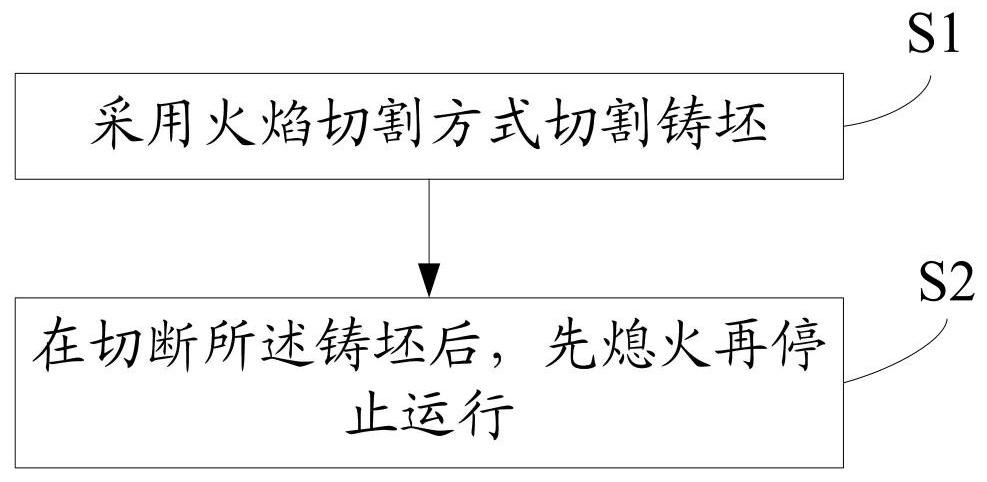

A Method for Preventing Flame Cutting Cracks from Casting Slabs

A flame cutting and casting billet technology, applied in the field of slab continuous casting, can solve the problems of flame cutting surface cracks, affecting rolling use, and having little effect, so as to prevent flame cutting cracks, reduce flame cutting time, and reduce thermal effects. The effect of area thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Steel type HC420LA, with carbon content of 0.07%, niobium content of 0.05%, silicon content of 0.34%, and manganese content of 1.10%, is cut by double guns. After cutting the billet, the cutting gun first turns off the flame and then stops the operation. The end face of the billet is not cut crack;

Embodiment 2

[0028] Example 2: Steel type HC420LA, with carbon content of 0.06%, niobium content of 0.05%, silicon content of 0.33%, and manganese content of 1.10%, is cut by double guns. After the cutting gun cuts the billet, it first turns off the flame and then stops the operation. The end face of the billet is not cut crack;

Embodiment 3

[0029] Example 3: Steel type M4R22, with carbon content of 0.08%, niobium content of 0.04%, silicon content of 0.46%, and manganese content of 1.15%, is cut by double guns. After the cutting gun cuts the billet, it first turns off the flame and then stops the operation. The end face of the billet is not cut crack.

[0030] Below in conjunction with specific embodiment this scheme is further introduced:

[0031] There are two main reasons for cutting cracks. One is that the temperature of the slab rises during flame cutting, which leads to local phase transformation, and phase transformation stress is generated at this position; the other is the characteristics of the steel type, or the segregation is more serious, resulting in uneven mechanical properties of the slab. Or it is highly sensitive to compositional cracks. This patent mainly solves the cutting cracks of crack-sensitive steel types. The main technical idea is to reduce the thickness of the heat-affected zone of cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com