Constructional engineering quality flatness detection device

A flatness detection and construction engineering technology, applied in the field of construction engineering, can solve the problems of low flatness accuracy, lack of floor, and inability to be close to the wall, so as to increase the detection area and improve the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

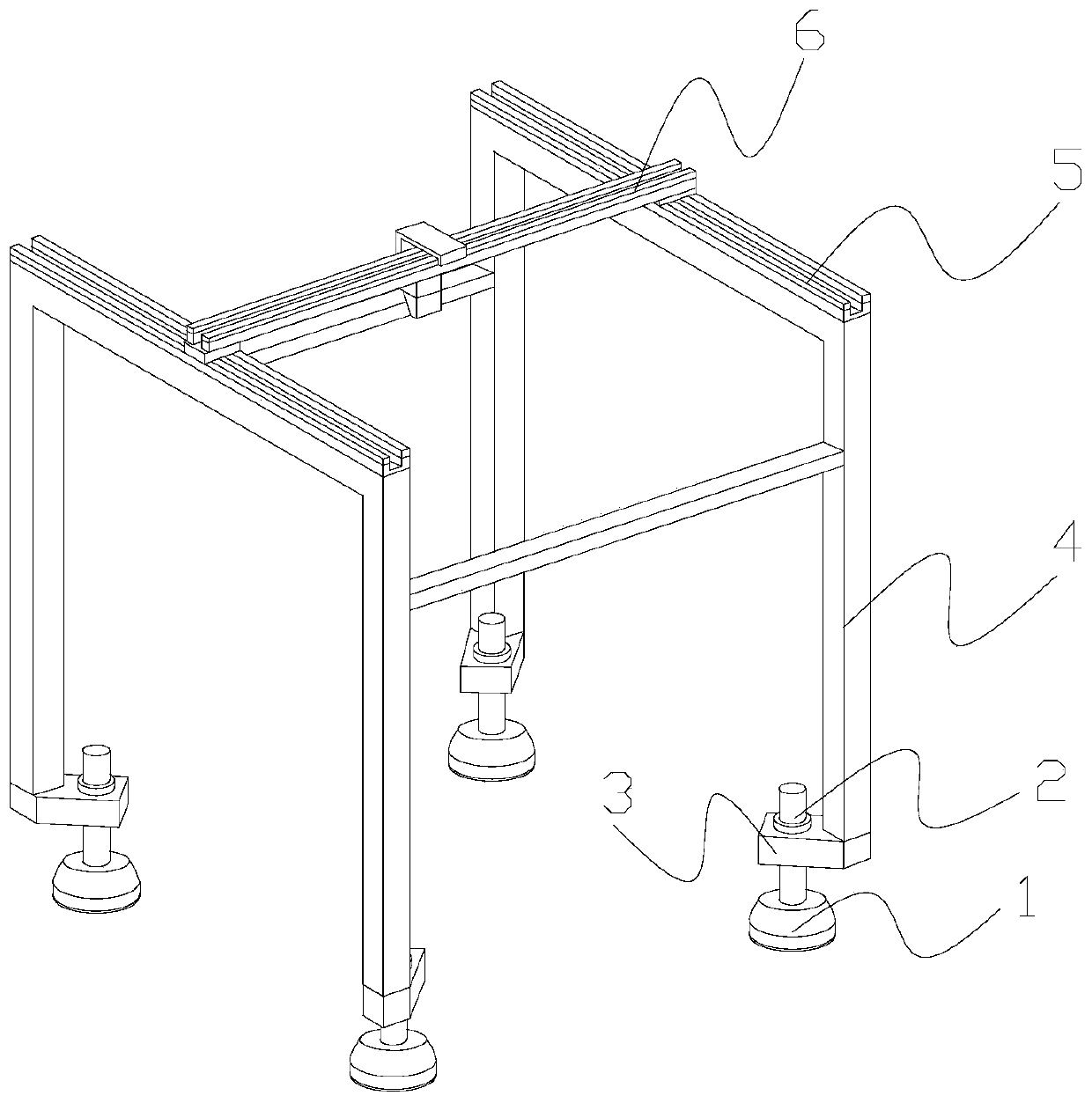

[0030] see Figure 1-Figure 11 , the specific embodiments of the present invention are as follows:

