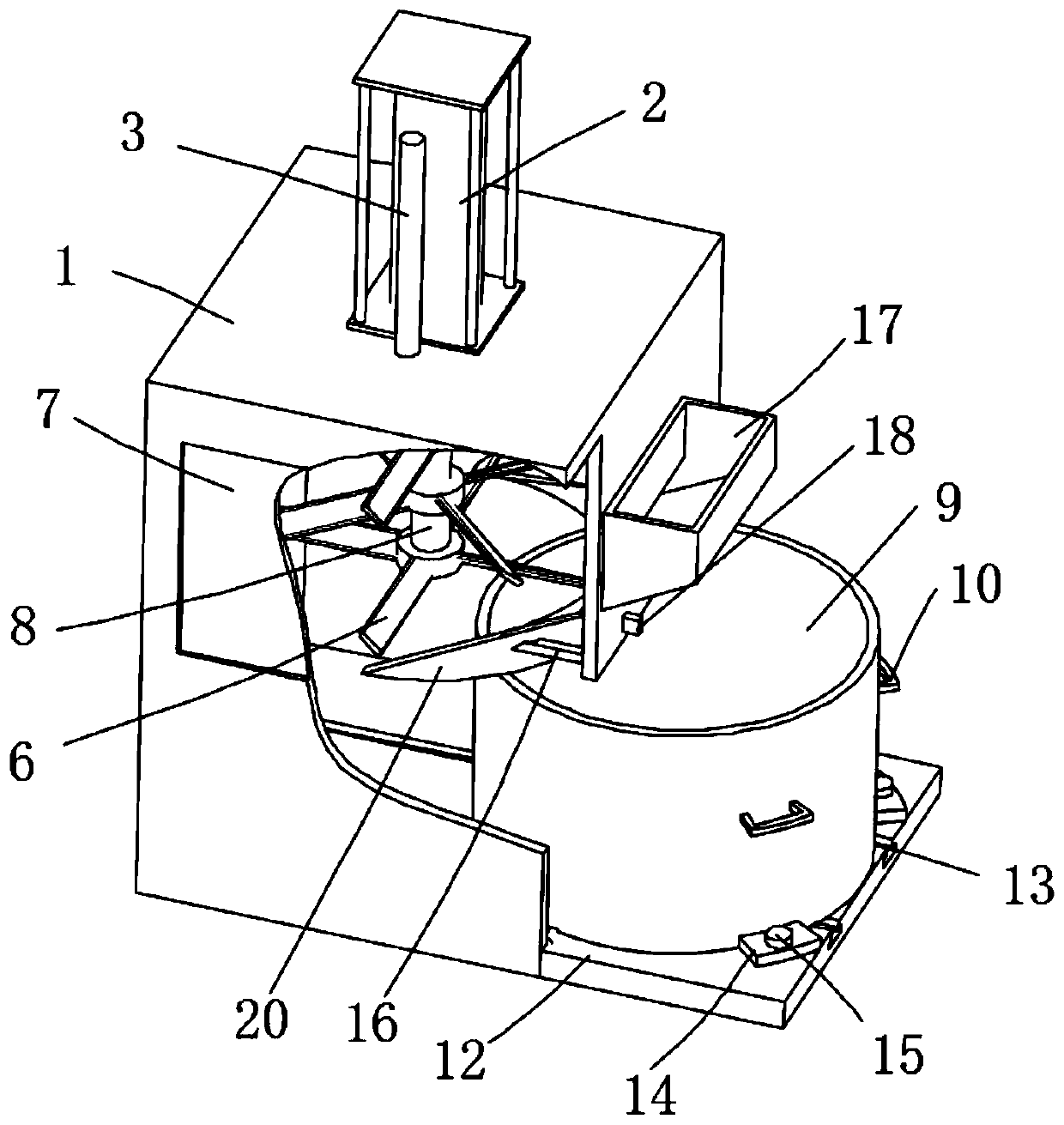

[0027] A cabinet blender for freeze-dried food such as figure 1 and figure 2 As shown, it includes a cabinet body 1, the top outer wall of the cabinet body 1 is connected with an air rod 2 by screws, and the bottom outer wall of the air rod 2 is connected with a drive box 4 by screws, and the output shaft of the drive box 4 is fixedly connected with a rotary rod 8. The side outer wall of the rotating rod 8 is welded with evenly distributed stirring rods 6, the bottom inner wall of the cabinet body 1 is provided with an inner chute 11, and the bottom inner wall of the cabinet body 1 is provided with a mixing drum 9, and the bottom outer wall of the mixing drum 9 is provided with a The slide bar matched with the inner chute 11 is slidably connected to the side inner wall of the inner chute 11 , a side outer wall of the cabinet body 1 is provided with a feeding chute, and the side inner wall of the feeding chute is welded with a hopper 17 .

[0028] For the convenience of obser...

Embodiment 2

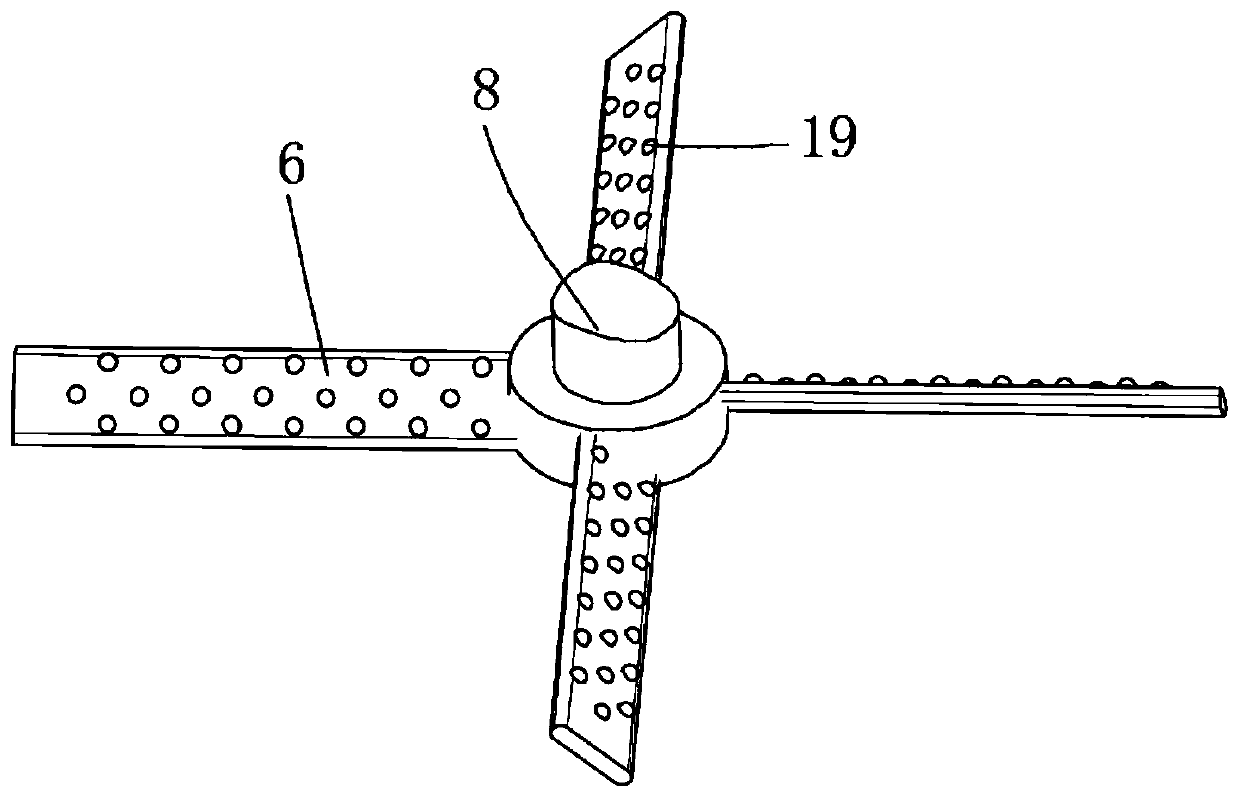

[0036] A cabinet blender for freeze-dried food such as image 3 As shown, in order to improve the stirring effect of the freeze-dried food; this embodiment makes the following improvements on the basis of embodiment 1: uniformly distributed protrusions 19 are arranged on the side outer wall of the stirring rod 6 .

[0037] When this embodiment is in use, compared with Embodiment 1, when the stirring rod 6 stirs the freeze-dried food, the protrusion 19 can hit the outside of the freeze-dried food, thereby improving the effect of stirring the freeze-dried food.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap