A treatment system and treatment process for bulky waste

A treatment system and treatment process technology, applied in the field of bulky waste treatment, can solve problems such as troublesome cleaning, falling to the ground, etc., and achieve the effects of good purification, increasing contact area, and reducing odor emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

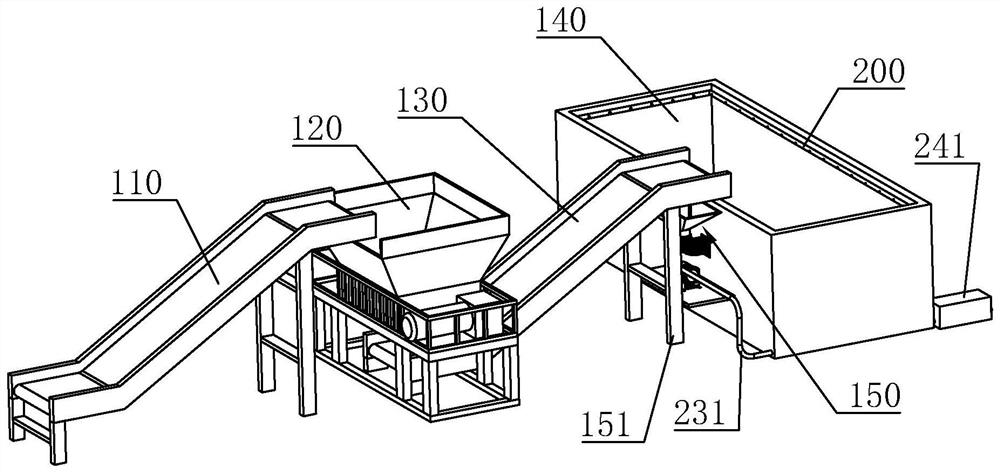

[0043] A treatment system for bulky waste, with reference to figure 1, comprising a feed conveyor belt 110, a crusher 120, and a discharge conveyor belt 130 connected in sequence, one end of the feed conveyor belt 110 is located above the crusher 120, and one end of the discharge conveyor belt 130 is located below the crusher 120, and the discharge Below the other end of the conveyor belt 130, there is a collection box 140, and the bulky garbage to be crushed is placed on the feeding conveyor belt 110, transported to the crusher 120 through the feeding conveyor belt 110, and then crushed to form pieces of garbage. After the pieces of rubbish fall onto the discharge conveyor belt 130 , they are transported into the collection compartment 140 .

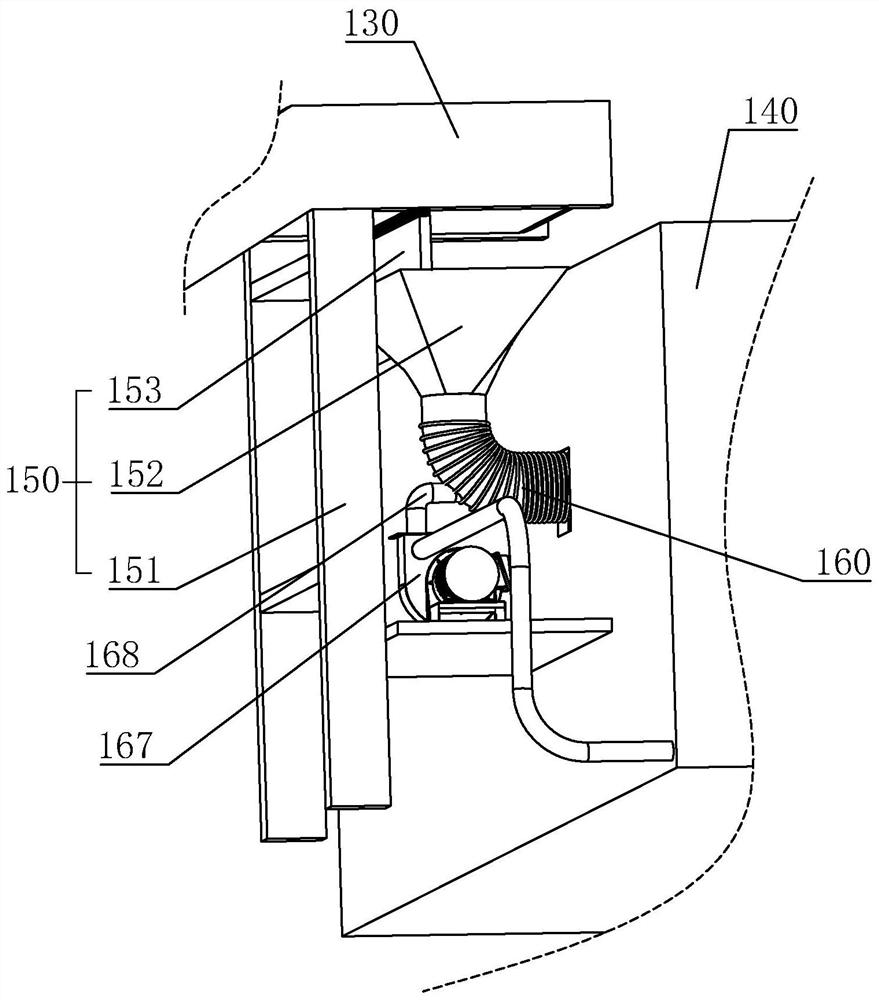

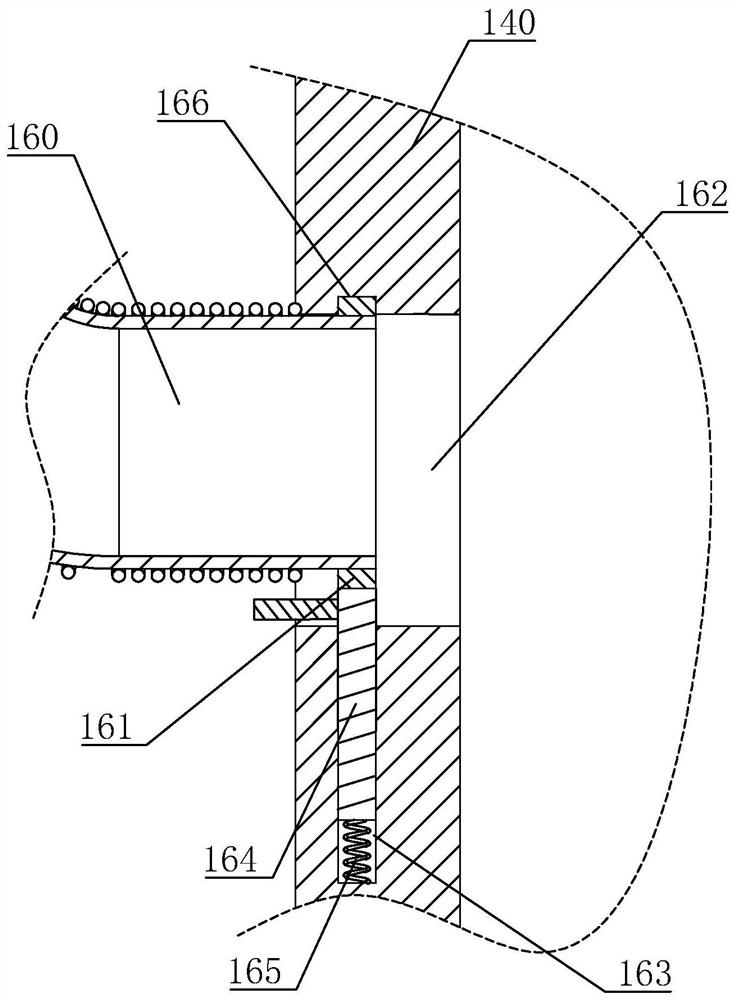

[0044] refer to figure 2 , image 3 , the lower side of the discharge conveyor belt 130 is provided with a scrap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap