Storage battery plastic shell machining and cooling device

A technology of cooling device and battery, applied in battery pack parts, metal processing equipment, battery box/jacket, etc., can solve problems such as inability to cool workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

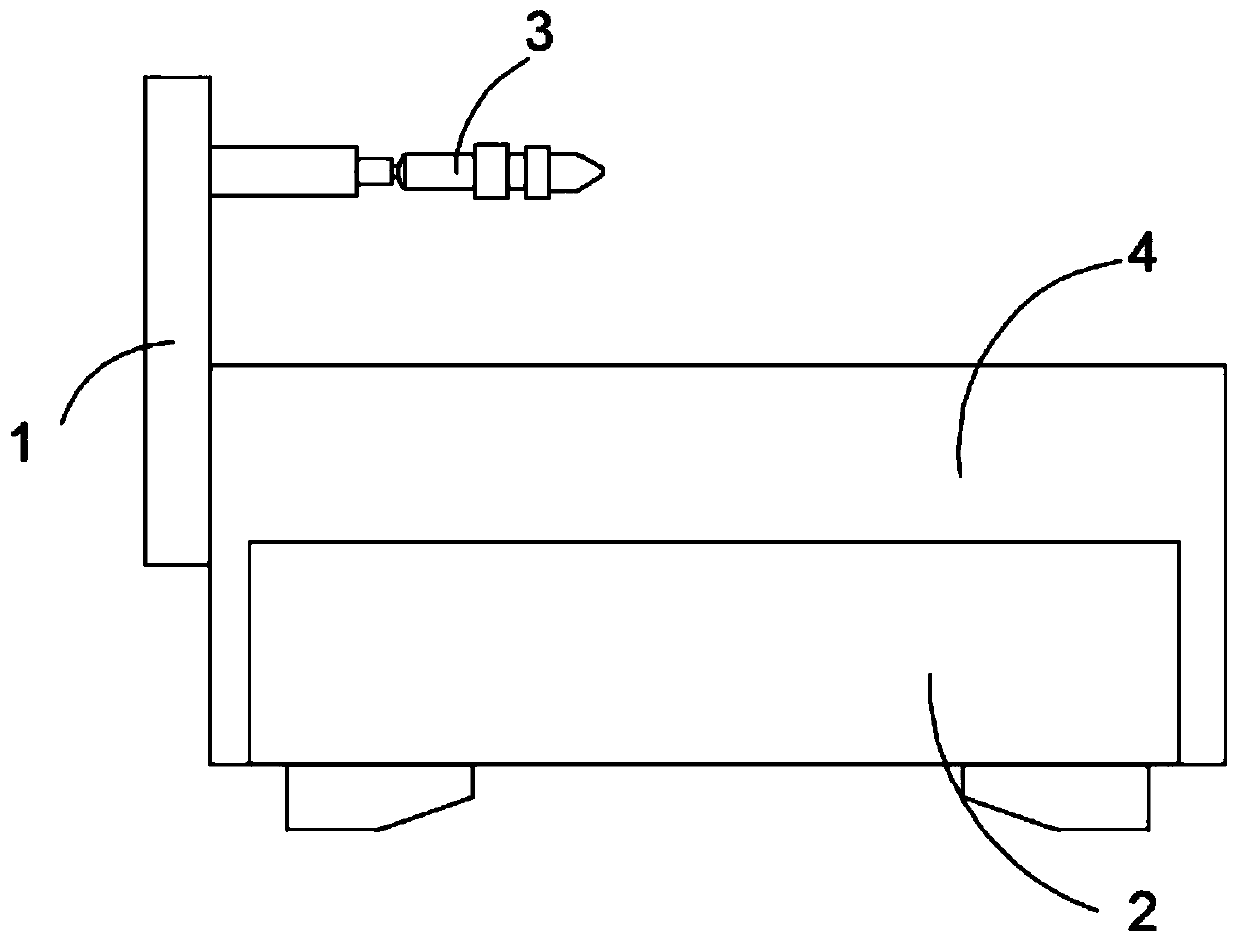

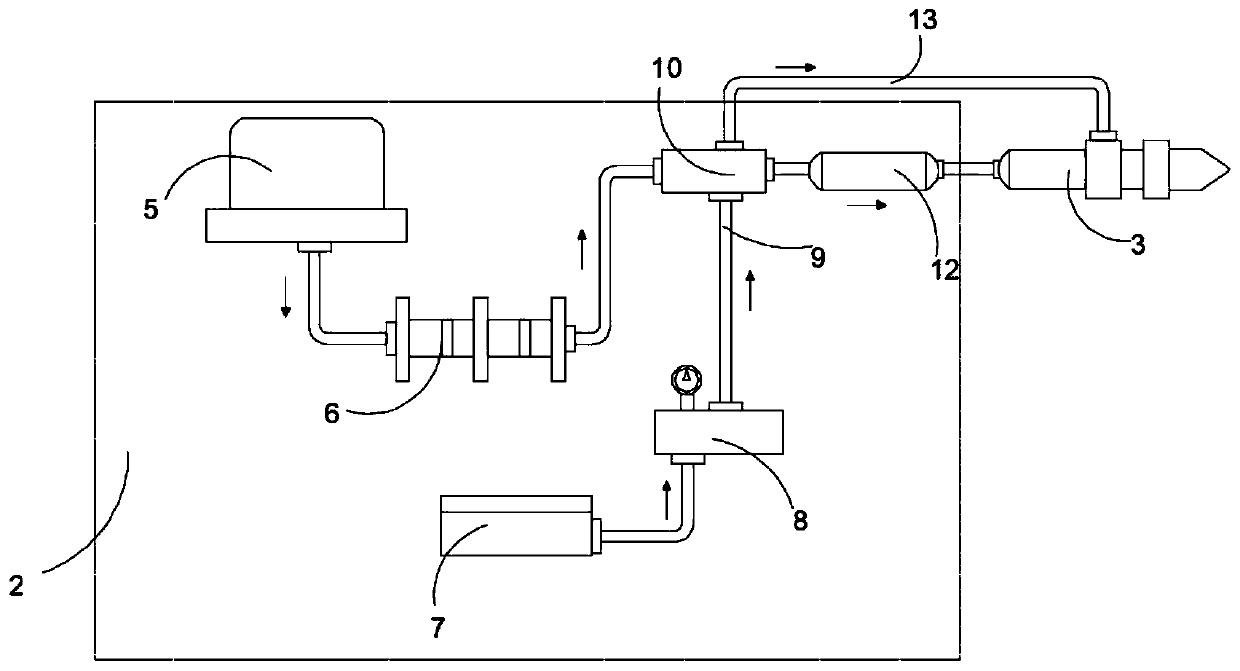

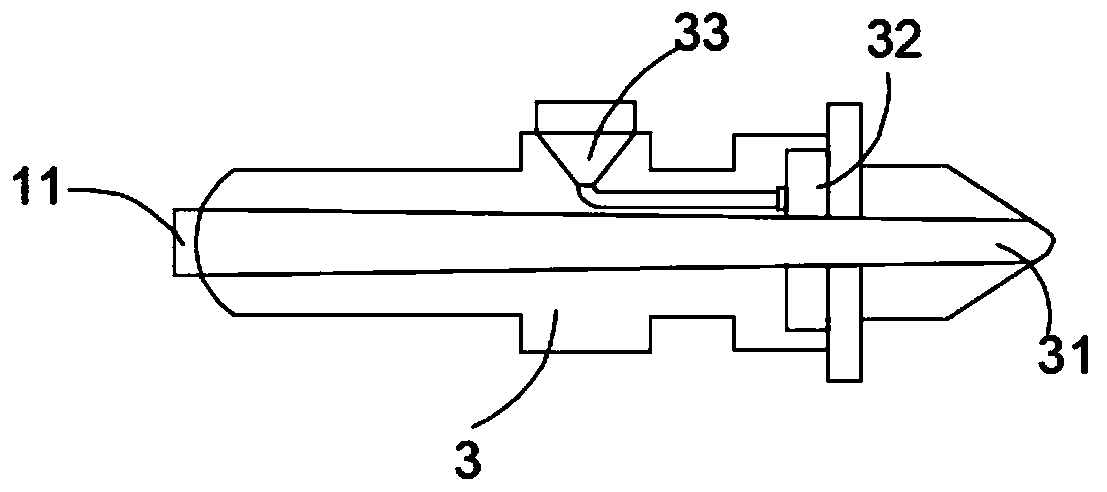

[0025] see Figure 1-4 , the present invention provides the following technical solutions: a battery molded case processing cooling device, including an X-Y axis movable frame 1, a water jet cutting assembly 2, a water jet nozzle 3 and a workbench 4, and the side of the workbench 4 is equipped with an X-Y axis The movable frame 1 is fixedly connected with the water jet nozzle 3 on the X-Y axis movable frame 1, and the water jet cutting assembly 2 is installed inside the working table 4. The water jet nozzle 3 is mainly composed of a water jet cutting pipe 31, a cooling sprinkler 32 and a The spraying water inlet 33 is composed of a water jet cutting pipe 31 installed inside the water jet nozzle 3. One end of the water jet cutting pipe 31 is connected to the outlet of the water jet nozzle 3, and the other end is fixedly connected to the water jet water inlet 11. The water jet nozzle The outer wall of 3 is equipped with a cooling spray inlet 33, and the outer wall of the water j...

Embodiment 2

[0032] like Figure 1 to Figure 4 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as Figure 4 As mentioned above, the sprinkler water inlet 321 is installed on the cooling sprinkler 32, and the sprinkler water inlet 321 is connected to the cooling spray water inlet 33 through a connecting pipe.

[0033] The sprinkler water inlet 321 is connected to the cooling spray inlet 33 through a connecting pipe, so that the water entering the cooling spray inlet 33 flows through the connecting pipe to the cooling sprinkler 32, thereby cooling the plastic case of the cold battery spray.

[0034]The working principle and application process of the present invention: the present invention places the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com