Production method of fougere-flavor liquor

A Fuya-flavor type and production method technology, applied in the production field of Fuya-flavor liquor, can solve the problems of increasing market demand for compound-flavor liquor and separation of taste sensations, and achieve benefits for reproduction and survival, and enrich flavor substances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

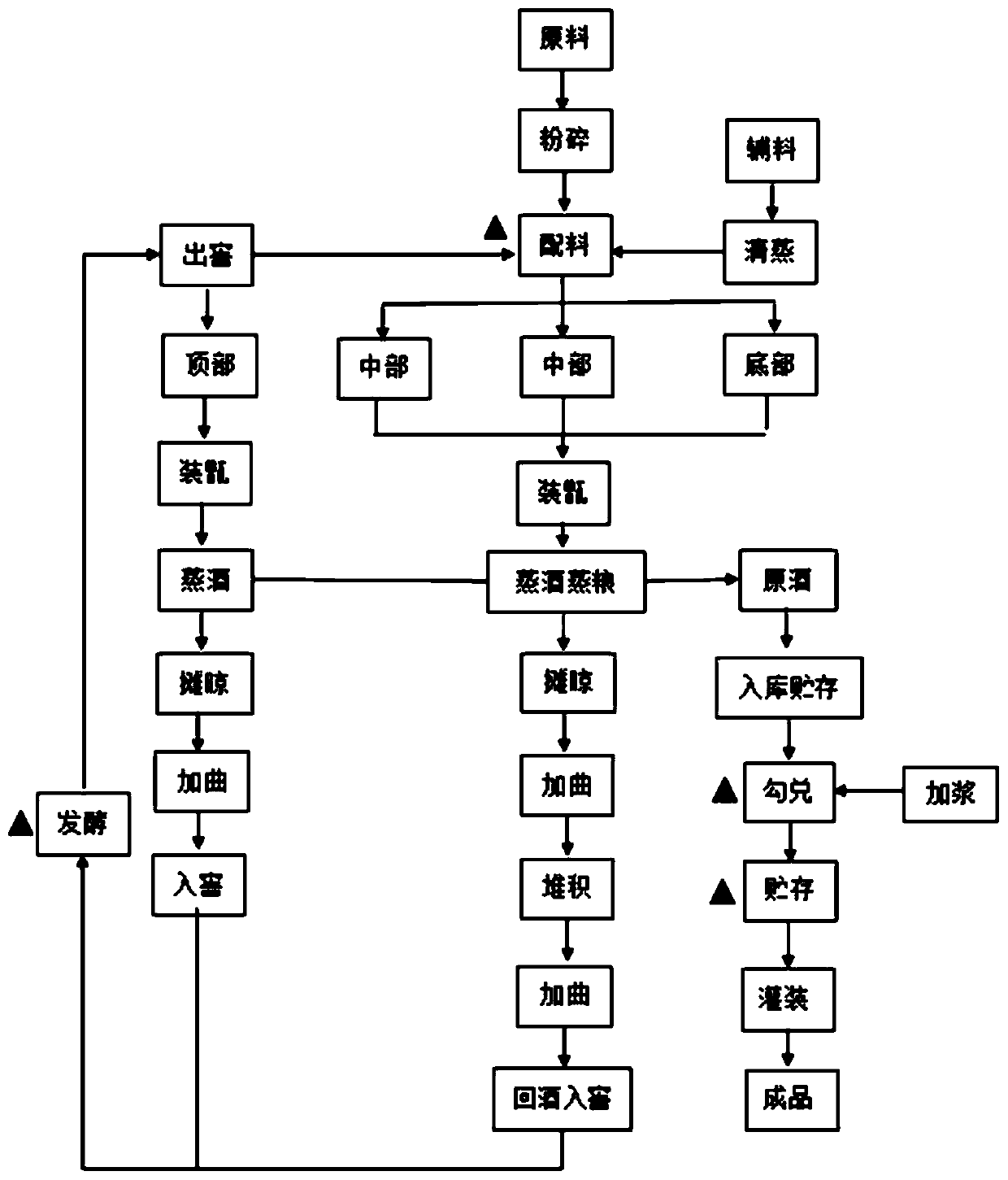

[0055] This embodiment provides a kind of production method of Fuya-flavor liquor, its technological process is as attached figure 1 As shown, the cellar pond that adopts is the cellar pond in embodiment 1B, specifically comprises the following steps:

[0056] (1) Processing of raw and auxiliary materials: sorghum, glutinous sorghum, corn, and wheat are crushed into 4-6-8 petals without whole grains. 80% pass through a 3mm aperture sieve, the rice husk must be steamed before use, and steamed for about 30 minutes;

[0057] (2) Leaving the cellar: first clean up the sanitation around the cellar pool, uncover the plastic sheeting, remove the mud from the cellar skin, and transport it to the mud for later use. Store separately, and cover the surface with a layer of rice husk to reduce the volatilization of wine;

[0058] (3) Ingredients: In terms of the ratio of raw materials, the distribution is accurate and strictly controlled. The proportion of raw materials is 36,000 parts o...

