Combined wheel and lighter using same

A combined wheel and lighter technology, which is applied in the direction of igniter with fuel, combustion ignition, combustion method, etc., can solve the problems of affecting the stability of use, loss of flaps to identify combined wheels, and reduced production efficiency, so as to reduce the rework of waste products Effects of workload, improvement of recognition accuracy, and improvement of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

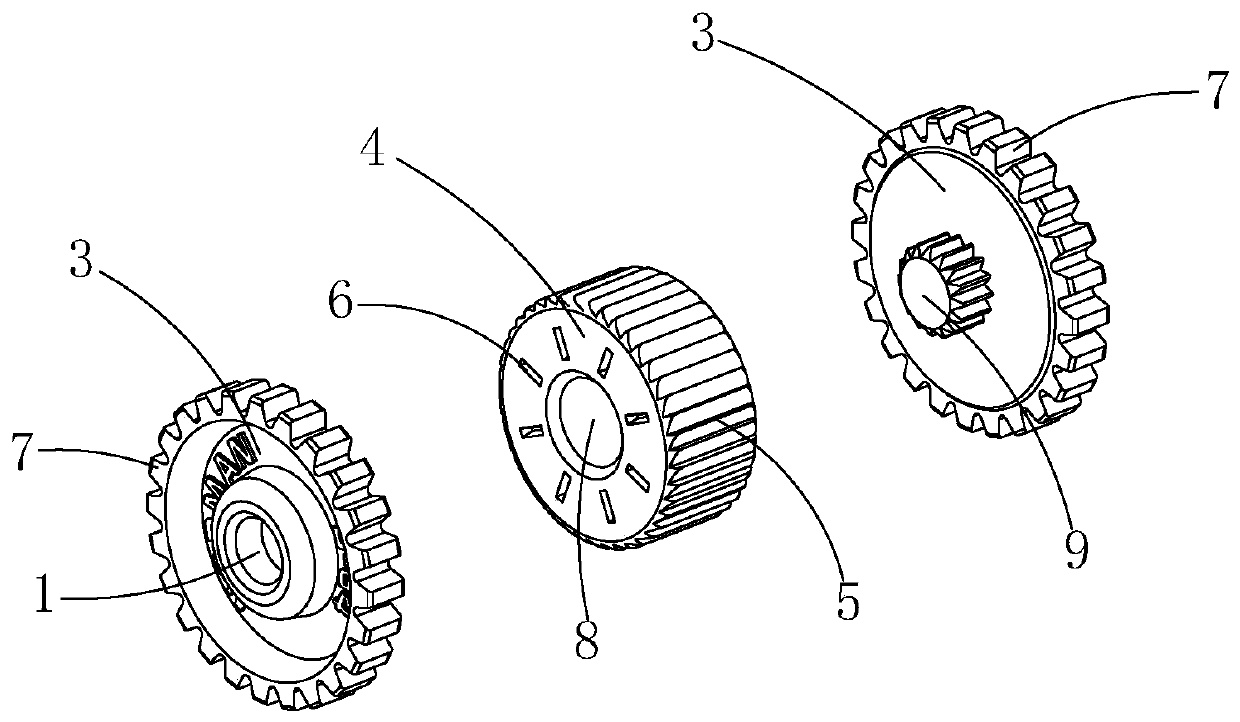

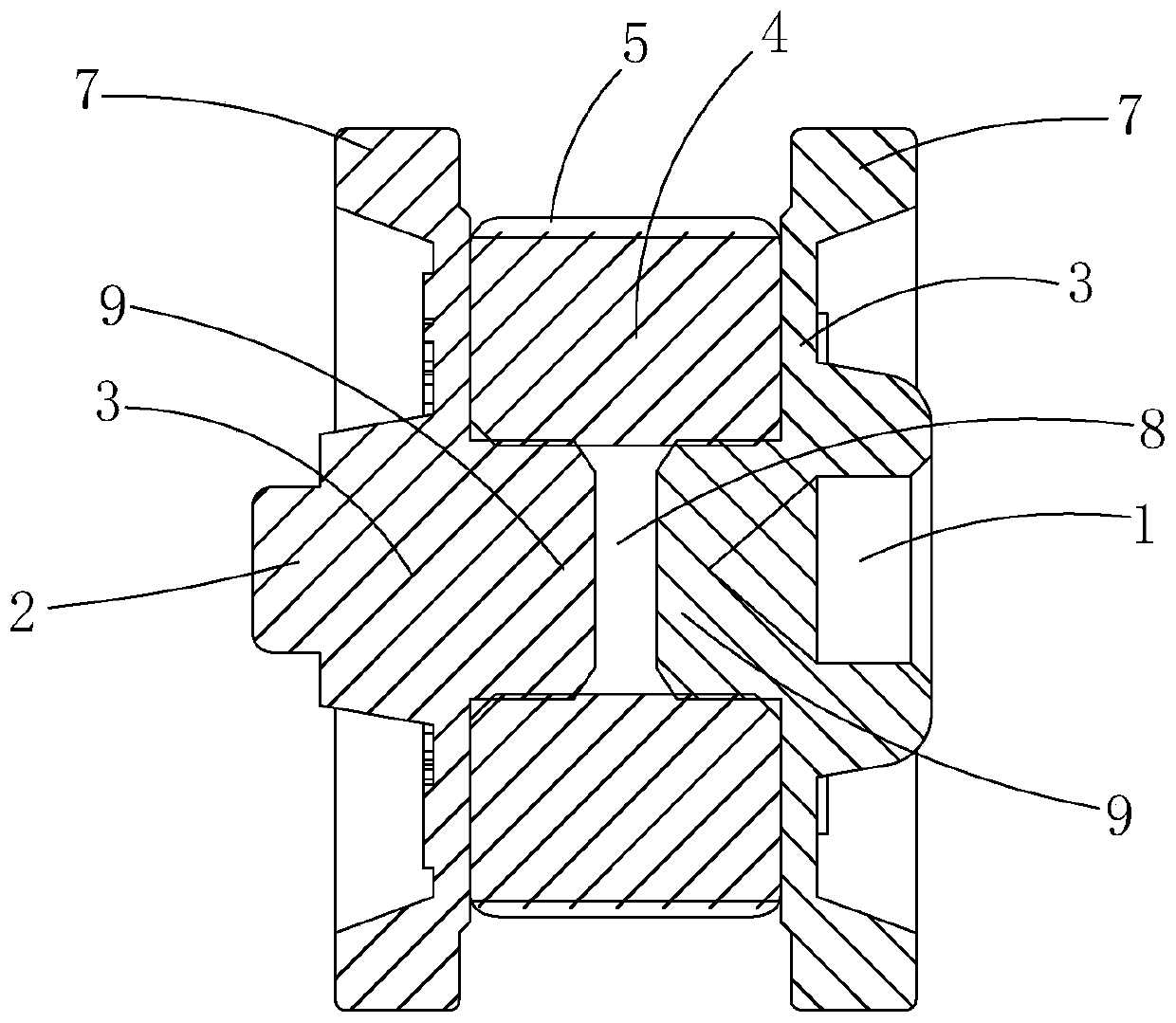

[0031] This embodiment provides a combination wheel and a lighter using it.

