Water-cooled cable joint of induction furnace

A technology of water-cooled cables and induction furnaces, which is applied in the direction of cable joints, insulated cables, cables, etc., can solve the problems of customers' economic losses, increase in contact surface resistance, surface oxidation, etc., and achieve the effect of solving joint problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

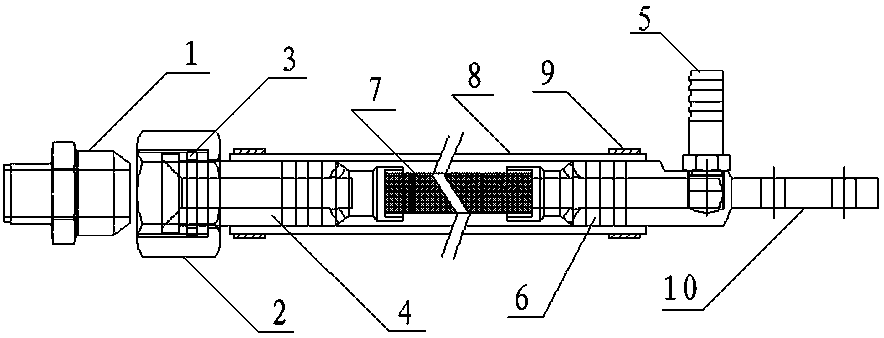

[0015] like figure 1 The shown water-cooled cable joint for an induction furnace includes an inductor end connector, a capacitor end connector, a cable core 7 connecting the inductor end connector and the capacitor end connector, and is sleeved on the inductor end connector and the capacitor end On the connector, the cable core 7 is placed in the water bushing 8, and the water channel is set in the sensor end connector and the capacitor end connector, and the water channel communicates with the water bushing 8 to form a waterway. Connect with cooling equipment to form circulating cooling.

[0016] In the prior art, the cable core passes through natural cooling with a current of 2.5-3A. When it is subjected to high current, it will generate heat and cause surface oxidation. Burn out the water-cooling cable head by igniting it. However, the structural design of the present invention allows the cable core to be cooled by water, and when the cable is cooled by water, it can carr...

Embodiment 2

[0018] As a specific structural design of Embodiment 1, the sensor end connector includes a water nut 1, a nut 2, a washer 3, and a sensor end connecting rod 4, and the sensor end connecting rod 4 includes a socket for connecting water. The rod body of the casing, the rod body is hollow for water passage, located at one end of the rod body, a cylindrical platform with an outer diameter larger than the outer diameter of the rod body, located at the other end of the rod body, a cable connector with an outer diameter smaller than the outer diameter of the rod body, 3 washers and 2 sets of nuts Connected to the sensor connecting rod 4, and the washer 3 is connected to the cylindrical platform, the nut 2 is sleeved outside the washer 3, one end of the water-through nut 1 is welded on the inductor, and the other end is matched and locked with the nut.

[0019] The cable connector of the connecting rod 4 at the sensor end is a hollow cylinder, one end of the cable core is inserted int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com