Laser marking machine for fruits

A laser marking machine, fruit technology, applied in the field of laser marking, can solve the problems of slow speed, low efficiency, no orange continuous laser marking equipment, etc., and achieve the effect of fast marking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

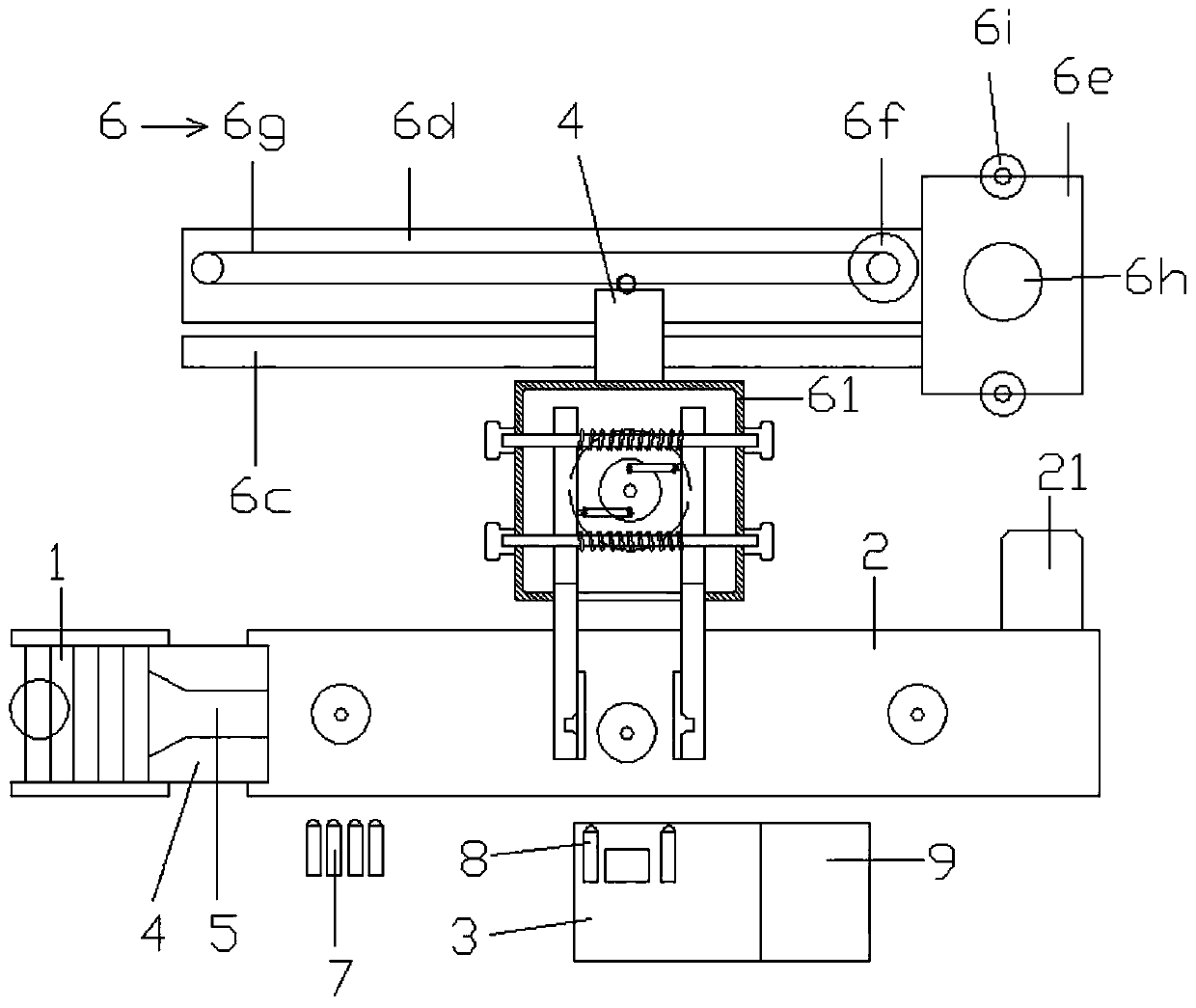

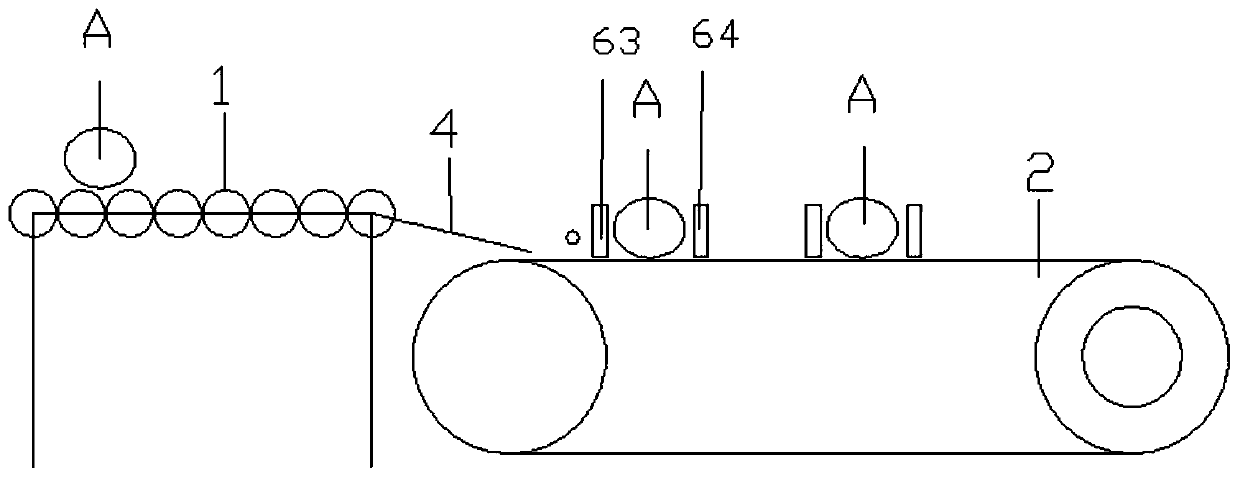

[0017] Example: see Figures 1 to 3 As shown, the fruit laser marking machine includes a roller conveyor belt 1, an aluminum plate conveyor belt 2 and a laser marking machine 3, and the aluminum plate conveyor belt 2 is driven by an aluminum plate conveyor belt driving motor 21; it is characterized in that: the roller conveyor belt 1 A blanking