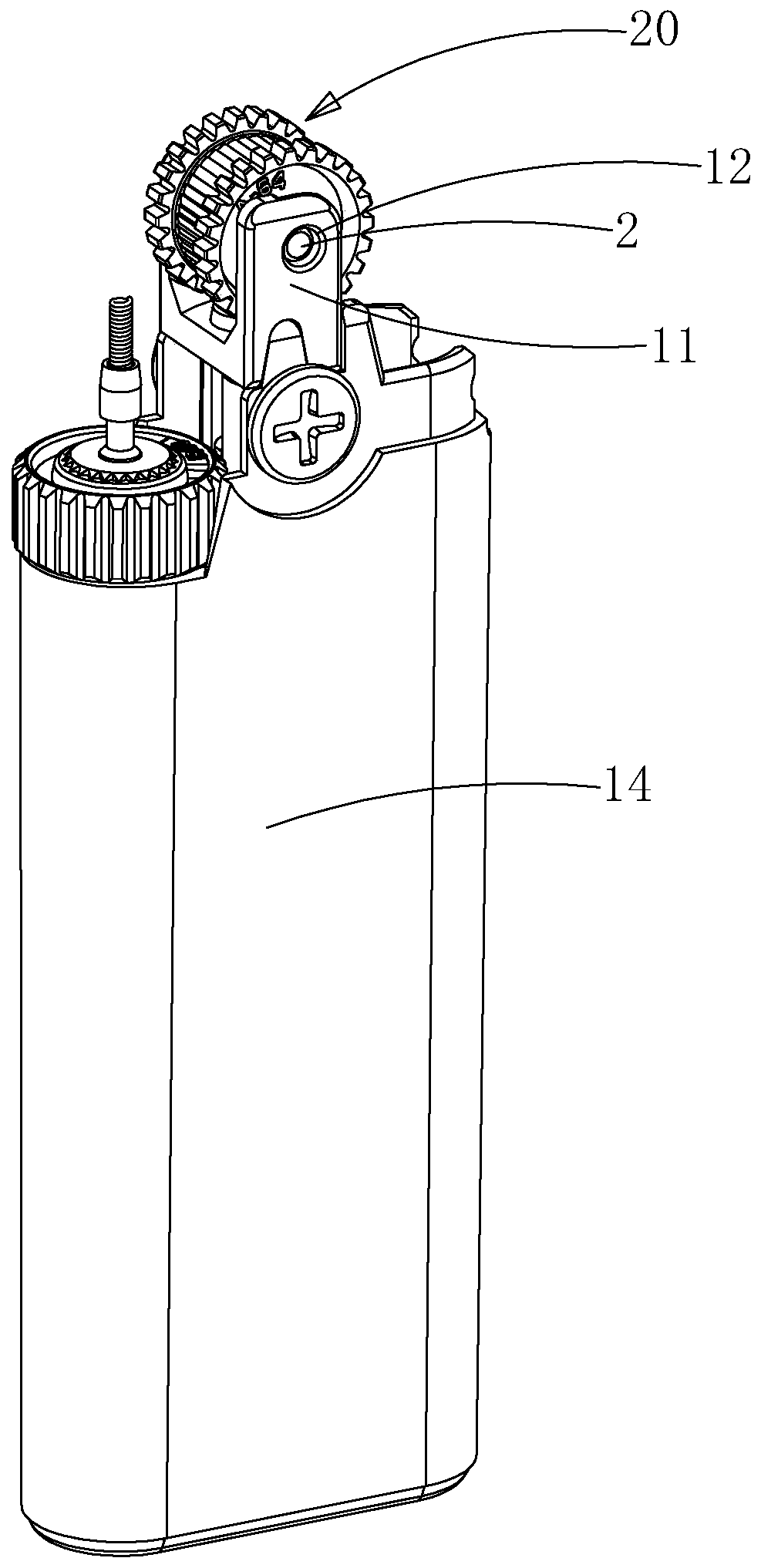

[0032] Such as figure 1 , 3 As shown in , 4, a lighter is composed of a casing, a combination wheel rotatably connected to the casing, and a flint 10 matched with the combination wheel. The casing is provided with a machine fork, and the machine fork includes Two oppositely arranged connectors 11, the opposite surfaces of the connectors 11 are respectively provided with an assembly hole 12 for the insertion and connection of the installation shaft 2 and an assembly shaft 13 for the sleeve connection of the installation hole 1. After the installation is in place, the combination The wheel is rotatably mounted on the fork, so that the knife edge 5 that rotates with the combined wheel scrapes and rubs against the flint 10 .

[0033] In this embodiment, a fuel chamber is provided in the casing, and an injection port is provided on the fuel chamber. The combination wheel rubs against the flint 10 to gen...

Embodiment 2

[0054] Compared with the first embodiment, this embodiment provides another lighter structure.

[0055] Such as Image 6 , 7 As shown, the casing is a split structure, including a body 14 and a machine fork 15, the top of the body 14 is provided with a socket 16, the bottom of the machine fork 15 is inserted into the socket 16, and the top forms a mechanism exposed to the socket 16. Fork, a fool-proof assembly is provided between the periphery of the hole 16 and the machine fork 15. After the combination wheel is installed in place, the knife edge 5 is set in a preset direction.

[0056] The top of the body 14 is provided with a socket 16 , and when installed, the bottom of the machine fork 15 is vertically inserted into the socket 16 so that the machine fork is exposed on the top of the body 14 . In order to prevent the machine fork 15 from being installed in reverse, the installation posture of the machine fork 15 is checked and corrected by setting the fool-proof componen...

Embodiment 3

[0063] Compared with the first embodiment, this embodiment provides another lighter structure.

[0064] In this embodiment, the casing is a split structure, including a body 14, a middle frame sleeved on the body 14, and a machine fork 15 arranged on the middle frame. The machine fork and the middle frame are of an integrated structure. During installation, the combination wheel is rotatably installed on the machine fork 15, and the machine fork 15 is assembled to the body 14 by the middle frame located below it, so that the combination wheel is affixed to the body 14 top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com