A composite structure of indium tin oxide/vertical graphene photodetector and its preparation method

A photodetector, indium tin oxide technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of low responsivity, weak light absorption of single-layer graphene, etc., achieve multiple photocurrents, good light transmittance and Effects of charge transport properties, high light absorptivity, and photoresponsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

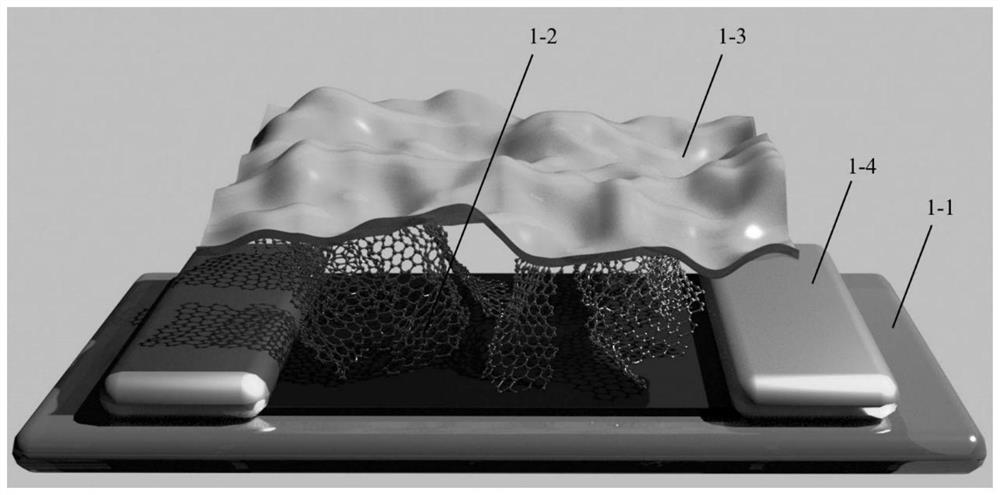

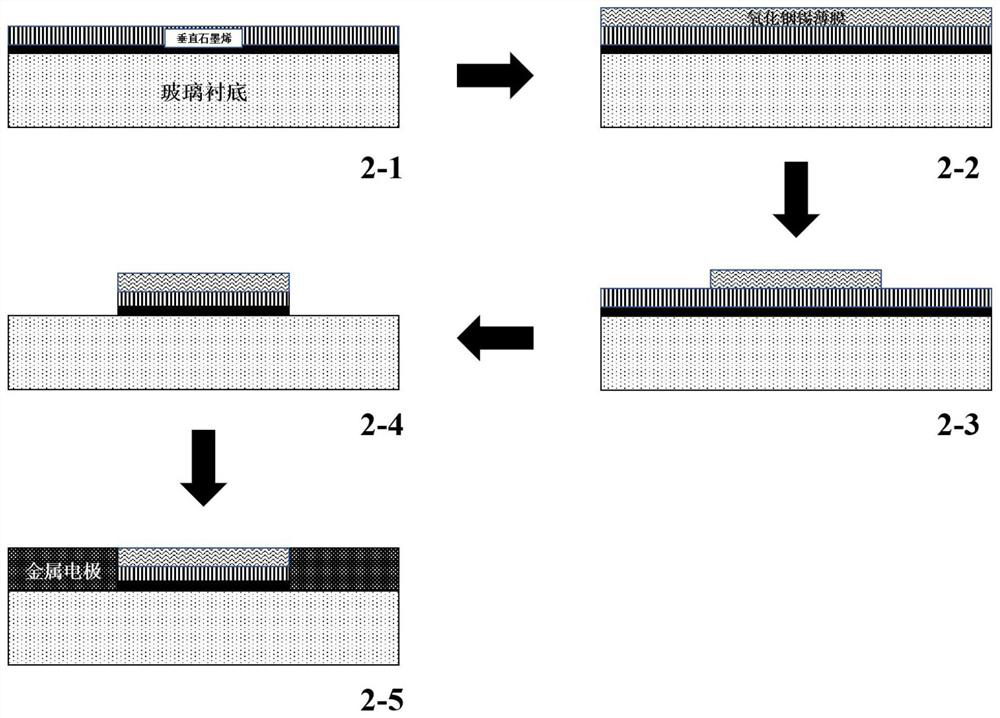

[0033] Embodiment 1: the preparation method of indium tin oxide / vertical graphene photodetector composite structure

[0034] Prepare indium tin oxide / vertical graphene photodetector composite structure, the preparation method step of the present invention is as follows:

[0035] (1) Directly grow vertical graphene on the glass substrate, the vertical graphene height is about 400nm (wherein the height of the buffer layer is much lower than the height of the graphene sheet, generally about 50nm), clean the vertical graphene sample: use acetone in turn solution, ethanol solution and deionized water to clean the vertical graphene sample;

[0036] (2) Preparation of indium tin oxide thin film: on the vertical graphene grown on the glass substrate, a 100nm indium tin oxide thin film was deposited using magnetron sputtering technology, and the deposition temperature was 100°C;

[0037](3) Etching the indium tin oxide thin film channel: use AZ5214 photoresist, adopt the positive phot...

