Socket and headstock component by using same

A technology of sockets and plugs, which is applied to parts of connection devices, electrical components, and two-part connection devices, etc., which can solve the problems of easily damaged insulators, unstable signal and/or electrical transmission, etc., so that it is not easy to loosen and reduce warping The degree of deformation and the effect of avoiding warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

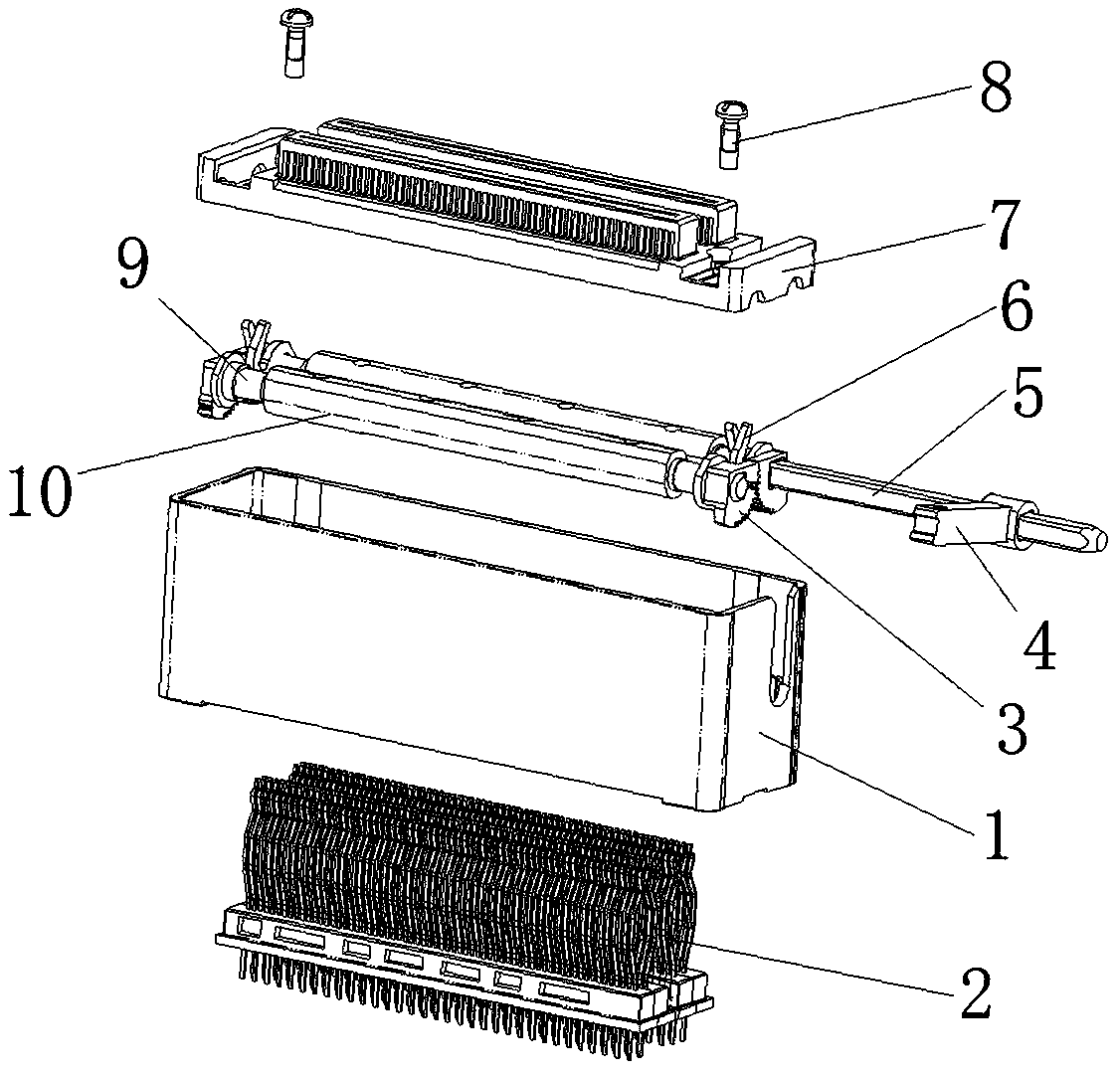

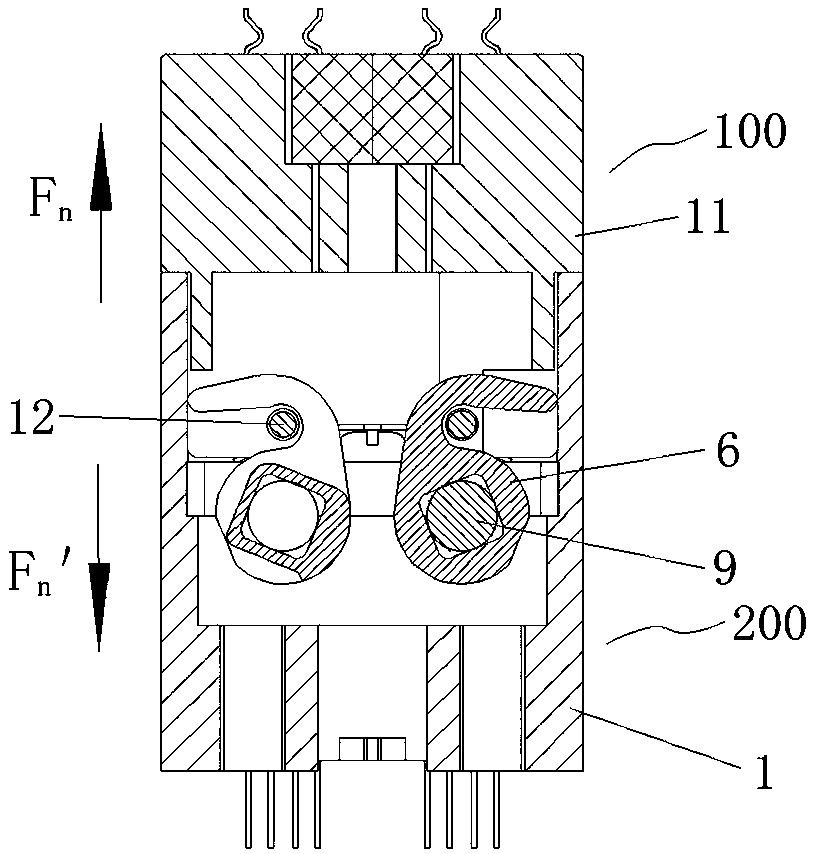

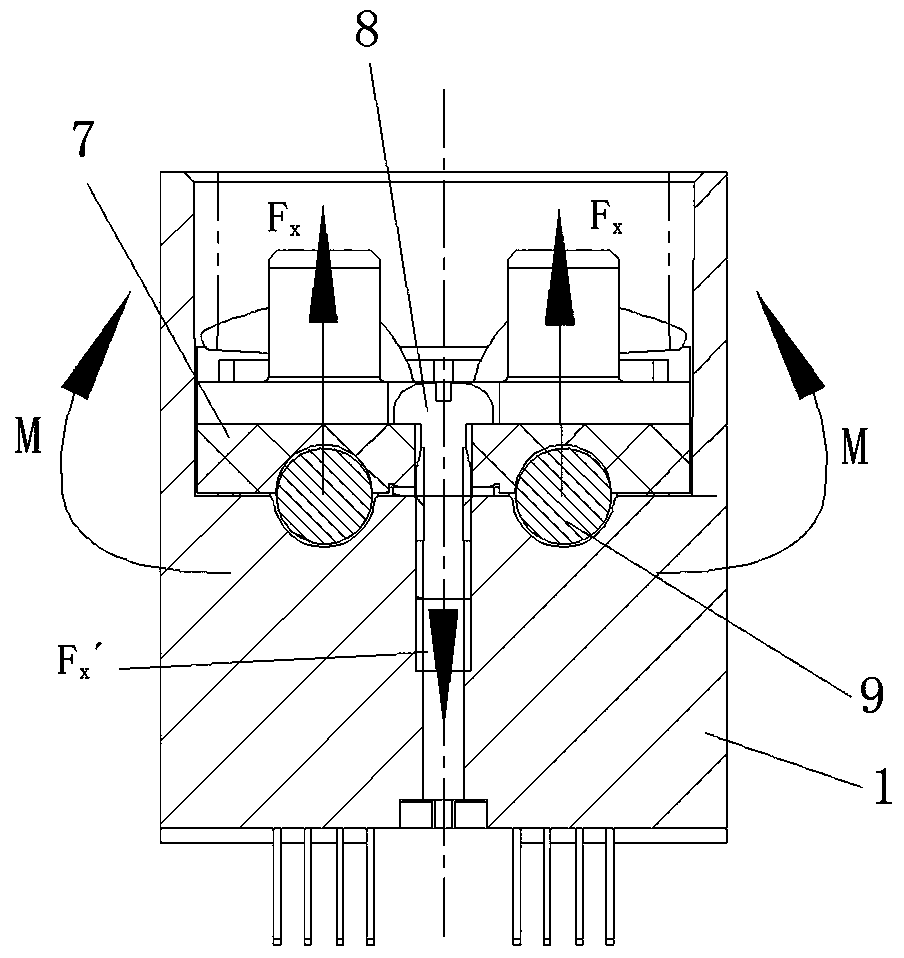

[0055] like Figure 4 to Figure 12 As shown, the header assembly includes a plug 400 and a socket 300 , wherein the structure of the plug 400 is consistent with that in the prior art, and the plug 400 includes a plug housing and a plug contact 41 . Socket 300 includes socket housing 39, wherein, as Figure 7 and Figure 8 As shown, the socket housing 39 includes a housing main body 31 and a supporting wall 32, the housing main body 31 is a box-shaped structure as a whole, the supporting wall 32 is integrally formed with the housing main body 31, and the supporting wall 32 is along the length of the housing main body 31 There are two directions arranged at intervals. Wherein, the structure of support wall 32 is as Figure 8 , Figure 9 and Figure 10 As shown, there are two arc-shaped grooves on the supporting wall 32 for the rotating shaft 36 to be placed in, and play a role in limiting the rotating shaft 36 . Two arc-shaped grooves are arranged at intervals along the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com