Embodiment 1B

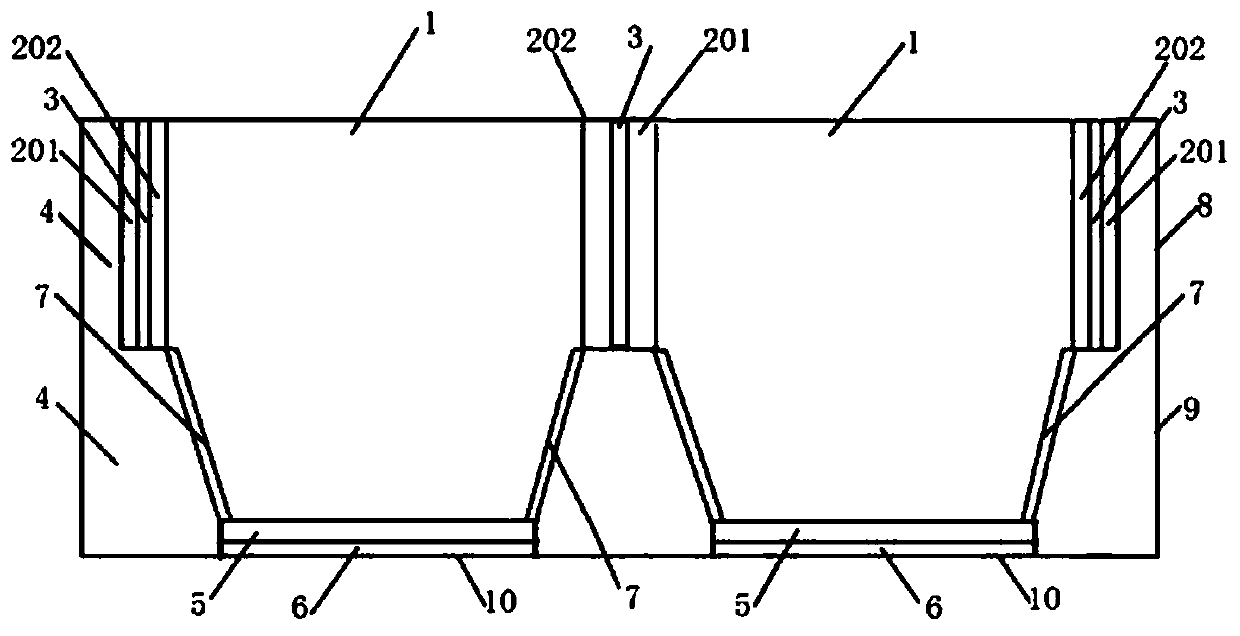

[0083] The Fuya-flavor liquor fermentation cellar used in the embodiment 1A has the following structure:

[0084] The cross section of the cellar 1 is roughly rectangular in cross section, and the cellar 1 is surrounded by the wall of the cellar and the bottom 10 of the cellar;

[0085] The cellar wall is composed of an upper cellar wall 8 located at the upper part of the cellar wall and a lower cellar wall 9 located at the lower part of the cellar wall;

[0086] The wall of the upper cellar from outside to inside is earth wall layer 4, first brick wall 201, anti-seepage layer 3 made of concrete, and second brick wall 202 (the first brick wall adjacent to the cellar); the anti-seepage layer The cement used in the concrete is C35 acid-resistant cement.

[0087] From the outside to the inside of the lower cellar, the wall of the cellar is the earth wall layer 4 and the first Fuya fragrance artificial cellar mud layer 7;

[0088] From bottom to top, the bottom of the cellar is ...

Embodiment 2

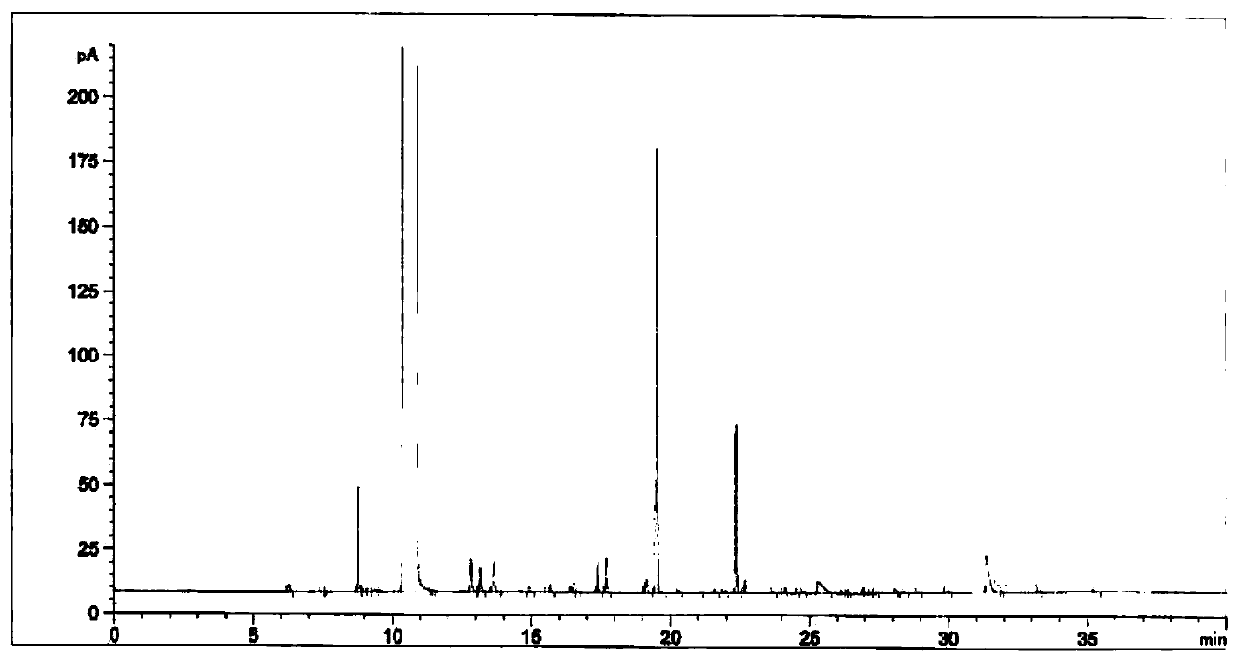

[0099] In order to prepare wine with better quality, the inventor has done a lot of experiments, some of which are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com