Karst tunnel drainage type drainage system

A drainage system and tunnel technology, applied in tunnels, drainage, tunnel lining and other directions, can solve the problems of difficult drainage of karst tunnels, and achieve the effects of improving drainage efficiency, expanding the scope of influence, and efficient drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

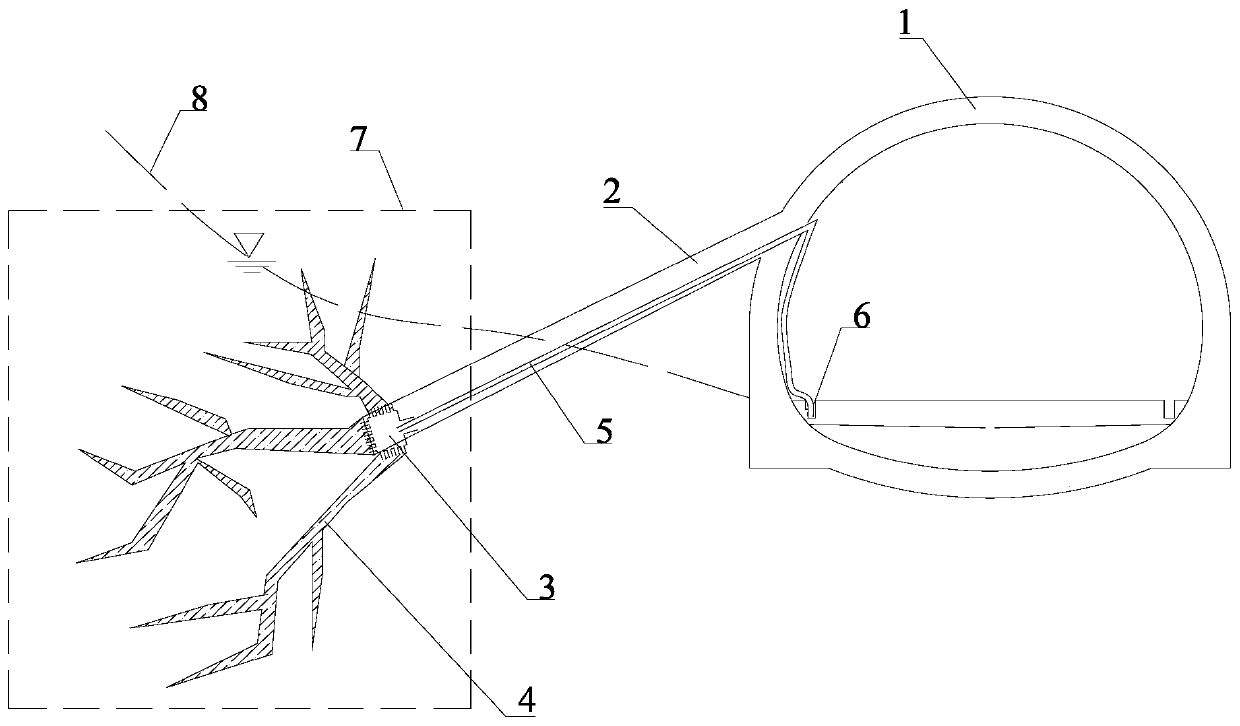

[0041] A karst tunnel drainage system includes a borehole 2, a drainage network, a drainage pipe 5 and a tunnel drainage ditch.