guide plate 4 is fixed on the bracket at the output end, and a guide groove 5 is fixed on the blanking guide plate 4. The guide groove 5 has a trumpet-shaped entrance, and the blanking guide plate 4 forms an angle of 30 to 60 degrees with the horizontal plane. The blanking guide plate 4 Facing the aluminum plate conveyor belt 2 and located above the aluminum plate conveyor belt 2;

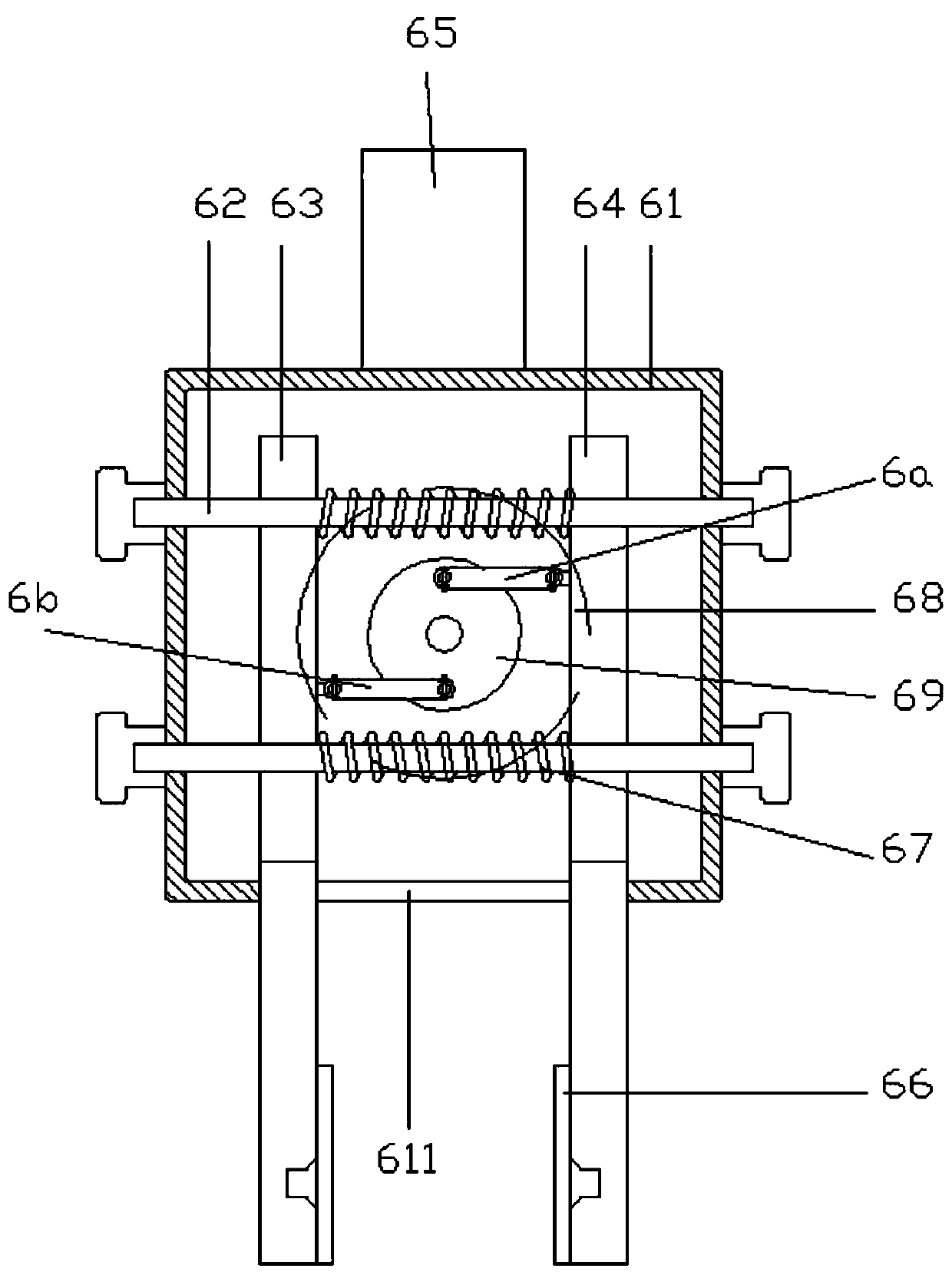

[0018] The structure of the feeding manipulator 6 is: a guide rod 62 is fixed in the casing 61, the left clamp arm 63 and the right clamp arm 64 are all inserted and sleeved on the guide rod 62, the upper end of the casing 61 is fixed with a slide block 65, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap