A kind of preparation method of phase change fiber

A phase change fiber, mass fraction technology, applied in the directions of microsphere preparation, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of large fiber diameter, poor softness and comfort, slow thermal response speed, etc. The effect of uniform layer thickness, good softness and fast comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

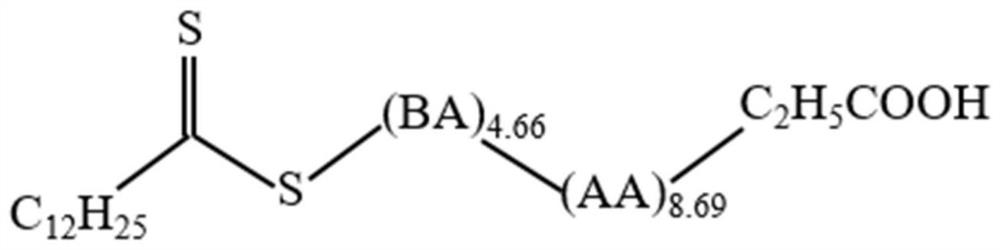

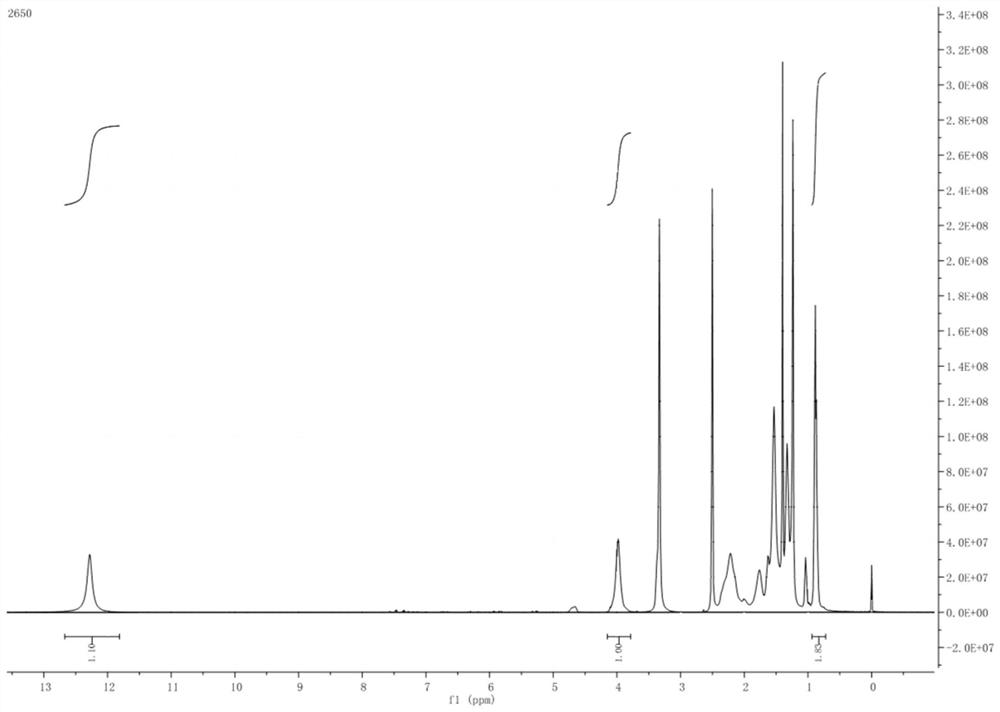

[0060] The first step: with 0.05 parts by mass of (AA 8.69 -co-nBA 4.66 ) The random copolymer is dissolved in 70 parts by mass of deionized water, stirred and dissolved;

[0061] The second step: mix the AIBN of 0.1 mass parts, the n-octadecane of 13.4 mass parts, the styrene of 5.03 mass parts, the divinylbenzene of 2.09 mass parts, stir and dissolve;

[0062] Step 3: Mix the water phase and the oil phase, stir and pre-emulsify for 30 minutes to form a coarse emulsion. Treat with a shearing device for 30 minutes to obtain a fine emulsion;

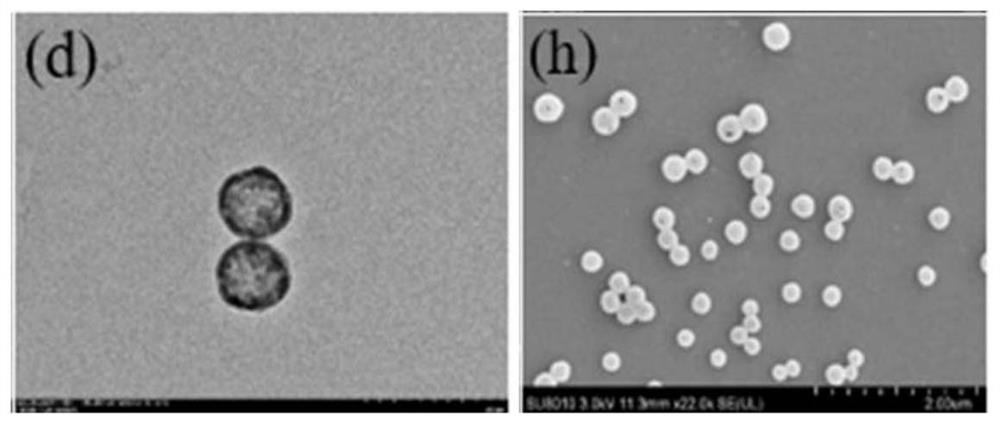

[0063] Step 4: add 0.07 parts by mass of amphiphilic macromolecular RAFT emulsifier, pass in an inert gas for 30 minutes, heat up to 70°C, and react for 10 hours to obtain an aqueous dispersion of submicron phase change capsules;

[0064] Step 5: Put 1 mass part of polyvinyl alcohol in 5.67 mass parts of dispersion medium, raise the temperature to 90°C, and stir for 2 hours to obtain spinning stock solution;

[0065] Step 6: Mix 1.87 ...

Embodiment 2

[0069] The first step: 0.5 parts by mass of (AA 100 -co-nBA 100 ) The random copolymer is dissolved in 400 parts by mass of deionized water, stirred and dissolved;

[0070] The second step: mix the AIBN of 0.5 mass parts, the n-octadecane of 200 mass parts, the styrene of 80 mass parts, the divinylbenzene of 20 mass parts, stir and dissolve;

[0071] Step 3: Mix the water phase and the oil phase, stir and pre-emulsify for 30 minutes to form a coarse emulsion. Treat with a shearing device for 30 minutes to obtain a fine emulsion;

[0072] Step 4: Add 0.2 parts by mass of amphiphilic macromolecular RAFT emulsifier, pass in an inert gas for 5 minutes, heat up to 60° C., and react for 12 hours to obtain an aqueous dispersion of submicron phase-change capsules.

Embodiment 3

[0074] The first step: 0.01 parts by mass of (AA 5 -co-nBA 5 ) The random copolymer is dissolved in 40 parts by mass of deionized water, stirred and dissolved;

[0075] Step 2: Mix 0.01 parts by mass of AIBN, 5 parts by mass of n-octadecane, and 1 part by mass of styrene, stir and dissolve;

[0076] Step 3: Mix the water phase and the oil phase, stir and pre-emulsify for 5 minutes to form a coarse emulsion. Treat with a shearing device for 5 minutes to obtain a fine emulsion;

[0077] Step 4: add 0.01 parts by mass of amphiphilic macromolecular RAFT emulsifier, pass in an inert gas for 30 minutes, heat up to 95° C., and react for 6 hours to obtain an aqueous dispersion of submicron phase-change capsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| enthalpy of fusion | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com