Embodiment 2

[0041] Embodiment 2: the photocurrent test (ie comparative example) of vertical graphene photodetector (no indium tin oxide thin film)

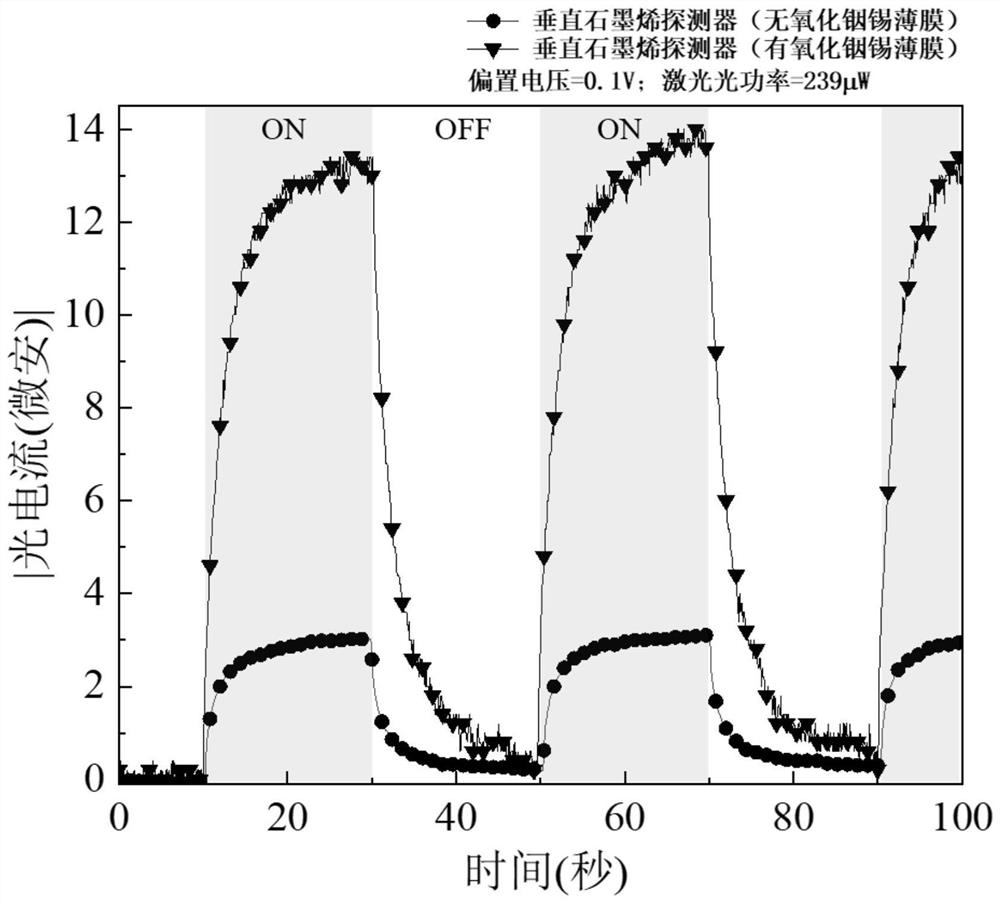

[0042] A vertical graphene photodetector (indium tin oxide-free thin film), the device structure includes: glass as the substrate of the device; vertical graphene as the light absorption layer and electron transport layer of the device; both sides of the vertical graphene are titanium / The gold electrodes are connected to an external power source. refer to image 3 The circular (●) curve in the figure was tested at room temperature and standard atmospheric pressure. A 980nm semiconductor pump laser was used as the test light source. The optical power of the light source was 239μW. Under the external bias voltage of 0.1V, the The generated photocurrent is 3.02μA, and the photoresponsivity is 12.6mA / W.

Embodiment 3

[0043] Embodiment 3: the photocurrent test of vertical graphene photodetector (with indium tin oxide thin film)

[0044] A vertical graphene photodetector (with indium tin oxide film), the device structure includes: glass as the substrate of the device; vertical graphene as the light absorption layer and electron transport layer of the device; the indium tin oxide film as the transparent current diffusion layer; on both sides of the vertical graphene are titanium / gold electrodes connected to an external power source. refer to image 3 The triangle (▼) curve in the figure is tested at room temperature and standard atmospheric pressure. A 980nm semiconductor pump laser is used as the test light source. The optical power of the light source is 239μW. Under the external bias voltage of 0.1V, the The photocurrent is 13.4μA, and the photoresponsivity is 56.1mA / W.

[0045] Show according to the experimental result of embodiment 2 and 3, the photoelectric current that the vertical g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com