Large-angle and high-efficiency ball-cage type constant-velocity universal joint with eight steel balls

A constant velocity joint, high-efficiency technology, applied in the field of auto parts, can solve the problems of strength and durability not meeting design requirements, unable to meet the requirements of turning use, reducing durability and transmission efficiency, etc., to achieve strength and durability. The effect of maintaining sex, compact structure, avoiding excessive squeezing and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments.

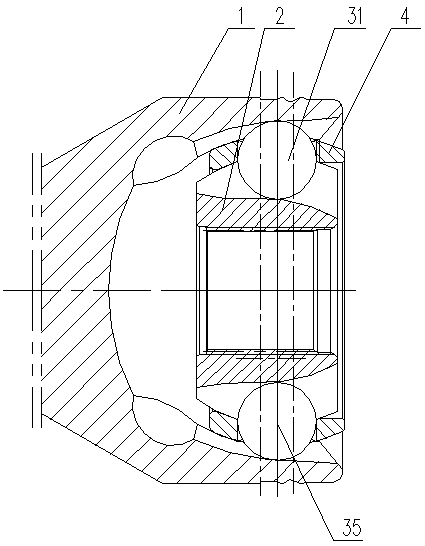

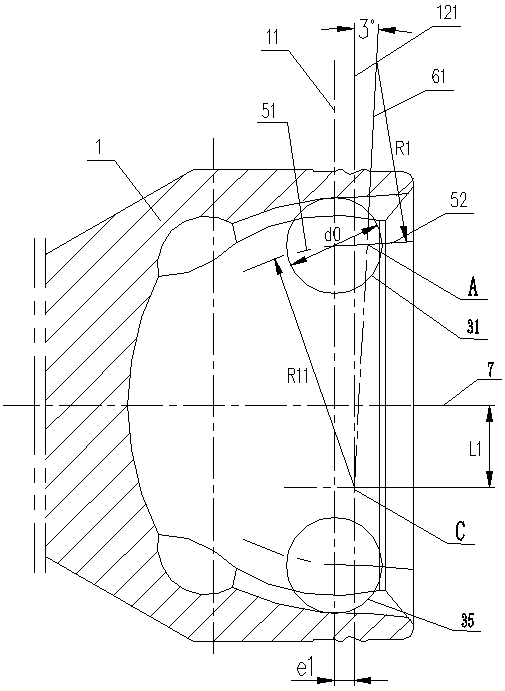

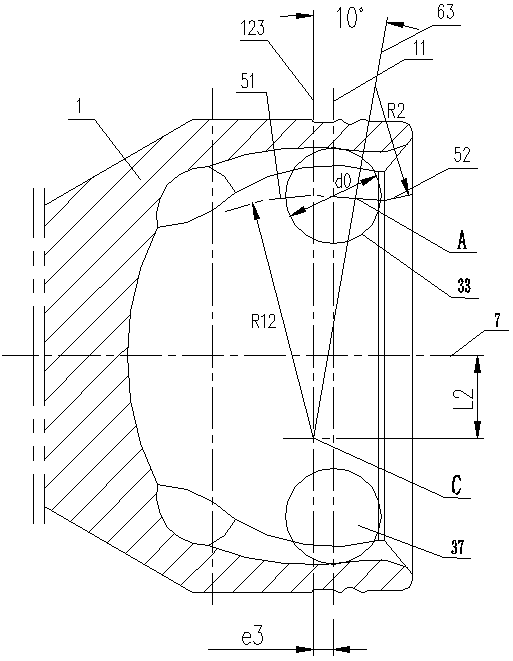

[0028] like Figure 1 to Figure 11As shown, this embodiment includes a bell-shaped shell 1 with an inner cavity, a star sleeve 2 located in the inner cavity of the bell-shaped shell 1, an annular cage 4 and 8 steel balls: steel ball I31, steel ball II32, steel ball Ball III33, steel ball IV34, steel ball V35, steel ball VI36, steel ball VII37 and steel ball VIII38. Between the raceway of the star-shaped sleeve 2 and the raceway of the bell-shaped housing 1 are 8 steel balls kept in an angle bisector by an annular cage 4 with eight windows evenly distributed, and the raceway fit is a transition fit. The inner wall of the bell-shaped housing 1 and the inner wall of the annular cage 4 form a set of spherical pairs, the inner wall of the annular cage 4 and the outer wall of the star sleeve 2 form another set of spherical pairs, and the two sets of spherical pairs are clearance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com