Integral molding process of composite material reflector

A technology of composite materials and molding process, which is applied in the field of composite mirror integrated molding technology, can solve the problems of low surface shape accuracy, long preparation cycle, poor stability, etc., achieve universality and wide adaptability, improve preparation efficiency and Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The parameters of the long-wave infrared carbon fiber mirror to be prepared are as follows: the thickness is 4.8mm, the aperture is 200mm, the radius of curvature is 700mm, the surface accuracy RMS is λ / 30 (λ=10.6μm), and the base type can be used.

[0037] The integrated molding process of the long-wave infrared carbon fiber mirror includes the following steps:

[0038] Step 1: Determine the design plan of the mirror blank according to the diameter, thickness, radius of curvature, surface shape accuracy, and base support type of the mirror, and optimize the support form of the base.

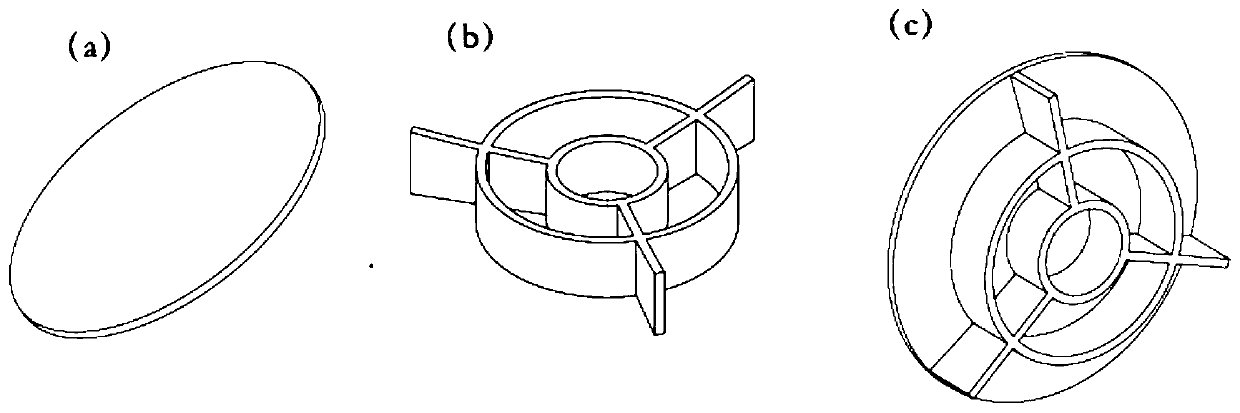

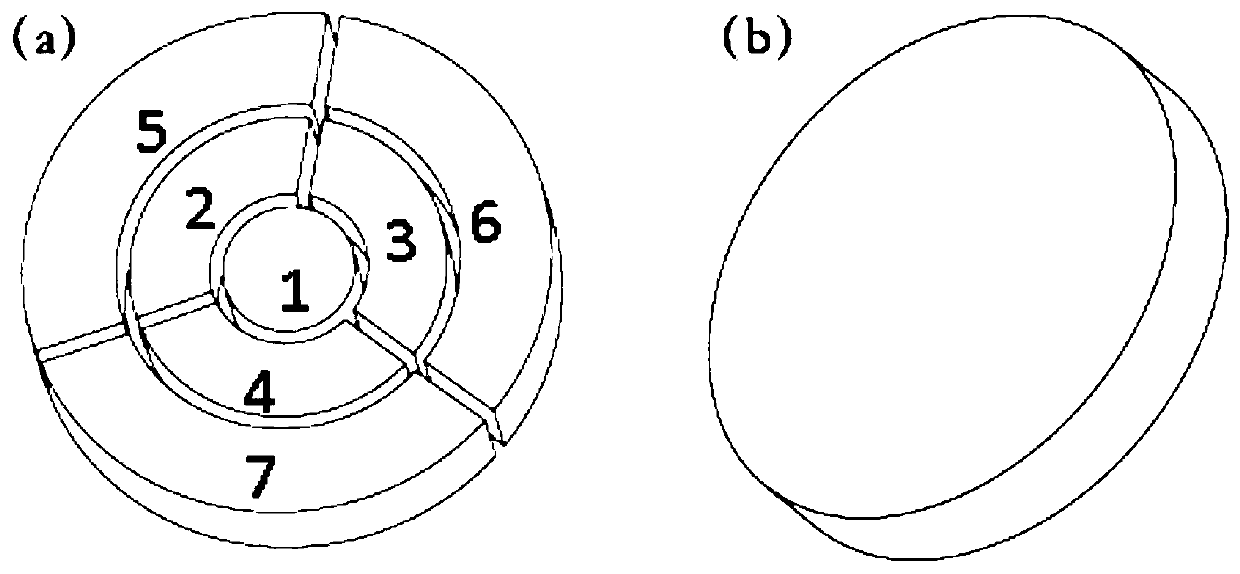

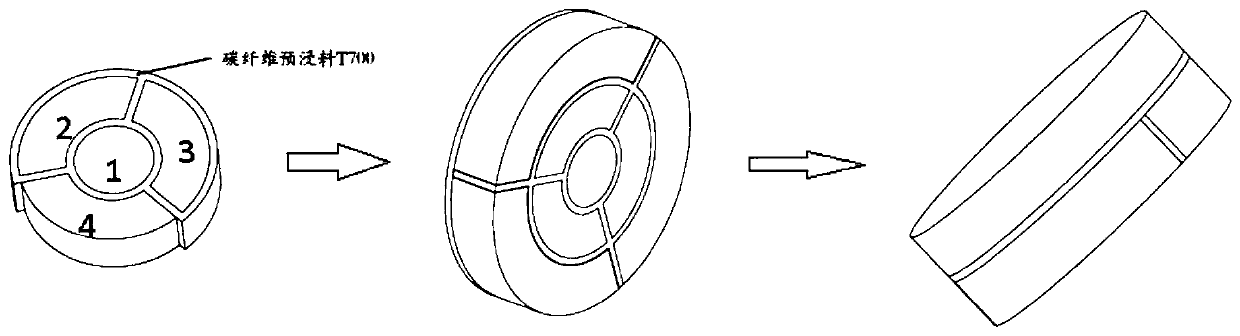

[0039] Among them, based on the classical laminate theory, the composite material is selected as carbon fiber prepreg T700, and the lay-up scheme is determined as [0 90 45 -45] 12S . Moreover, the base support form is selected through design simulation analysis as follows: figure 1 (b) shown.

[0040] Step 2: According to the design plan of the mirror blank and the base, use the compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com