Industrial camera with protection function

A technology for industrial cameras and protective functions, applied in the field of industrial cameras with protective functions, can solve problems such as damage, short circuit or open circuit, and potential safety hazards of industrial cameras, improve imaging quality and service life, increase air flow rate, speed up The effect of heat exchange frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following will further describe the embodiments of the present invention in detail with reference to specific embodiments and drawings.

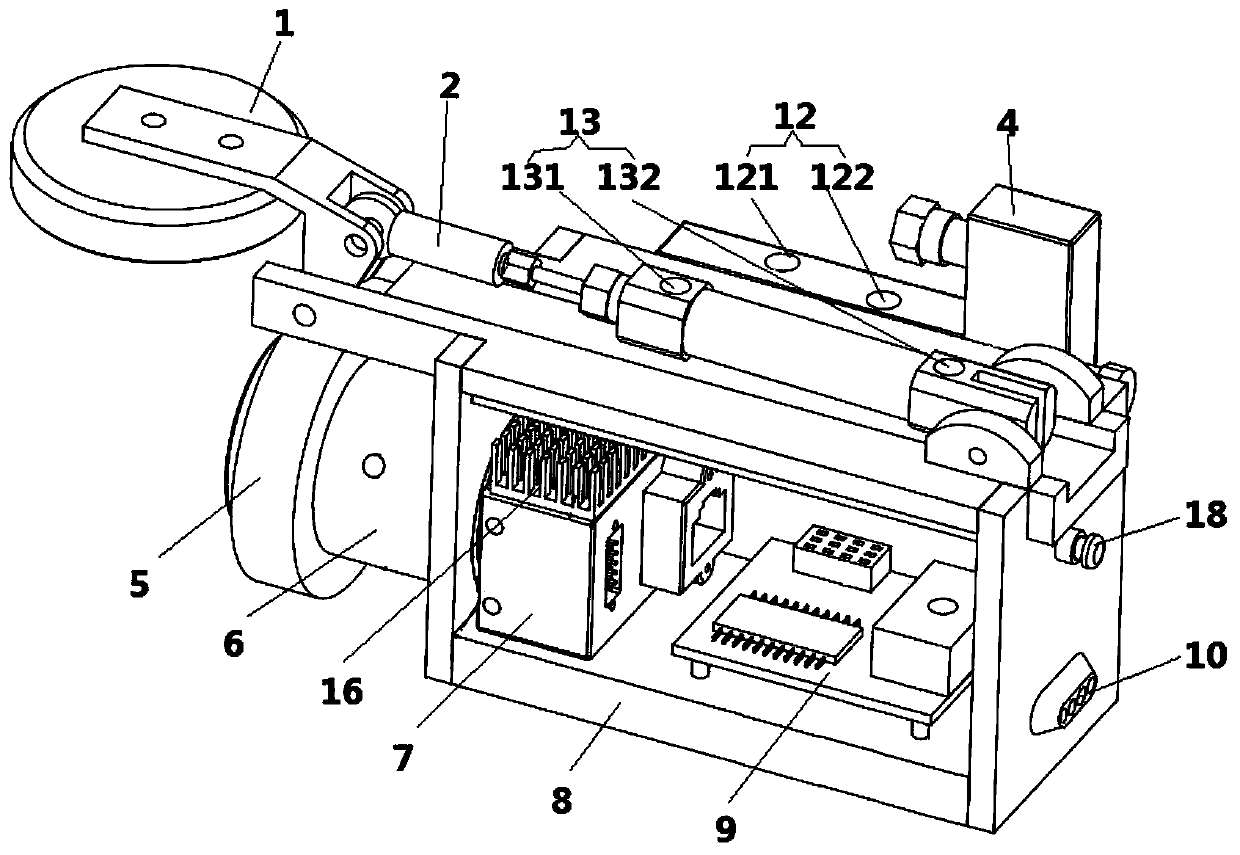

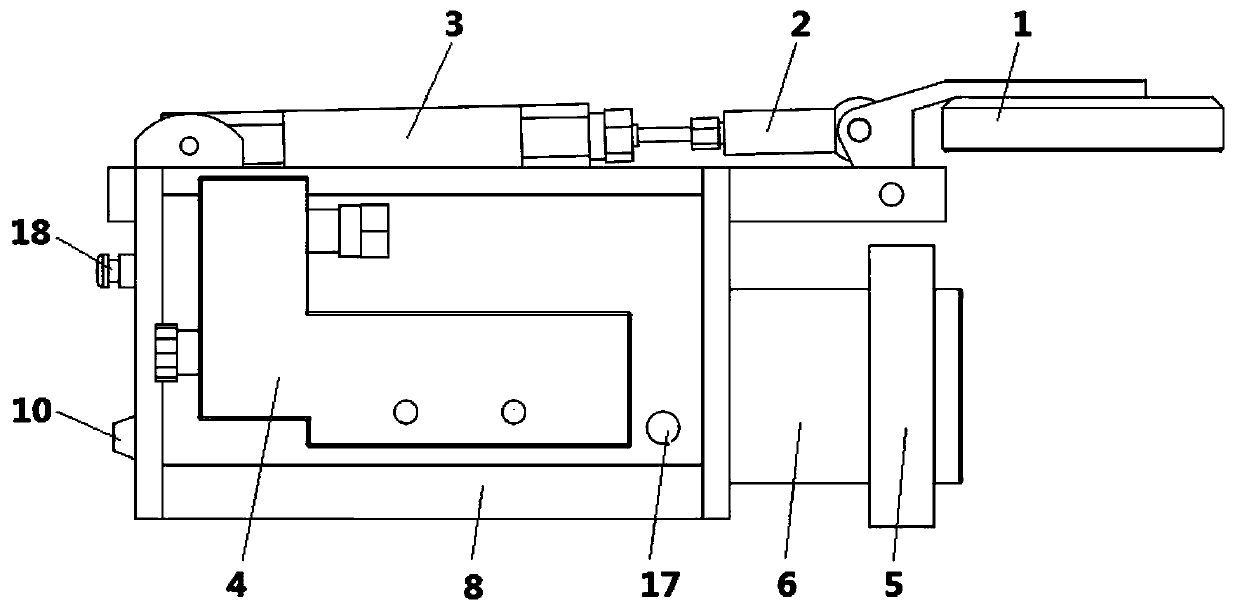

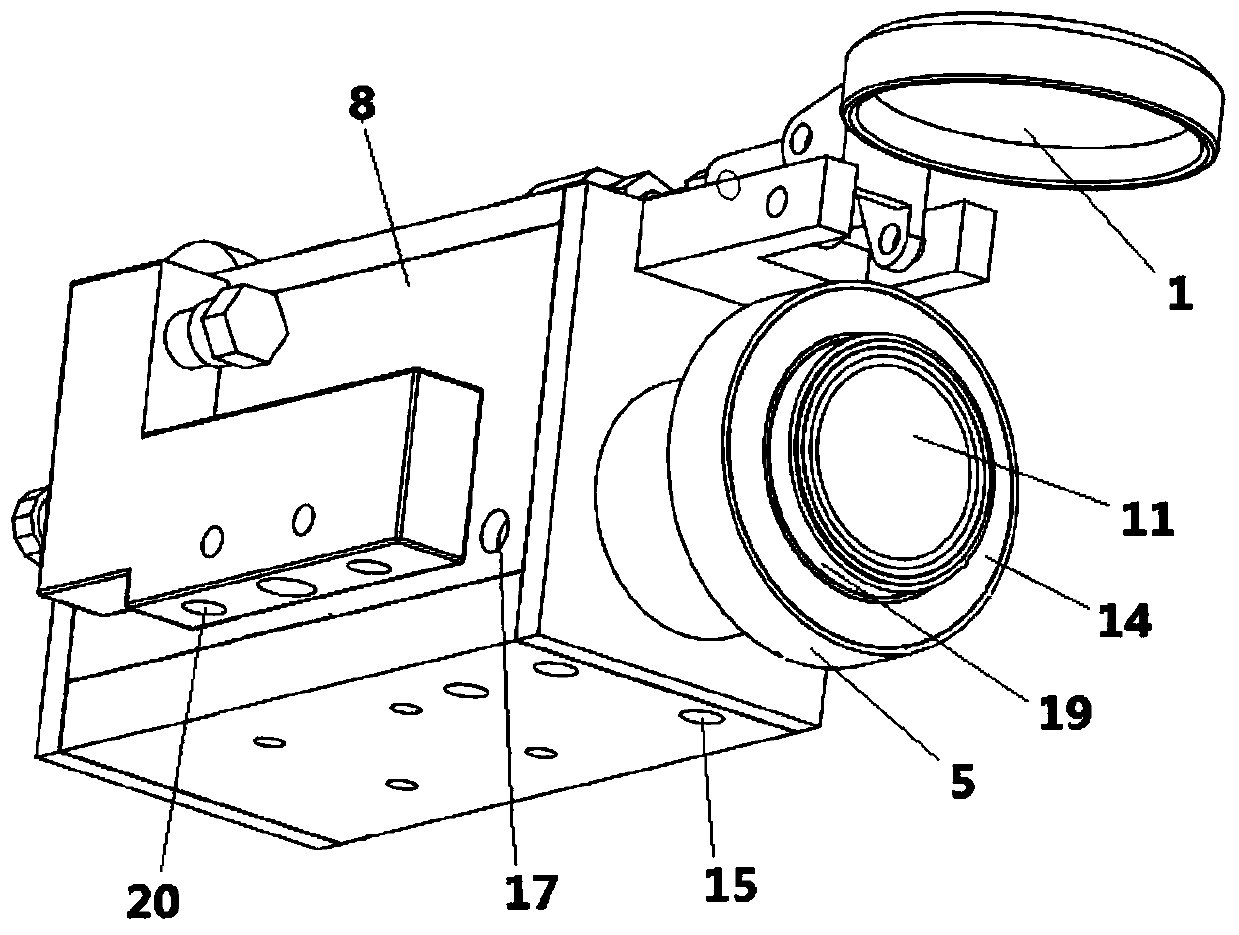

[0040] An industrial camera with a protective function, including a protective cover body, a pneumatic system, an auxiliary light source, an internal control system, and industrial camera components. The protective cover body includes a protective cover shell 8, which is composed of a front panel and a rear panel. , The left side plate, the right side plate, the top plate and the bottom plate are sealed and spliced together. The front end plate has a lens hole. The inner wall of the lens hole is threaded and connected with a lens sleeve. The inner wall of the front end of the lens sleeve 6 is threaded with a hood 11 and a lens sleeve. The front end of the barrel 6 is hinged with a lens protection cover 1, and the rear end plate is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com