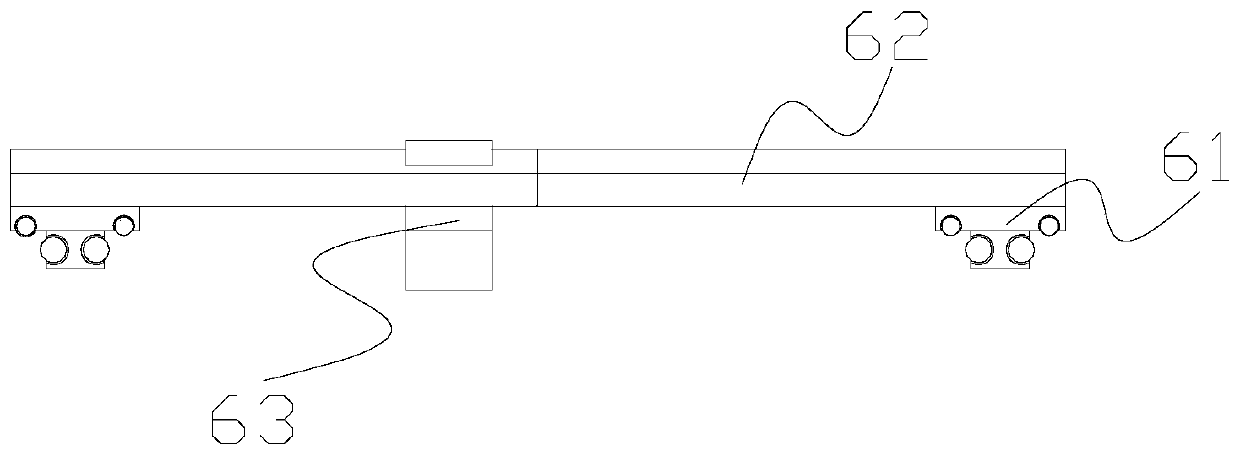

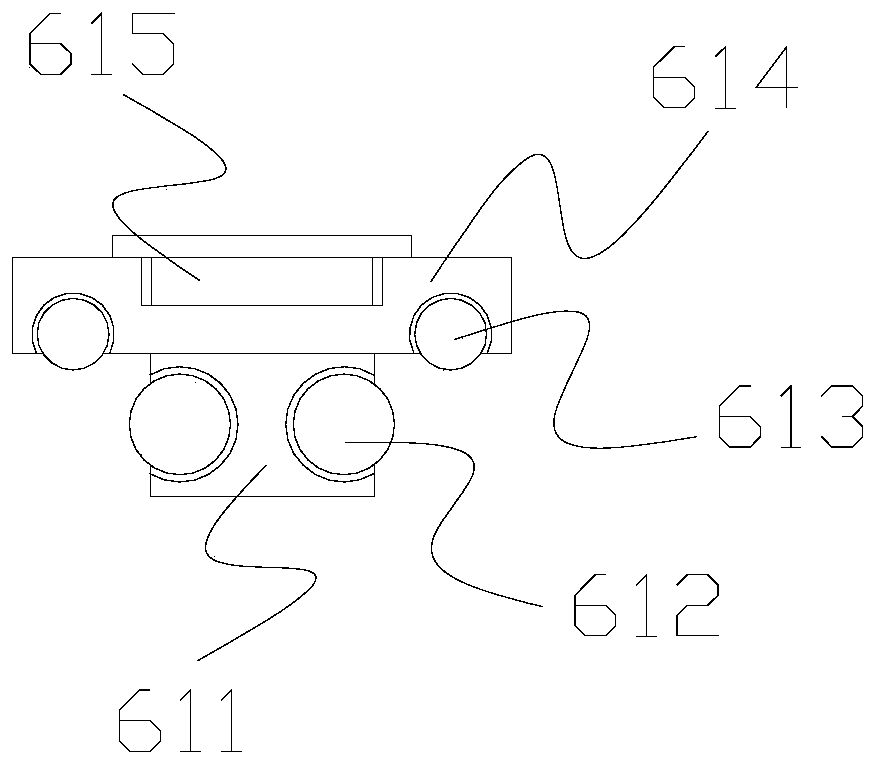

[0031] Its structure includes a foot 1, an adjustment rod 2, a support block 3, a support frame 4, a transverse rail 5, and an activity detection structure 6. The foot 1 is horizontally installed on the lower end of the adjustment rod 2 and is mechanically connected. The adjustment rod 2 runs through the The inner side of the support block 3 is threaded, the support block 3 is horizontally installed on the inner side of the lower end of the support frame 4 and welded, the transverse rail 5 is welded to the upper end of the support frame 4 and distributed on both sides, the activity detection structure 6 is installed between the horizontal rails 5 and adopts a flexible connection; the activity detection structure 6 includes a horizontal sliding structure 61, a longitudinal rail structure 62, and a movement detection structure 63, and the horizontal sliding structure 61 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com