Lighting device and linked lighting device

A technology for lighting devices and power supply devices, which is applied to the cooling/heating devices of lighting devices, lighting devices, components of lighting devices, etc., which can solve the problems of reduced energy conversion efficiency and shortened life of light-emitting elements, and achieve the purpose of suppressing height dimensions, Good effect on cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

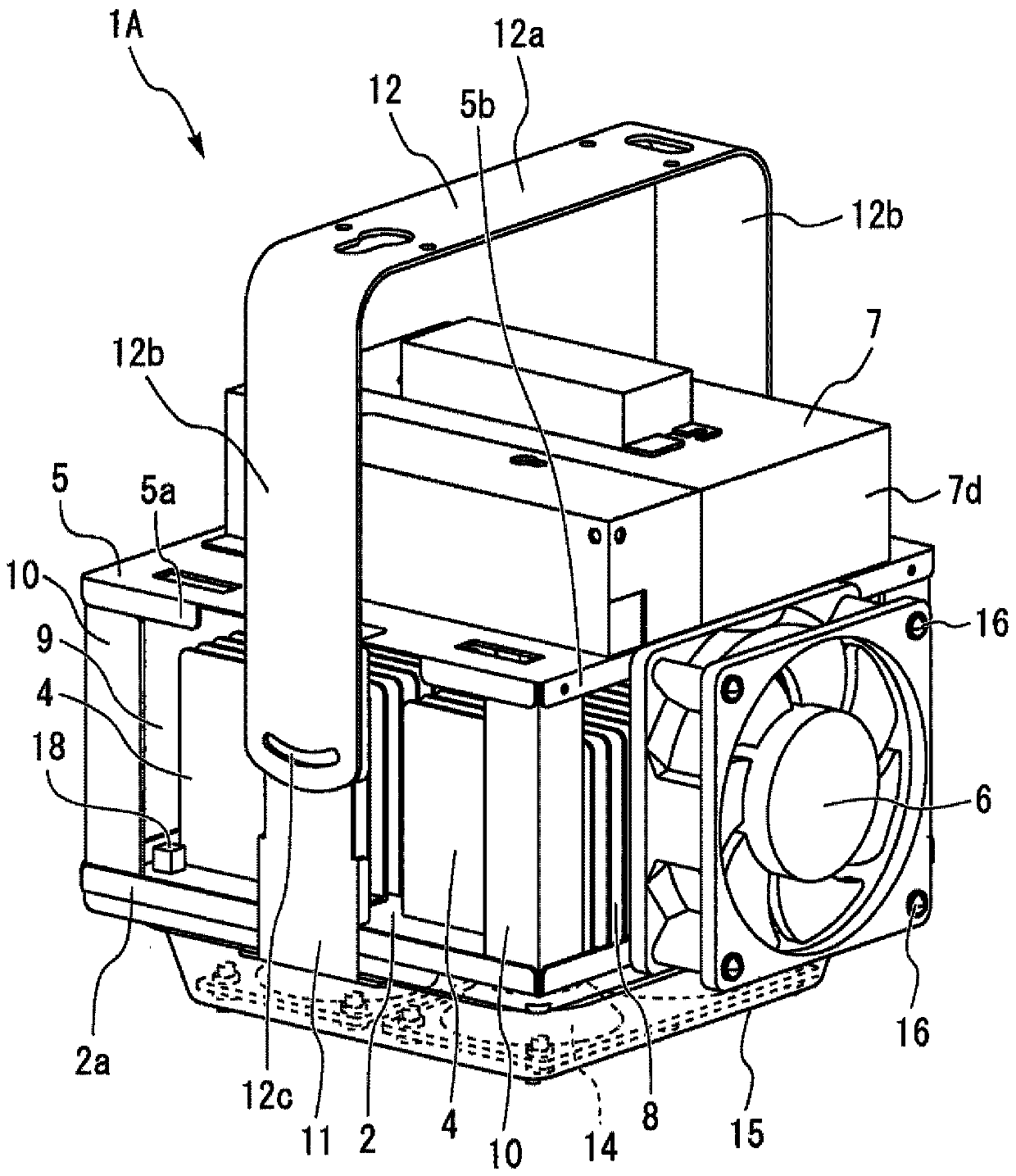

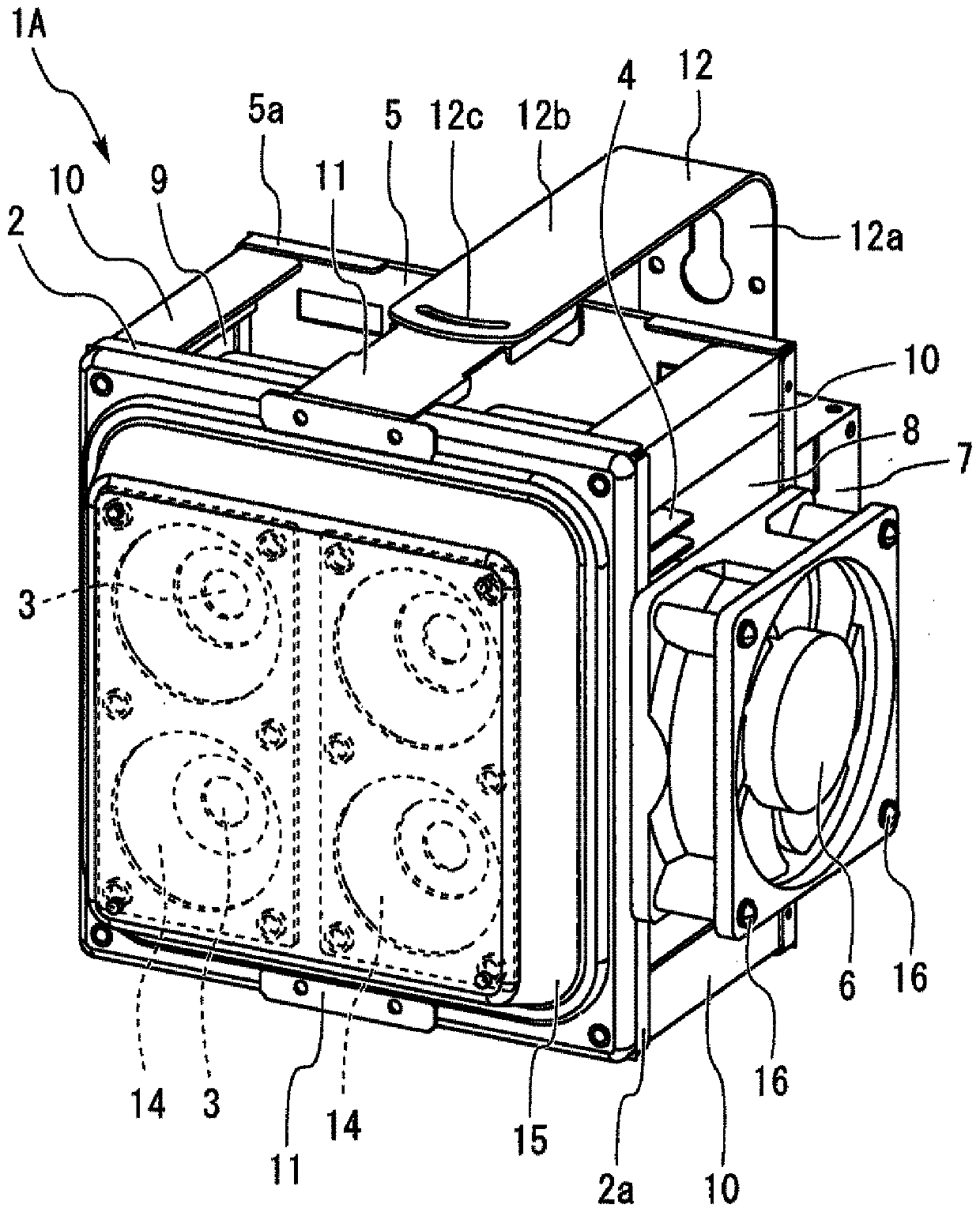

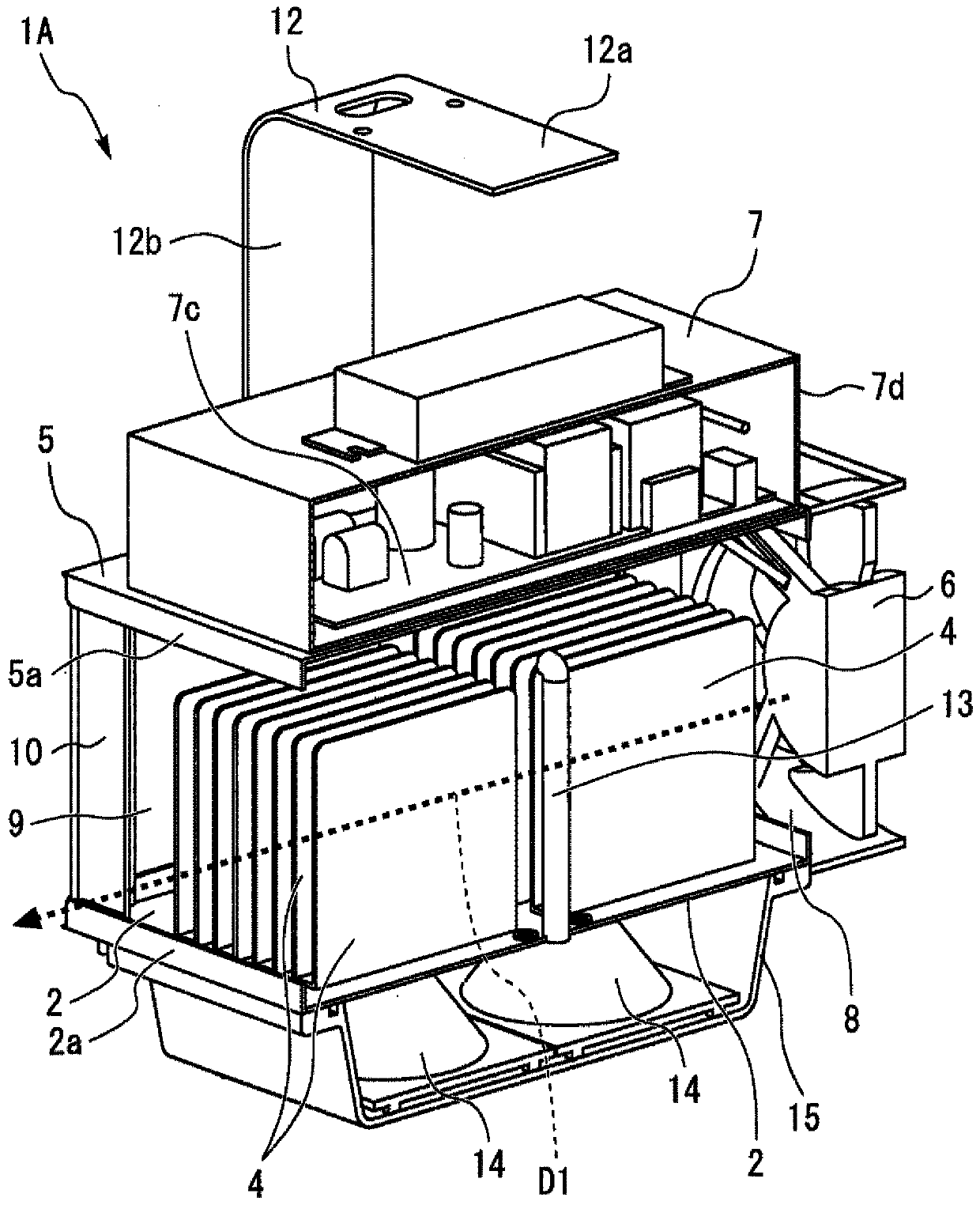

[0031] figure 1 It is a perspective view of the lighting device 1A according to Embodiment 1 viewed obliquely from above. figure 2 It is a perspective view of the lighting device 1A according to Embodiment 1 viewed obliquely from below. image 3 It is a cutaway perspective view of the lighting device 1A according to the first embodiment. Figure 4 It is a functional block diagram of the lighting device 1A according to the first embodiment. The lighting device 1A of Embodiment 1 shown in these figures is installed on the ceiling, and can be preferably used for illuminating the space below the lighting device 1A by