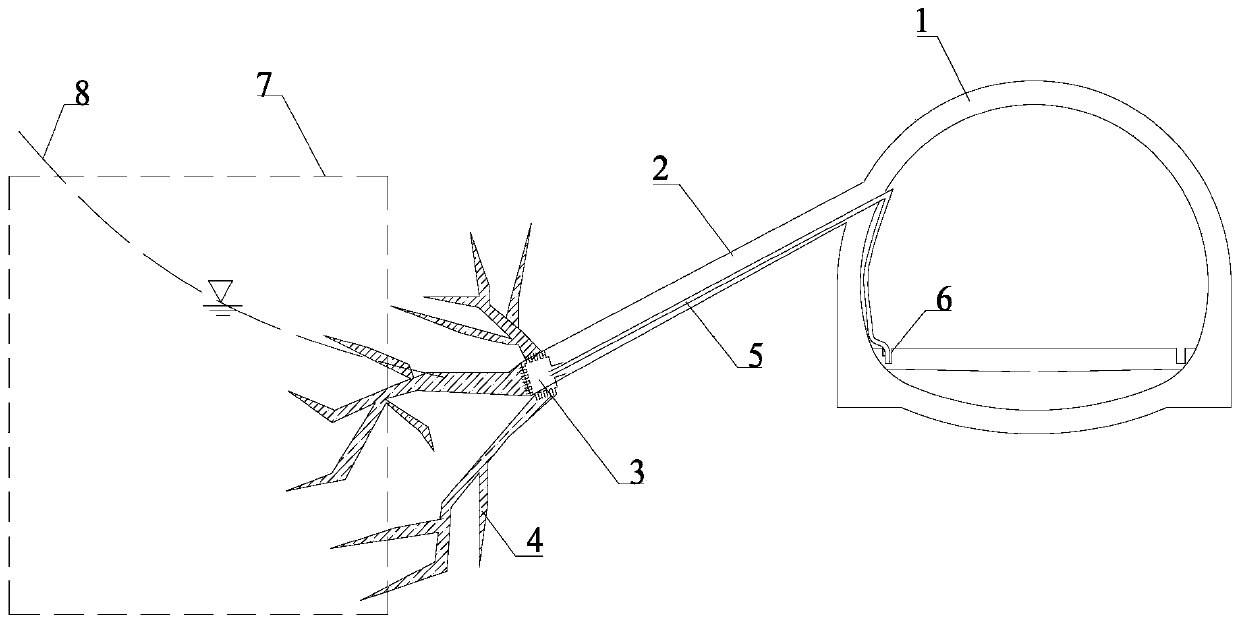

[0042] The borehole 2 is a downhill borehole, the inclination angle of the borehole 2 is 10°-30°, and the diameter of the borehole 2 is greater than or equal to 70mm. The borehole 2 is directly drilled into the karst development area 7 of the tunnel 1, such as figure 1 shown; or the borehole 2 is not drilled into the karst development area 7 of the tunnel 1, but is located near the karst development area 7, as figure 2 mentioned.

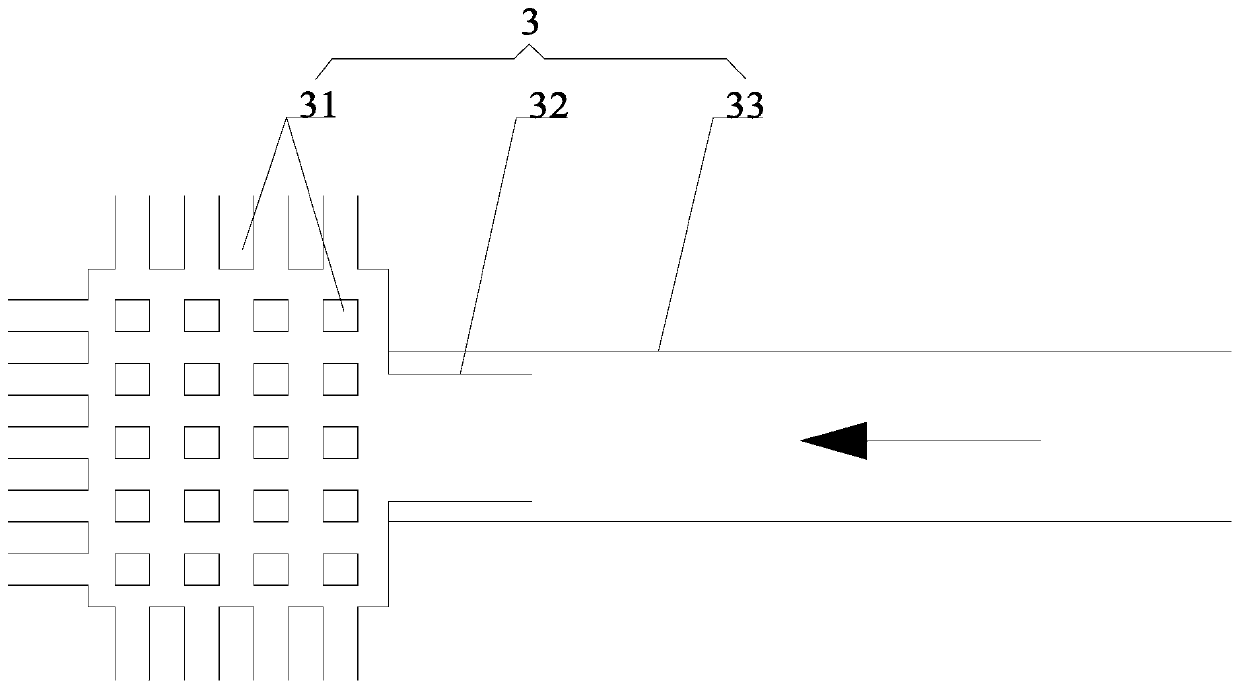

[0043] The bottom end of the borehole 2 is provided with a multi-nozzle casing 3, such as image 3As shown, the multi-nozzle sleeve 3 includes a grouting hole 31 , a plurality of injection holes 32 and a movable sleeve 33 , and all the injection holes 32 are arranged circumferentially along the multi-nozzle sleeve 3 . The grouting hole 31 is located in the borehole 2, the grouting hole 31 and the movable sleeve 33 are...

Embodiment 2

[0049] Such as Figure 1-Figure 5 Shown, a kind of karst tunnel drainage type drainage method comprises the following steps:

[0050] Step 1: Preliminarily determine the karst-developed area 7 of the tunnel 1 according to the geological survey results, and drill a down-dip borehole 2 from the arch wall of the tunnel 1 toward the karst-developed area 7 . If the borehole 2 can be drilled directly to the karst development area 7, then directly drill to the karst development area 7, if the borehole 2 cannot be directly drilled to the karst development area 7, then try to Drilling is carried out near the karst development area 7, so that after the permeable concrete 4 is injected, the drainage network formed can be at least partly located in the karst development area 7, thereby leading out the groundwater in the karst development area 7.

[0051] Step 2: Place a multi-nozzle casing 3 at the bottom of the borehole 2, the multi-nozzle casing 3 includes a grouting hole 31, a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com