Building shear wall formwork supporting system

A formwork support and shear wall technology, which is applied in construction, building structure, and on-site preparation of building components, etc., can solve problems affecting the quality of shear wall pouring, gaps in formwork joint positions, and inconvenient formwork joint positioning, etc. Achieve the effect of facilitating construction work, improving accuracy and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

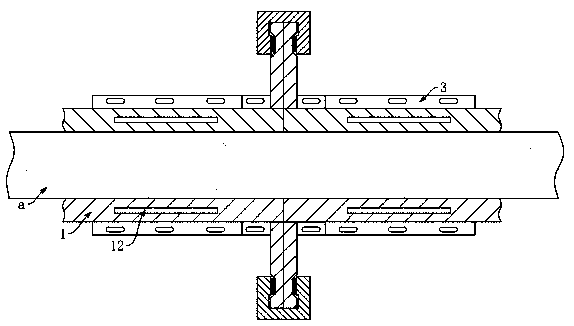

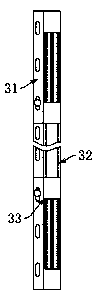

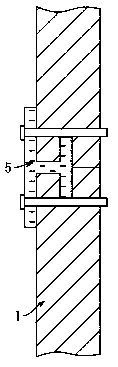

[0041] After the anchor bar of the shear wall is fixed, splicing formwork 1 is set up on both sides of the anchor bar, that is, on both sides of the precast wall a. First, the second connecting member 3 is placed on the ground, that is, according to the preset Lay the connecting rods on the ground, and adjust the length of the connecting rods to adapt to the length of the wall a. First, use anchor bolts to fix the ends of the connecting rods on the ground, and then adjust the first connecting rods 31 and the second connecting rods. The relative position of bar 32 makes each first connecting rod 31, the second connecting rod 32 expose the same length, and further use bolts to pass through the bolt holes of the first connecting rod 31, the second connecting rod 32 to the first connecting rod 31, The relative position of the second connecting rod 32 is fixed, and the adjacent connecting rods are connected by the connecting structure 4. The connection angle between the connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com