irradiating light downward. In the following description, the up and down directions are determined based on the posture when the lighting device 1A is used. The lighting device 1A can be suitably used, for example, as a device that emits light beams of several thousand lumens to tens of thousands of lumens. The lighting device 1A is particularly suitable for ins...

Embodiment approach 2

[0078] Next, refer to Figure 6 Embodiment 2 will be described, focusing on differences from Embodiment 1 described above, and descriptions of the same parts or corresponding parts will be simplified or omitted. Figure 6 It is a perspective view of the lighting device 1B according to Embodiment 2 viewed obliquely from above.

[0079] Such as Figure 6 As shown, the cooling fan 6 included in the lighting device 1B of the second embodiment is provided at a slightly higher position than that of the first embodiment. The upper end of the cooling fan 6 is located higher than the second base 5 . The lower end of the cooling fan 6 is at a height between the first base 2 and the second base 5 . The cooling fan 6 is fixed to the power supply housing 7d with two screws 16 . The cooling fan 6 has a portion facing the power supply housing 7 d and a portion facing the first vent 8 .

[0080] Part of the airflow generated by the cooling fan 6 is in contact with the surface of the powe...

Embodiment approach 3

[0084] Next, refer to Figure 7 Embodiment 3 will be described with a focus on differences from Embodiment 1 described above, and descriptions of the same parts or corresponding parts will be simplified or omitted. Figure 7 It is a side view of the lighting device 1C according to the third embodiment.

[0085] Such as Figure 7 As shown, the illuminating device 1C according to the third embodiment differs from the first embodiment in that the center line AX of the cooling fan 6 is not inclined in parallel to the first base 2 . The center line AX is inclined so as to approach the first base 2 as it moves away from the cooling fan 6 .

[0086] A plurality of imaginary trajectories obtained by parallel moving a plurality of points in the area inside the air outlet of the cooling fan 6 toward the direction in which the airflow blows out from the air outlet of the cooling fan 6 includes the intersection with the first base 2. The trajectory L1 and the trajectory L2 passing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com