Horizontal roller hearth furnace for heat treatment of aluminum plates

A horizontal, roller hearth furnace technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems that the atmosphere cannot be heated up quickly, the temperature uniformity, the surface of the plate is damaged, and the mechanical properties of the plate are not optimal. The effect of manual maintenance and optimization of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

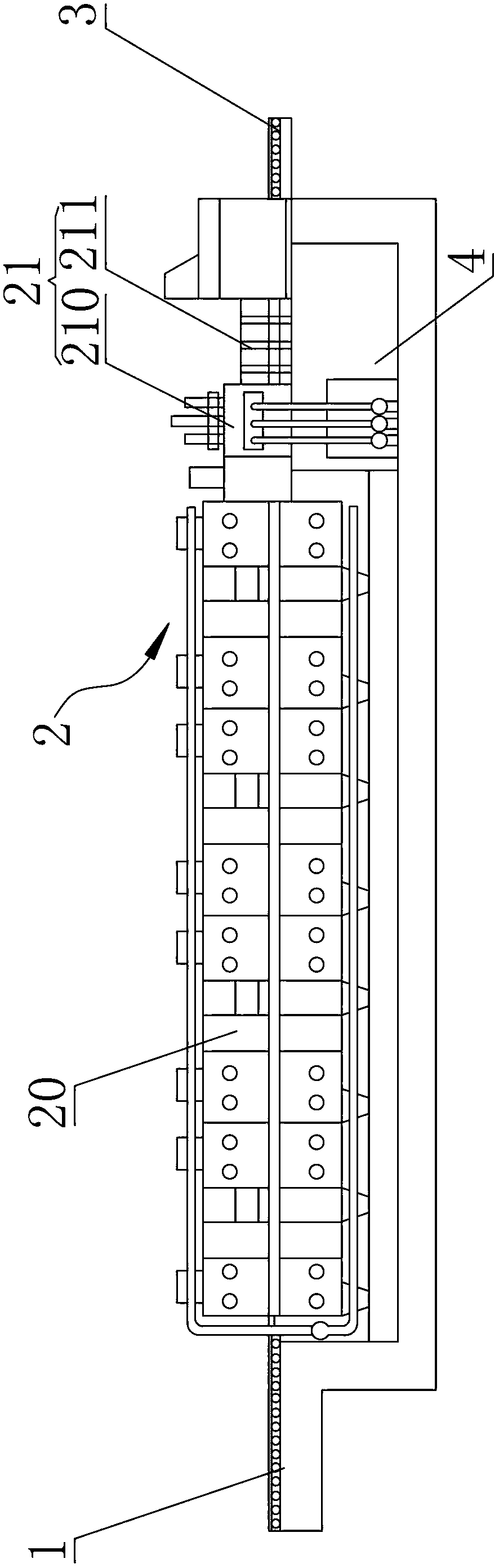

[0025] As shown in the figure, a horizontal roller hearth furnace for heat treatment of aluminum plates includes a charging platform, a furnace body 2 and a discharging platform arranged in sequence, wherein:

[0026] Charging platform: including charging roller table 1, which extends to furnace body 2, charging roller table 1 is made of stainless steel tube, and is equipped with a heat-resistant plate, which can effectively prevent damage to the lower surface of the plate during transportation; The two ends of the rollers of the material roller table 1 are equipped with automatic centering bearings, the thrust bearings are installed on the connecting sleeve, and the driving side bearings are fixed; the labyrinth rubber seal is used to seal between the furnace body 2 and the rollers, and the plate is sealed by a special The hoisting device is hoisted on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com