Stepped combined fabric and production method thereof

A production method and stepped technology, applied in the direction of fabrics, multi-strand fabrics, textiles, etc., can solve the problems of lack of three-dimensional sense and inability to meet differentiation, and achieve the effect of reducing weft breakage and adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

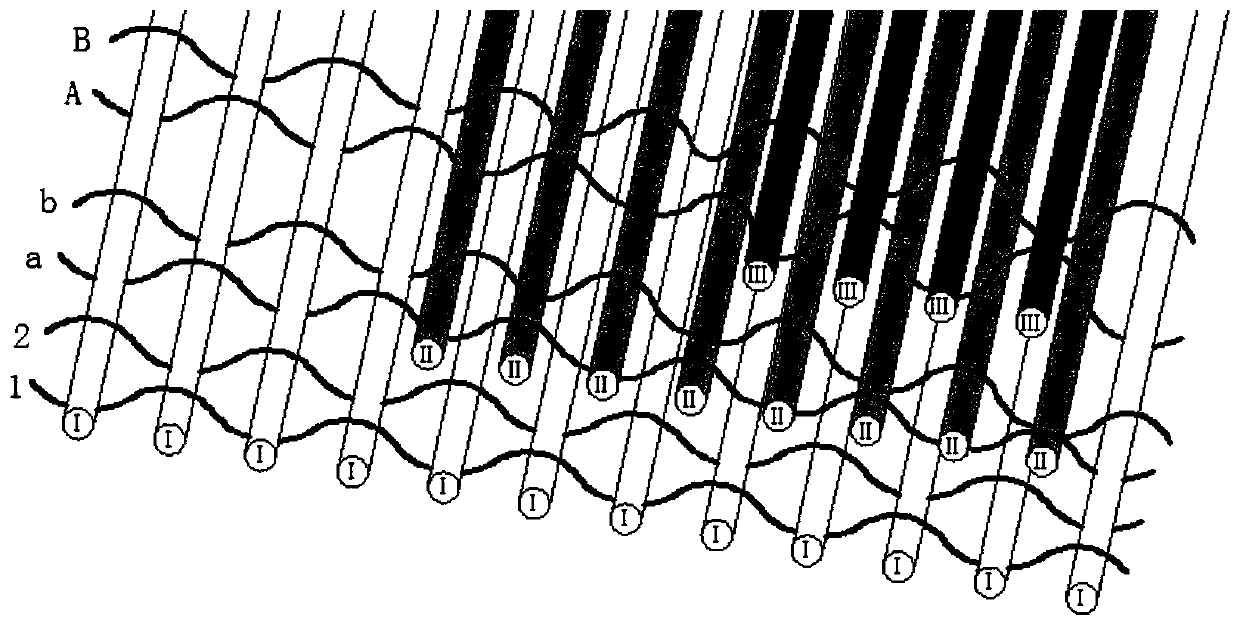

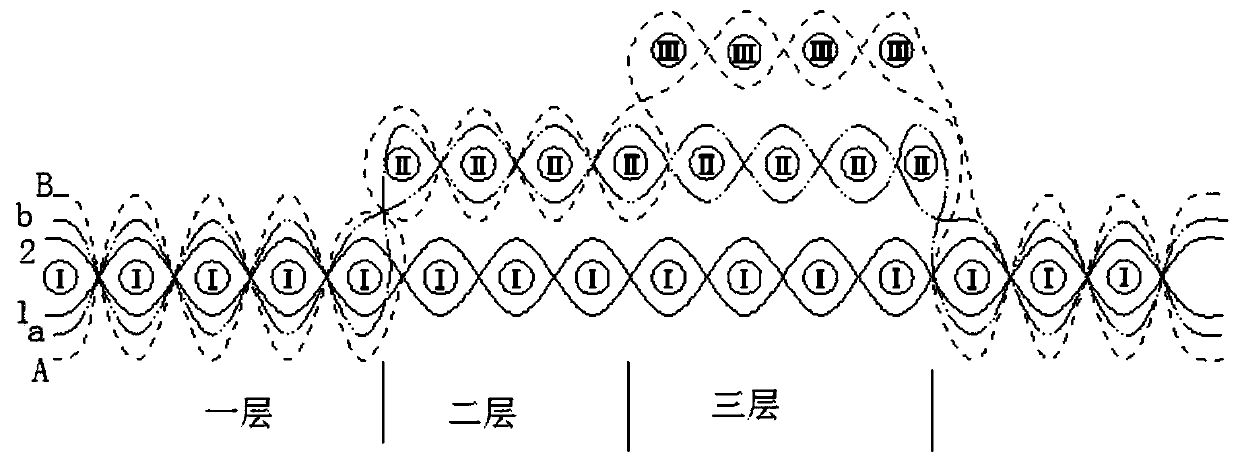

[0029] Such as figure 1 , in the weft direction from left to right, that is, the entire area from the left selvedge through the fabric body to the right selvedge (as shown in area I), warp yarns 1 and 2 of the first layer I are interwoven with weft yarns 1 and 2 The fabric forms the bottom layer of the fabric and is also the base layer of the fabric structure. The second layer II and the third layer III are directly or indirectly interwoven with the first layer, that is, the first layer also plays a role of consolidation.

[0030] Such as figure 1 , the weft yarns a and b of the second layer of fabric II are first interwoven with the warp yarns 1 and 2 of the first layer to form the first layer of the fabric, and in the second layer area (such as figure 1 As shown), the warp yarn is divided into two layers of warp yarn system, and the lower layer is the warp yarn of the first layer of fabric. The upper layer is the warp yarn of the second layer of fabric. The weft yarns a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com