A Coal Caving System and Method for Reducing Top Coal Loss in Fully Mechanized Caving Faces

A fully mechanized caving face and working face technology, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems that do not take into account the shape of the top-coal discharge body and the characteristics of the interface between coal and rock, so as to achieve balanced coal caving, The effect of increasing the discharge degree and increasing the recovery rate of the top coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

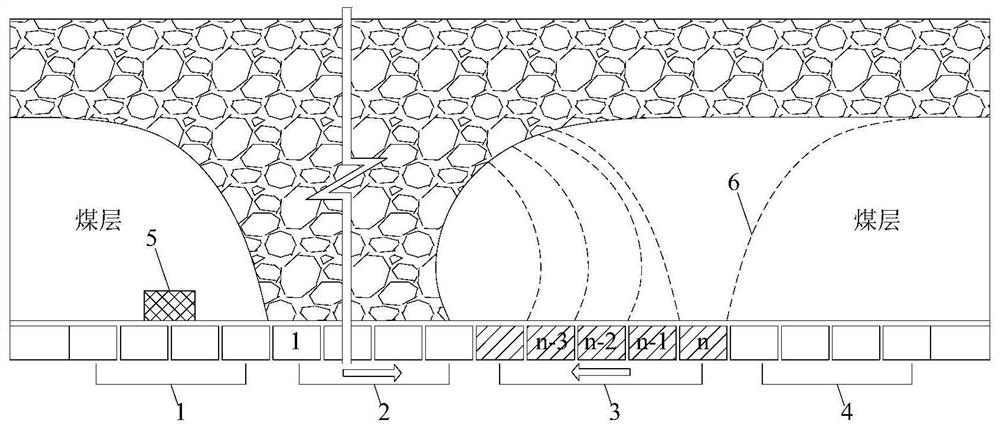

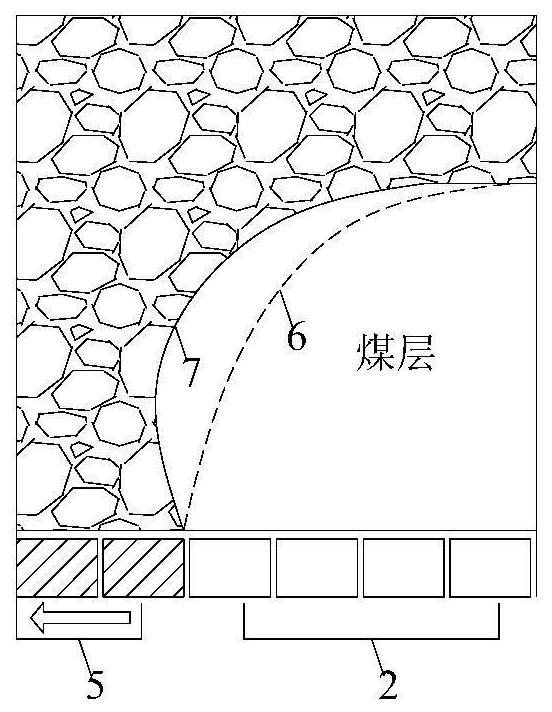

[0067] The present invention provides a coal-drawing system and method for reducing the loss of top coal at the top of a fully-mechanized caving face. According to the geological conditions of a certain mine, the operation steps of the coal-drawing process are as follows:

[0068] a. Rationally arrange the top-coal caving mining face, supporting mining, transportation and support equipment;

[0069] b. From the upper end to the lower end, number the coal discharge brackets, numbered 1, 2, ..., 10;

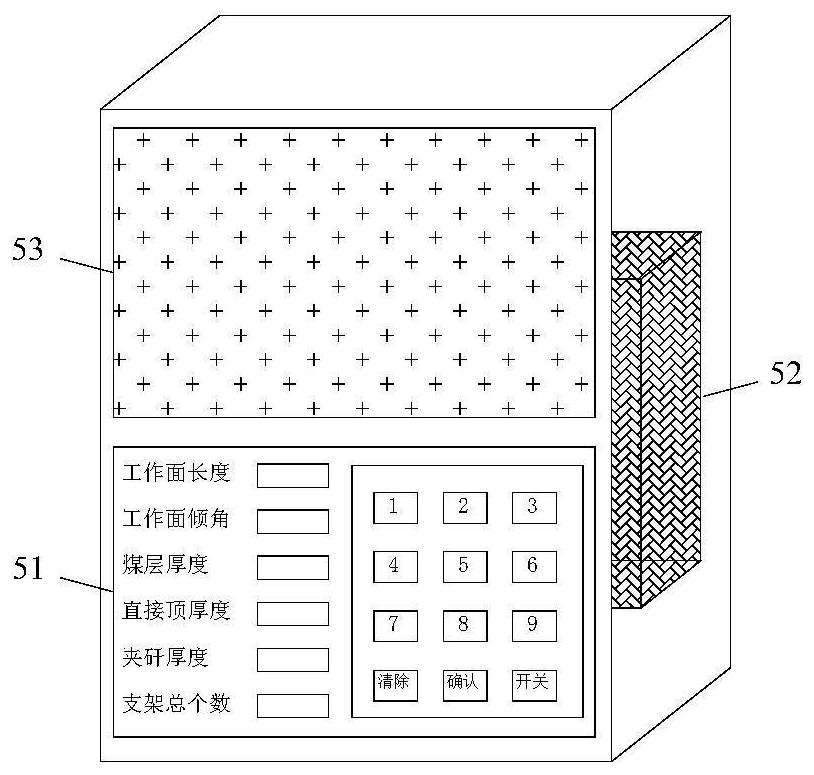

[0070] c. Open the analysis system 5 of the reverse sequence coal discharge section at the end, and manually input the basic information of the working face;

[0071] d, according to the information displayed by the information output module 53, it is determined that the length of the reverse sequence coal discharge section 3 is 6cm and the predicted value of the top coal recovery rate of the working face is 83%;

[0072] e. Start the coal discharge operation on the working face. ...

Embodiment 2

[0076] According to the geological conditions of a certain mine, the influence of the coal-drawing method on the top-coal discharge is analyzed.

[0077] On the same working face, the coal is discharged in two ways, the normal positive sequence and the above-mentioned method of reducing coal loss at the end of the fully mechanized caving face. The measured coal discharge of this coal discharge system is 26.89% higher than that of the normal positive sequence. , the loss of overhead coal at the lower end was reduced by 13.98%.

[0078] It can be seen from the above examples that the method provided by the present invention has the characteristics of less loss of top coal and high mining efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com