Installation tool for cyclone sleeve

A technology for installing tools and sleeves, which is applied in the direction of manufacturing tools, hand-held tools, workpiece clamping devices, etc., can solve the problems of low installation efficiency of cyclone sleeves, slow down operation efficiency, damage of cyclone sleeves, etc., and reduce rework The effect of reducing workload, improving installation quality, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

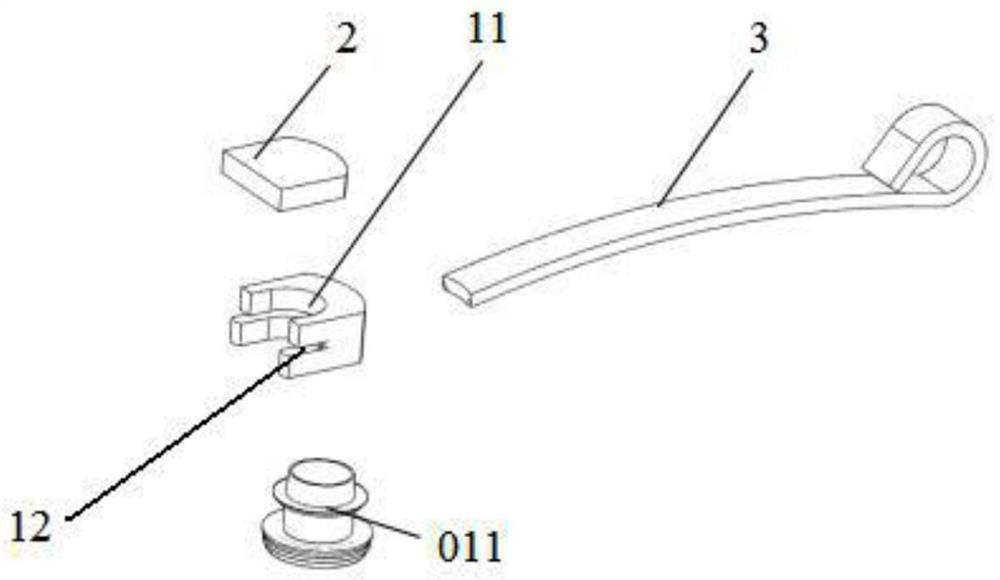

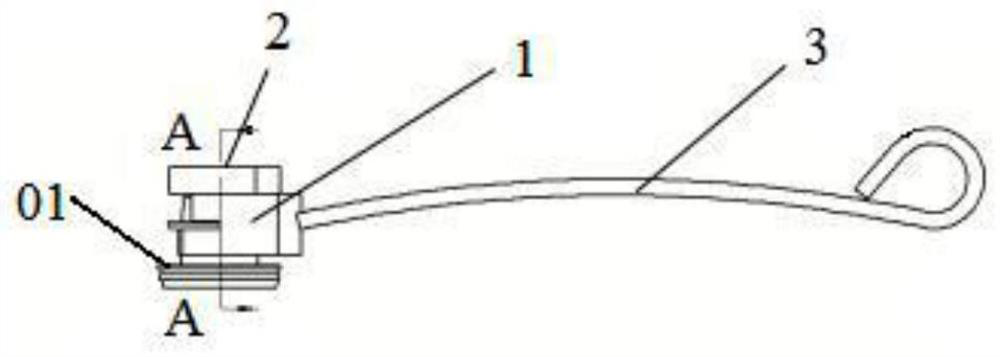

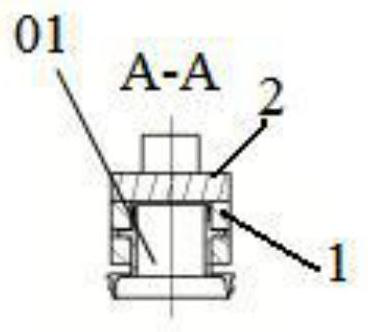

[0025] see Figure 1 ~ Figure 3 , an installation tool for a cyclone sleeve, including a clamping part 1 , a striking part 2 and a handle part 3 . The outer wall of the cyclone sleeve 01 is provided with a lapping piece 011 along the circumference, and the lapping piece 011 is specifically an annular lapping plate.

[0026] The clamping part 1 is provided with a slot 11 for vertically fixing the cyclone sleeve 01. The slot 11 is a U-shaped slot with an opening facing the horizontal side. The slot 11 is also a through-slot structure. The upper end and the lower end are all open, and a positioning groove 12 for clamping the overlapping plate is arranged on the side wall of the locking groove 11 along the horizontal direction. The positioning groove 12 is a U-shaped structure and the width matches the thickness of the overlapping plate design.

[0027] The beating part 2 is located directly above the card slot 11 and is fixedly connected to the upper end surface of the card slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com