A kind of reprocessing method of positive electrode active material of waste lithium ion battery

A cathode active material, lithium-ion battery technology, applied in battery electrodes, battery recycling, waste collector recycling, etc., can solve problems such as component loss and solvent separation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

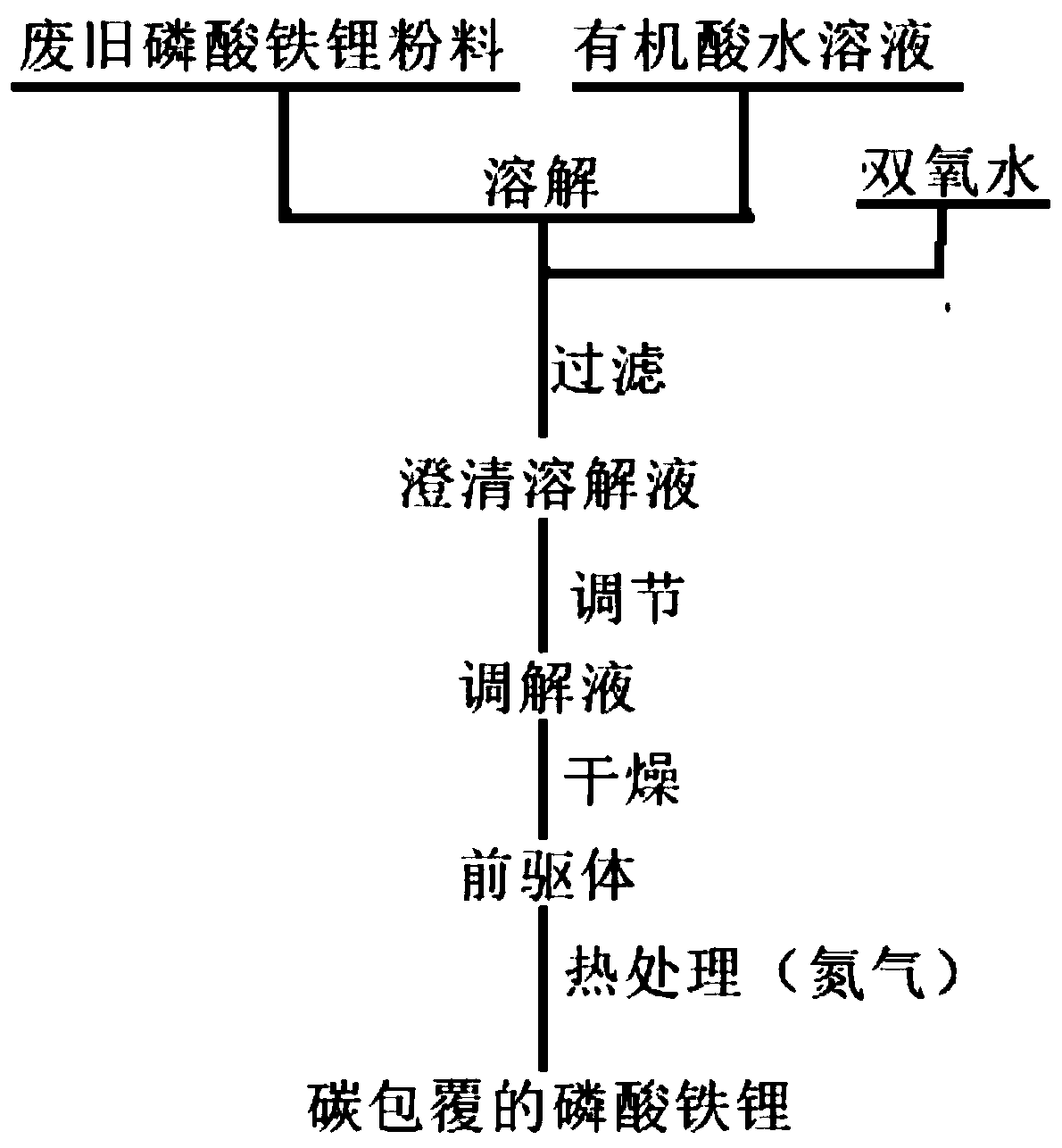

[0031] Add 50 g of the separated waste lithium iron phosphate powder into the mixed organic acid solution, heat and stir to dissolve it, the organic acid solution is acetic acid, succinic acid and citric acid, the addition amount is 1 liter, and the temperature for heating and dissolving is 60°C. The solid-to-liquid ratio of the waste lithium iron phosphate powder and the organic acid solution is 50 g / liter, and the reaction time for heating and dissolving is 0.5 hours; 1% of the mass, after filtering to obtain a clarified solution, adjust the content of lithium source, iron source, and phosphorus source in the clarified solution, so that the molar ratio of lithium source, iron source, and phosphorus source is 1:1:1, and obtain mediation solution; concentrating the mediation solution, and then spray-drying the concentrated mediation solution to obtain a precursor of lithium iron phosphate; performing heat treatment on the precursor under nitrogen protection, the temperature of ...

Embodiment 2

[0033] Add 50 g of the separated waste lithium iron phosphate powder into the mixed organic acid solution, heat and stir to dissolve it, the mixed organic acid solution is ammonium formate, citric acid, and oxalic acid, the amount added is 250 ml, and the temperature for heating and dissolving is 60°C. The solid-to-liquid ratio of the waste lithium iron phosphate powder and the organic acid solution is 200 g / liter, and the reaction time for heating and dissolving is 3 hours; 8% of the mass, after filtering, obtain a clarified solution, adjust the content of lithium source, iron source, and phosphorus source in the clarified solution, so that the molar ratio of lithium source, iron source, and phosphorus source is 1.3:1:1, and obtain mediation solution; concentrating the mediation solution, and then spray-drying the concentrated mediation solution to obtain a precursor of lithium iron phosphate; performing heat treatment on the precursor under nitrogen protection, the temperatur...

Embodiment 3

[0035] Add 50 g of the separated waste lithium iron phosphate powder into the mixed organic acid solution, heat and stir to dissolve it, the organic acid solution is ammonium acetate, oxalic acid, citric acid, the amount added is 500 ml, and the temperature for heating and dissolving is 90°C. The solid-to-liquid ratio of the waste lithium iron phosphate powder and the organic acid solution is 100 g / liter, and the reaction time for heating and dissolving is 1.5 hours; 0.5% of the mass, after filtering to obtain a clarified solution, adjust the content of lithium source, iron source, and phosphorus source in the clarified solution, so that the molar ratio of lithium source, iron source, and phosphorus source is 1.2:1:1, and obtain mediation solution; concentrating the mediation solution, and then spray-drying the concentrated mediation solution to obtain a precursor of lithium iron phosphate; performing heat treatment on the precursor under nitrogen protection, the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com