Wiring module for use in conjunction with contactor and contactor assembly

A contactor and component technology, applied in relays, electrical components, electromagnetic relays, etc., can solve problems such as safety and hidden dangers, and achieve the effect of improving reliability, wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

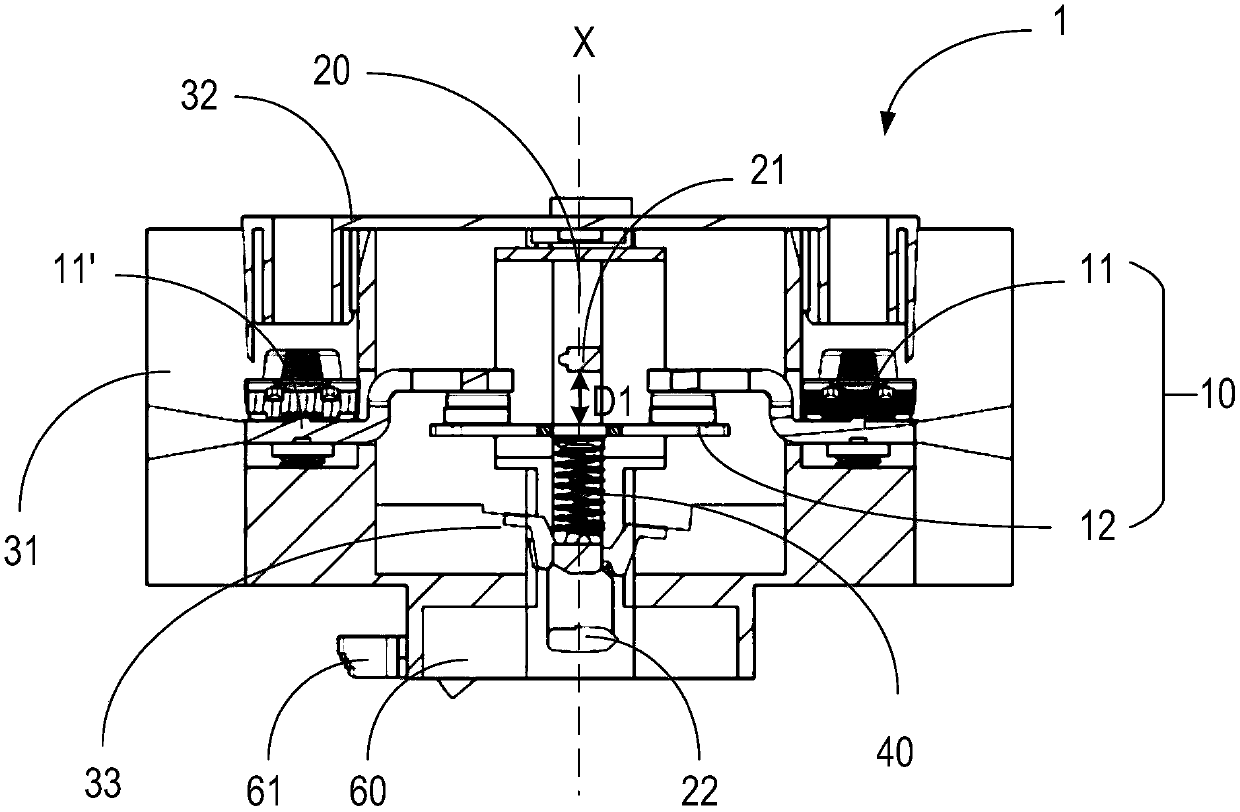

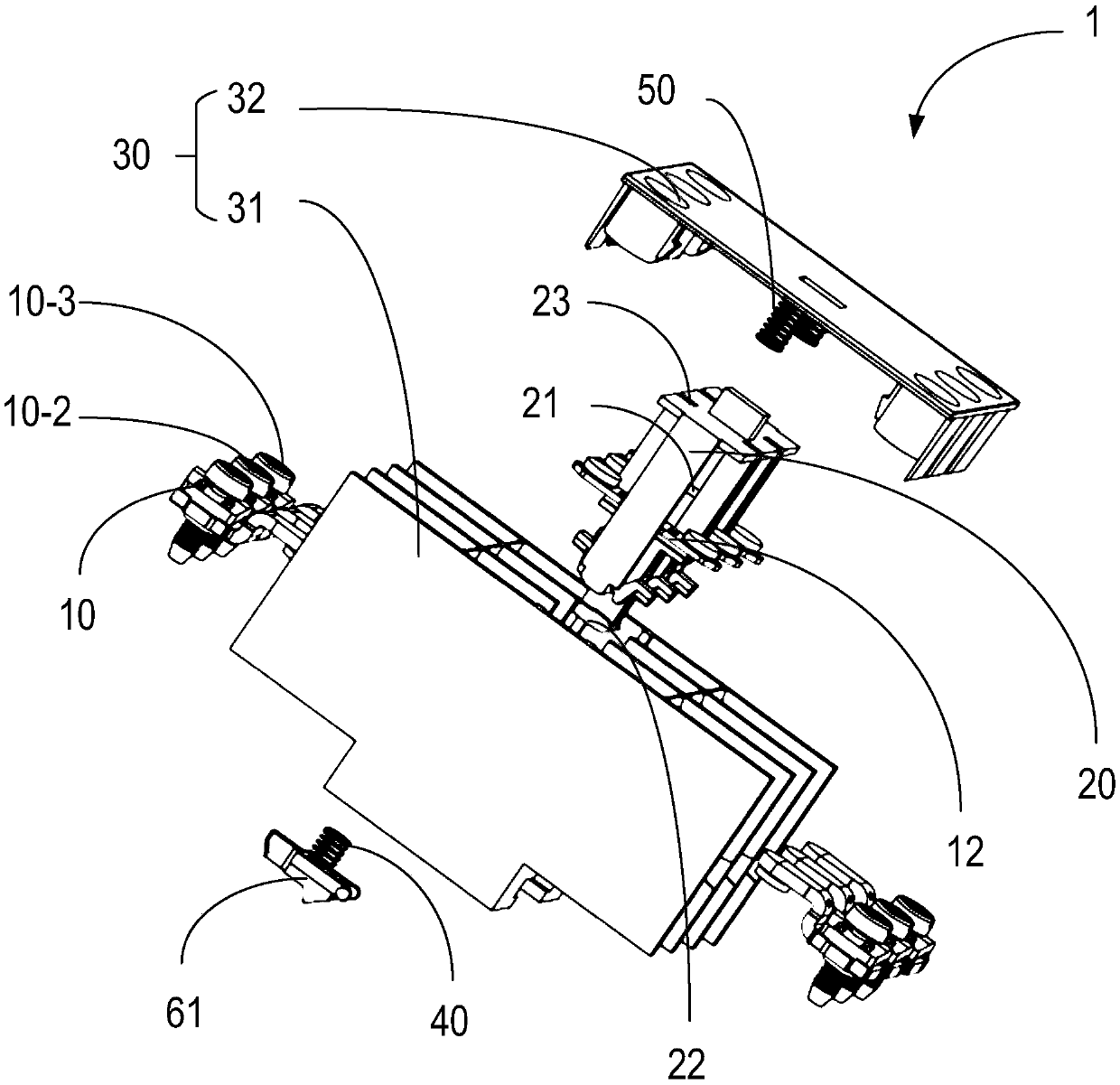

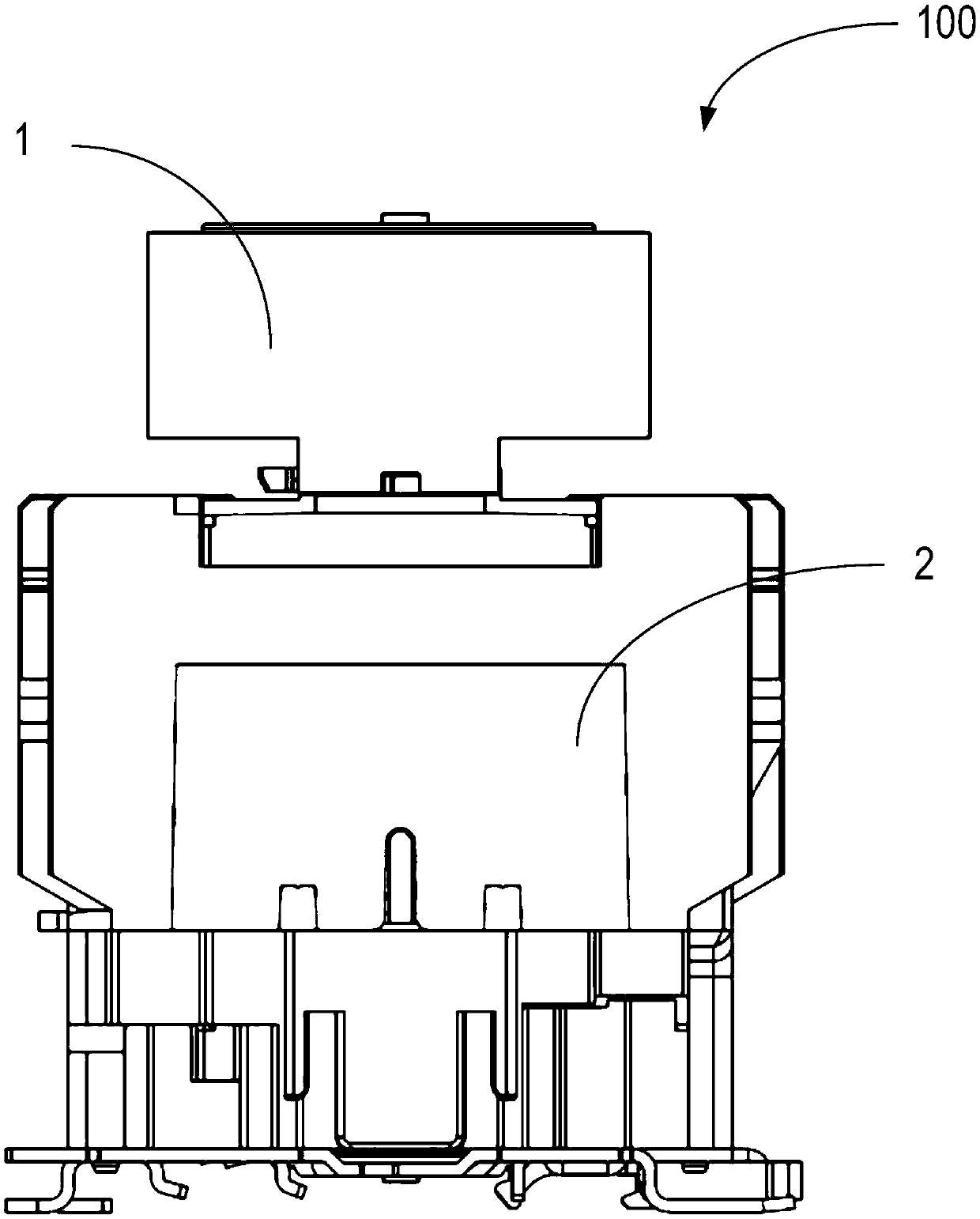

[0026] The principles of the disclosure will now be described with reference to various exemplary embodiments illustrated in the drawings. It should be understood that the descriptions of these embodiments are only for enabling those skilled in the art to better understand and further realize the present disclosure, and are not intended to limit the scope of the present disclosure in any way. It should be noted that similar or identical reference numerals may be used in the figures where feasible, and similar or identical reference numerals may denote similar or identical functions. Those skilled in the art will readily recognize from the following description that alternative embodiments of the structures and methods illustrated herein may be employed without departing from the principles of the disclosure as set forth herein.

[0027] As briefly mentioned above, the inventor noticed that the existing solutions for short-circuiting the permanent magnet synchronous motor after...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap