Slip cylinder

A technology of chute and transition material, which is applied in the field of chute, can solve the problems of chute colliding with the cabin cover plate, chute damage, etc., and achieve the effects of facilitating assembly and transportation, improving service life and reducing relative friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

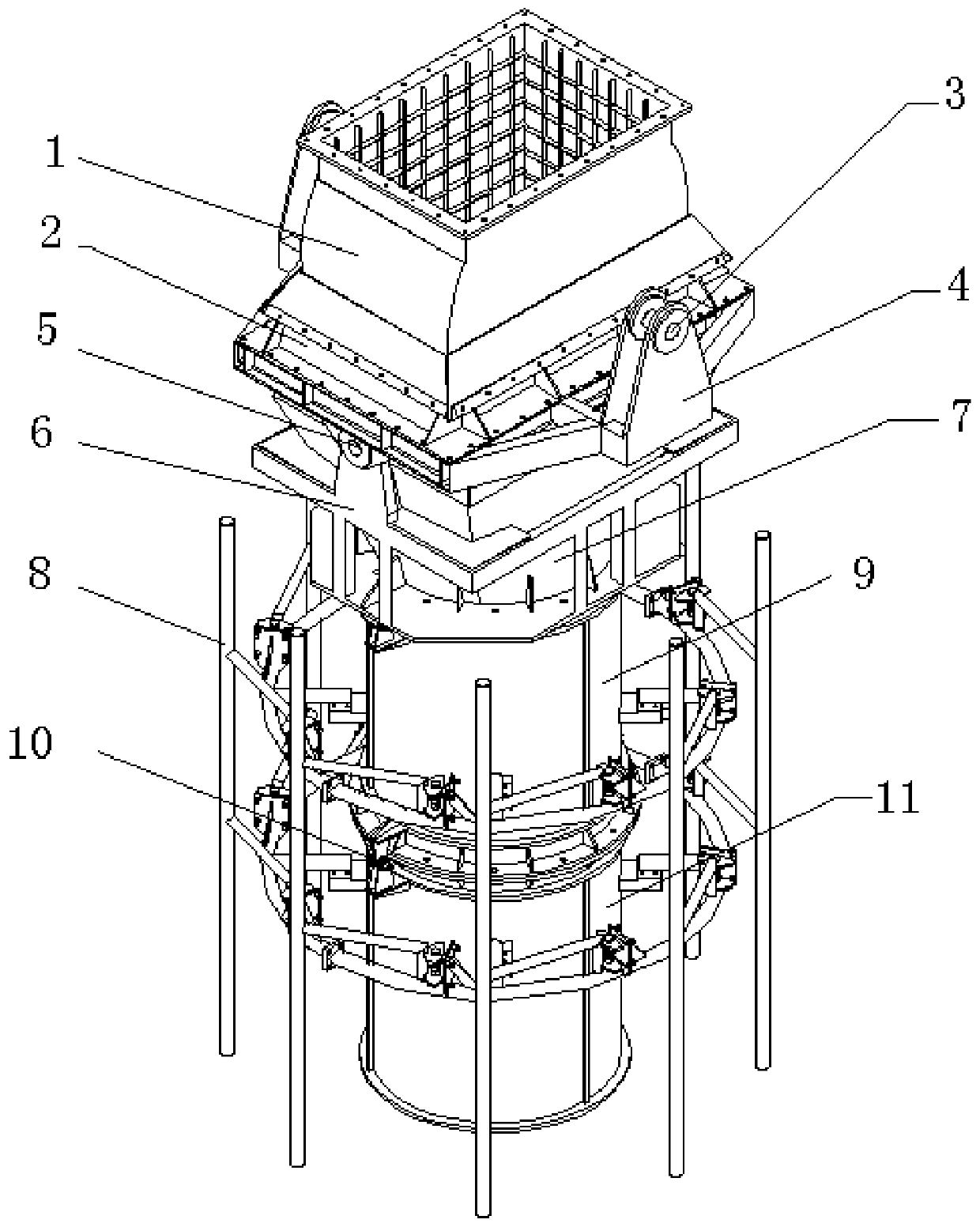

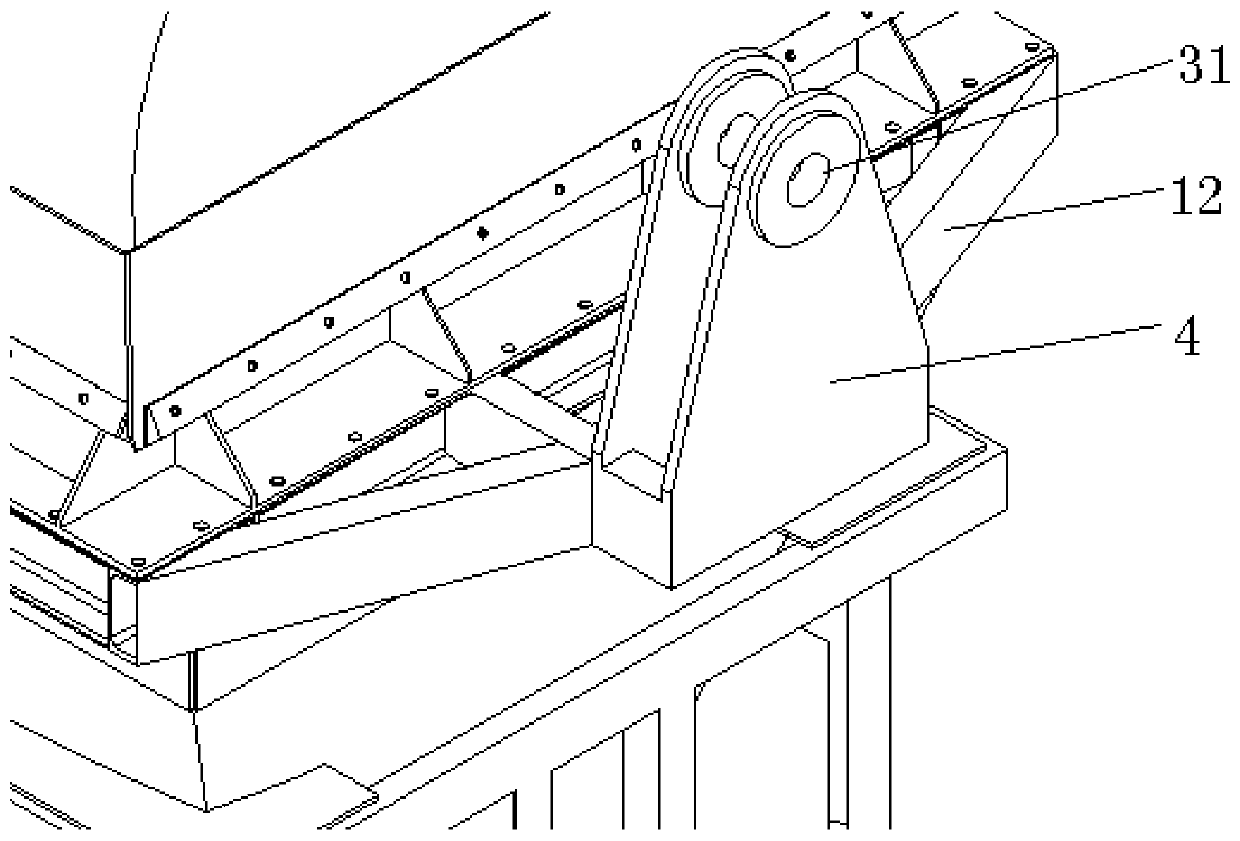

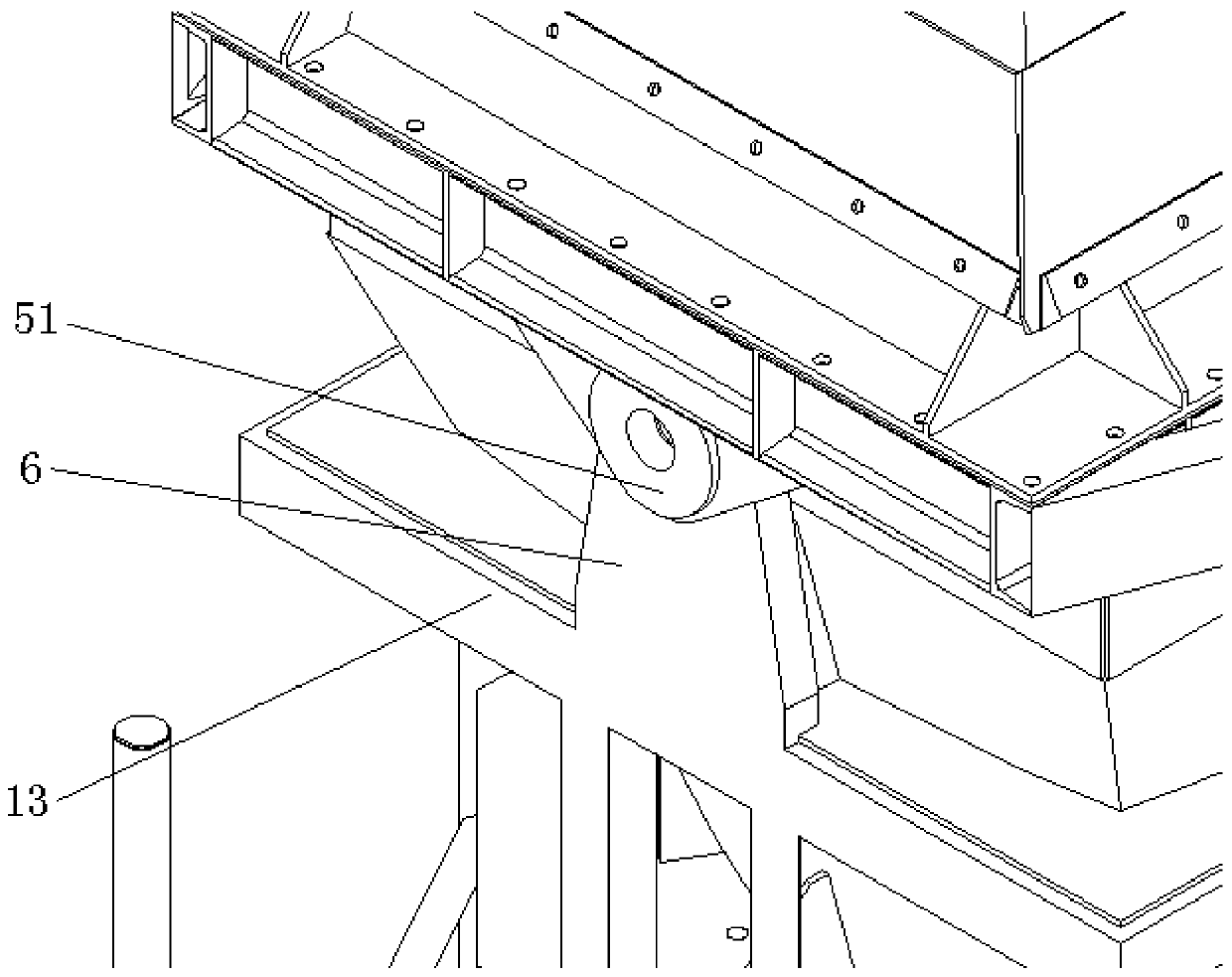

[0046] This embodiment provides a chute, such as figure 1 As shown, it includes a body, a first transition hopper 2 , a second transition hopper 7 , a first hinge 3 , and a second hinge 5 .

[0047] There is an anti-collision protection bar 8 outside the body. In this embodiment, the body includes the first chute section 9 and the second chute section 11 from top to bottom. The first chute section 9 and the second chute section 11 The connection is detachable. In other alternative embodiments, the number of chute sections is determined according to actual needs, and may include three chute sections or only one chute section. The anti-collision protection bar 8 includes a plurality of vertical bars arranged at intervals outside the body, each vertical bar is connected outside the body by a connecting rod, and a plurality of vertical pin shafts are arranged outside the body, and springs are connected on the pin shafts. When the anti-collision protection bar 8 hits an obstacle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com