Ultrasonic inspection device

一种检查装置、超声波的技术,应用在测量装置、超声波/声波/次声波的产生、使用声波/超声波/次声波分析固体等方向,能够解决错误剥离等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] First, an embodiment will be described.

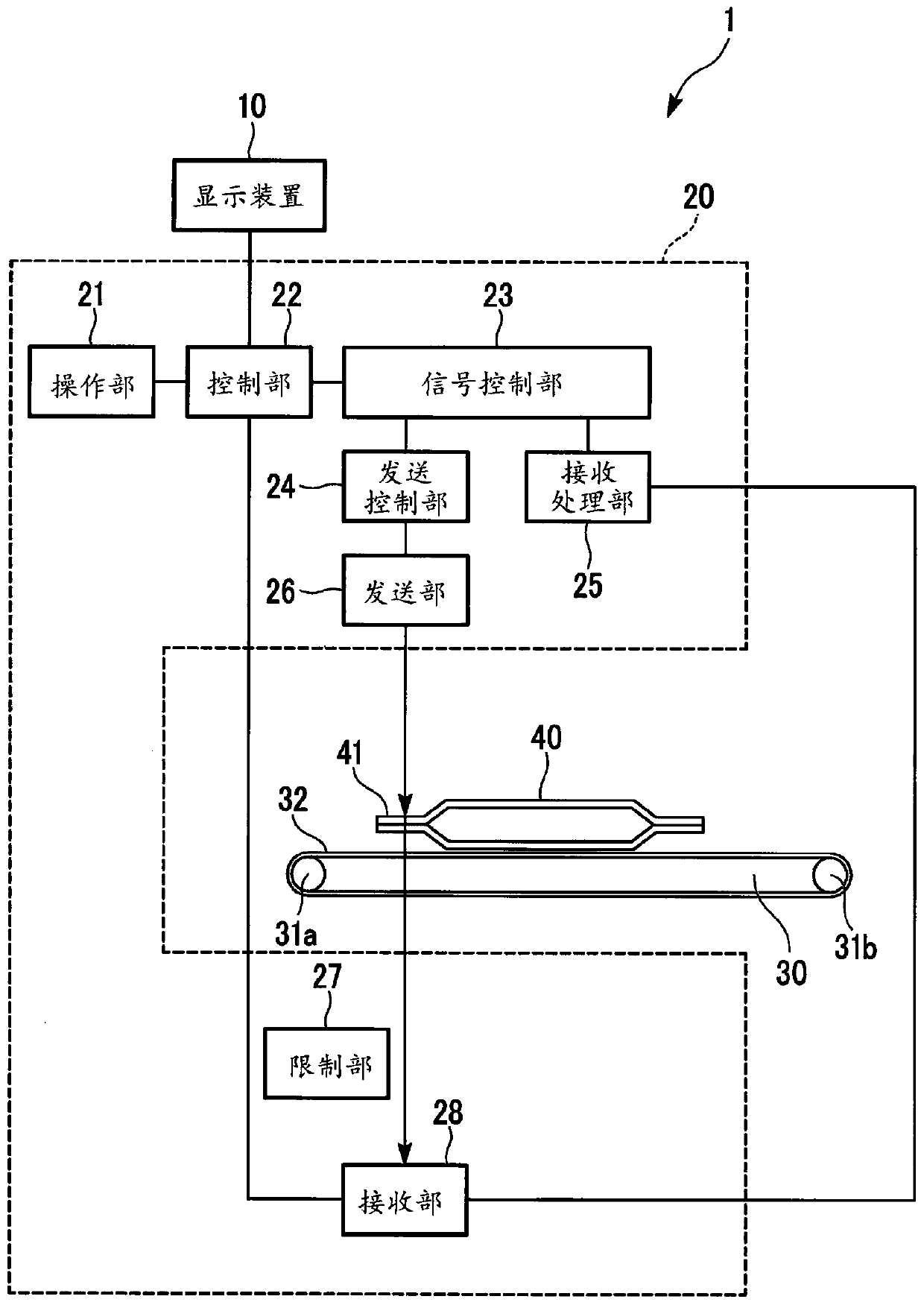

[0040] figure 1 It is a block diagram showing a configuration example of the ultrasonic inspection system 1 according to the embodiment. The ultrasonic inspection system 1 inspects an inspection object 40 using ultrasonic waves. exist figure 1 In the illustrated example, the ultrasonic inspection system 1 includes a display device 10 , an ultrasonic inspection device 20 , and a transport device 30 .

[0041] The display device 10 displays various information related to ultrasonic examination output from the control unit 22 of the ultrasonic examination device 20 . The various information related to the ultrasonic inspection refers to, for example, information related to the inspection object 40, the wavelength or intensity of the transmitted ultrasonic wave, the speed at which the inspection object 40 is transported, the analysis result of the received ultrasonic wave, and the determination of the presence or absence of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com